9

Heat Controller, Inc. VMH 30/36 SERIES Installation, Operation & Maintenance

AIR PURGING

5

Open the valve stem until it hits against

the stop. Do not try to open it further.

Securely tighten the valve stem cap with

a spanner or wrench.

See tightening torque table on page 8 to

properly tighten and torque the valve stem cap.

Flare nut

Stop

Cap

Valve body

Valve stem

Ensure any R-410A refrigerant is added to the unit in liquid form.

Air and moisture in the refrigerant system have undesirable effects. Therefore, the indoor unit

and tubing between the indoor and outdoor unit must be leak tested and evacuated to remove

any noncondensables and moisture from the system.

Check that each tube(both l

iquid and gas side tubes) between the indoor and outdoor units have

been properly connected and all wiring for the test run has been completed.

Pipe length and refrigerant amount:

Units are pre-charged for 16.5 ft. (5m) total line set length, additional charge is needed for longer

line sets lengths. Charge adjustments are not required for line sets less than 16.5 ft (5m)

Outdoor

unit

Indoor

unit

Refrigerant

Packed valve

Half union

Gas side

Liquid side

A

C

D

B

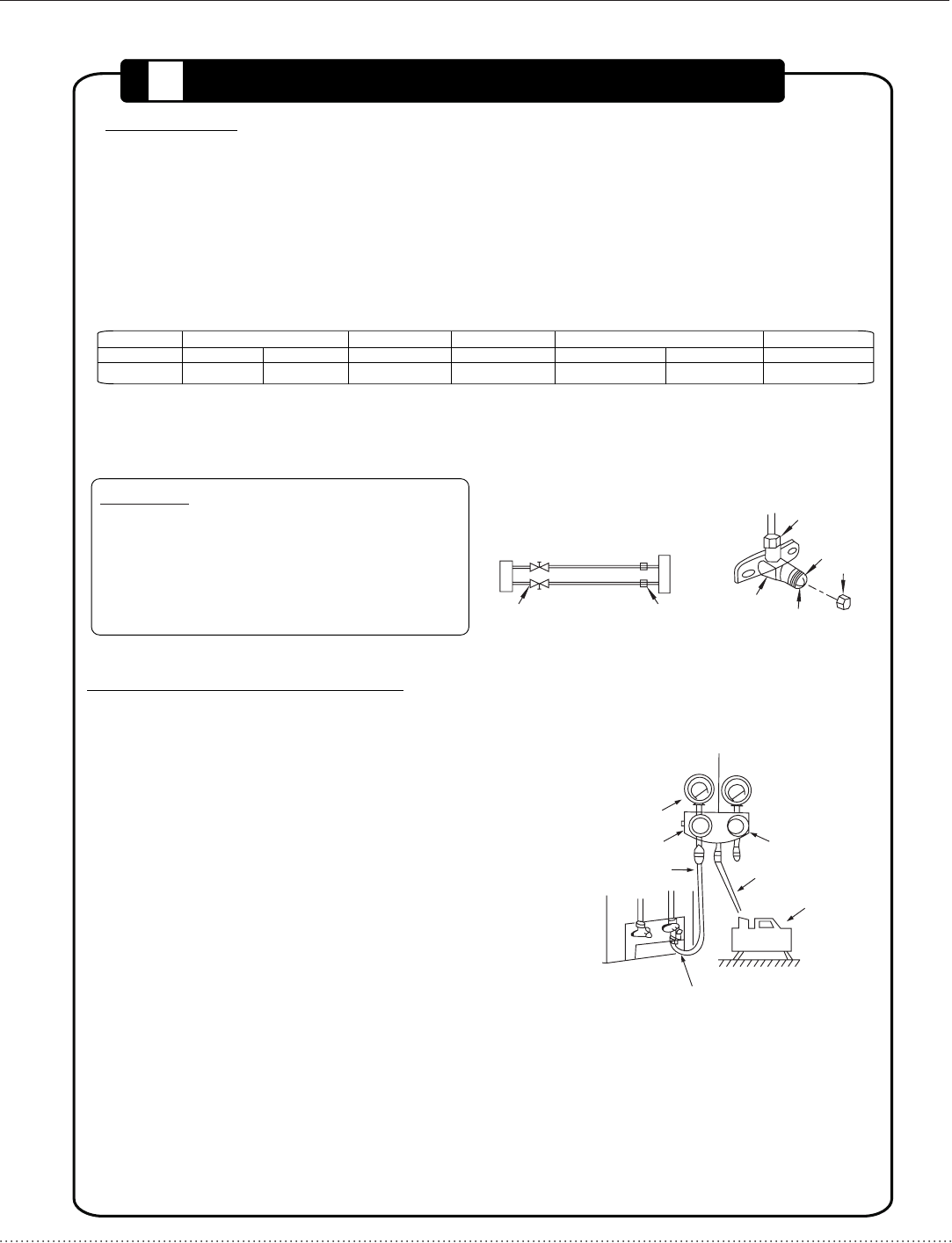

NOTE: Refer to the manifold valve manufacturer’s instructions before use.

1. Completely tighten the flare nuts, A, B, C, D, (see figure

on page 10) connect the manifold valve charge hose to a

cha

rge port of the low pressure valve on the gas side.

2. Connect the charge hose connection to the vacuum

pump.

3. Fully open the handle of the manifold valve.

4. Operate the vacuum pump to evacuate. After starting

evacuation, slightly loose the flare nut of the low pressure

valve on the gas side and check that the air is

entering. (Operation noise of the vacuum pump changes

and a compound meter indicates 0 instead of minus)

5. After the evacuation is complete, fully close the lo handle

of the manifold valve and stop the operation of the

vacuum pump.

Evacuate for 15 minutes and more and check

th

at the compound meter indicates -29.92inHg(-76cmHg).

O

6. Turn the stem of the low pressure valve B about 45 counter-

clockwise for 6~7 seconds after the gas units out, then

tighten the flare nut again. Make sure the pressure display

in the pressure indicator is a little higher than the atmosphere

pressure.

7. Remove the charge hose from the Low pressure charge hose.

8. Fully open the packed valve stems B and A.

9. Securely tighten the cap of the packed valve.

Lo

Manifold valve

Compound meter

-29.92 inHg

*(-76cmHg)

Lo Handle

Hi Handle

Charge hose

Charge hose

Vacuum pump

Pressure gauge

Low pressure valve

1. Air purging

2. When using the Vacuum Pump

CAUTION

Pipe Size

Gas (in) Liquid (in)

5/8 (16mm) 3/8(9.52mm)

Max

Elevation (ft)

32 (9.75m)

Total Line Length (ft)

Min. Max.

10 (3m) 82 (25m)

Capacity

Btu/h

30-36k

Standard

Length (ft)

*16.5 (5m)

Additional

Refrigerant oz/ft

.4 (40g/m)

*Unit charge located on rating plate includes enough refrigerant for 16.5 feet of line set.

* Charge adjustment is not required on line set lengths less than 16.5 feet.

OUTDOOR SECTION