19

Model VSU Make-Up Air

®®®®®

Bearings

The bearings for Greenheck fans are carefully selected

to match the maximum load and operating conditions

of the specific class, arrangement and fan size. The

instructions provided in this manual and those provided

by the bearing manufacturer will minimize any bearing

problems.

IMPORTANT

Lubricate bearings prior to periods of extended

shutdowns or storage and rotate shaft monthly to

aid in corrosion prevention. If the fan is stored more

than three months, purge the bearings with new

grease prior to start-up.

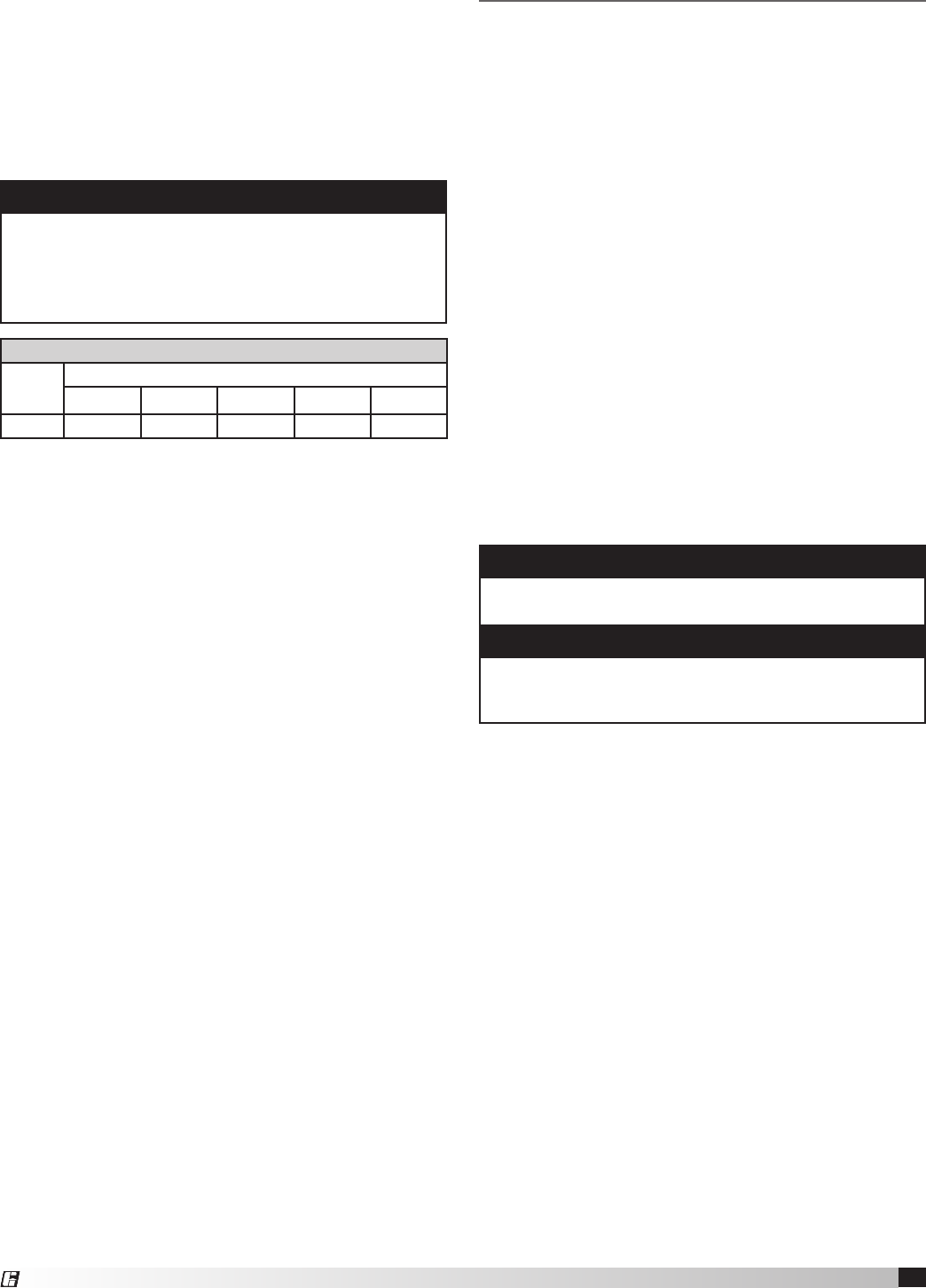

Recommended Bearing Lubrication Schedule (in Months*)

Fan

RPM

Bearing Bore Size (inches)

1

⁄2 - 1 1

1

⁄8 - 1

1

⁄2 1

5

⁄8 - 1

7

⁄8 1

15

⁄16 - 2

3

⁄16 2

7

⁄16 - 3

750 6 5 4 3 3

*Suggested initial greasing interval is based on 12 hour per

day operation and 150°F maximum housing temperature.

For continuous (24 hour) operation, decrease greasing

interval by 50%

• If extended grease lines are present, relubricate while in

operation, only without endangering personnel.

• For ball bearings (operating) relubricate until clean grease

is seen purging at the seals. Be sure not to unseat the seal

by over lubricating.

• For ball bearings (idle) add 1-2 shots of grease up to

2 inch bore size, and 4-5 shots above 2 inch bore sizes

with a hand grease gun.

• For roller bearings add 4 shots of grease up to 2 inch bore

size, and 8 shots for 2-5 inch bore size with a hand grease

gun.

• Adjust relubrication frequency based on condition of

purged grease.

• A high quality lithium based grease conforming to NLGI

Grade 2 consistency, such as those listed here:

Mobil 532

Mobilux #2

Texaco Multifak #2

Texaco Premium #2

B Shell Alavania #2

Exxon Unirex #2

Maintenance - Fall

Start-Up

Repeat the Blower Start-Up Step #5 and Direct Gas Start-

Up Steps #1 through #4. This will ensure that the gas and

air are set properly before the heating season begins and

should lead to trouble free operation all winter.

High Limit

The high limit switch may have tripped over the

summer; it should be checked and reset if necessary.

Burner

Inspect the burner for accumulation of scales on both

the upstream and downstream sides of the mixing

plates. Any scaling or foreign material should be

removed with a wire brush.

Visually check that all holes in the mixing plates are clear.

If any burner ports are plugged (even partially), clear

them with a piece of wire or another appropriate tool.

Replace or tighten any loose or missing fasteners on

the mixing plates. Always use zinc plated or stainless

steel fasteners.

Inspect and clean the flame and spark rod. Occasional

replacement of the flame rod and spark rod may be

necessary to ensure optimum unit performance.

WARNING

Do not enlarge burner ports when clearing a

blockage, performance could be affected.

NOTE

Flame rods can last many years, but because of

thermal expansion of the porcelain, flame rods can

fail over time.