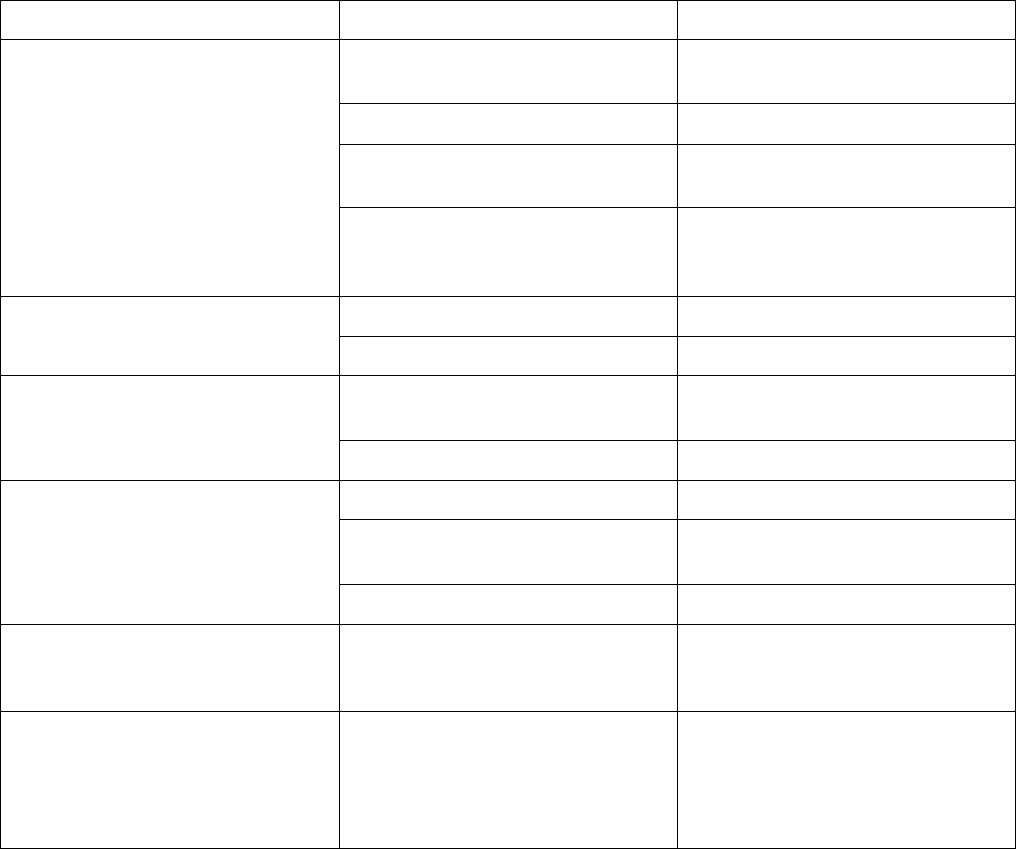

Troubleshooting

310622L 15

PROBLEM

CAUSE SOLUTION

Leak in inlet or outlet sanitary fit-

ting.

Loose sanitary clamp. Tighten clamp.

Damaged or worn gasket. Replace gasket.

Misalignment of inlet/outlet hose or

pipe.

Use flexible hoses at pump inlet

and outlet.

Gasket does not seal. Use a standard sanitary gasket of

flexible material such as EPDM,

Buna-N, fluoroelastomer, or silicon.

Fluid in exhaust air. Diaphragm ruptured. Replace. See page 21.

Loose diaphragm plate. Tighten or replace. See page 21.

Pump exhausts excessive air at

stall.

Worn air valve block, plate, pilot

block, u-cups, or pilot pin o-rings.

Repair or replace. See page 16.

Worn shaft seals. Replace. See page 21.

Pump leaks air externally. Air valve cover is loose. Tighten screws. See page 16.

Air valve gasket or air cover gasket

is damaged.

Inspect; replace. See page 16.

Air cover clamps are loose Tighten clamps.

Pump leaks fluid externally from

ball check valves.

Loose manifolds, damaged seal

between manifold and seat, dam-

aged gaskets.

Tighten manifold clamps or replace

seats or clamps (32). See page 19.

Chattering. Check balls not seating prop-

erly/cleanly due to imbalance

between fluid inlet and outlet line

sizing. Noise is accentuated with

light viscosity fluids.

Reduce size/diameter of inlet line

relative to outlet line. Outlet line

size should not exceed pump size.