10

Model MSCF Modular Small Cabinet Fan

®

any two supply power connections will reverse the

direction of rotation.

To reverse the rotation, turn the power off and use the

following procedure:

• Forsinglephaseunits,rewirethemotorperthe

instructions on the motor.

• Forthreephaseunits,interchangeanytwo

power leads. This can be done at the motor

starter.

3. Check for Vibration

Check for unusual noise, vibration or overheating of

bearings. Excessive vibration may be experienced

during initial start-up. Left unchecked, excessive

vibration can cause a multitude of problems, including

structural and/or component failure. Many conditions

can be discovered by careful observation. If the

problem is wheel unbalance, in-place balancing can

be done providing there is access to the fan wheel.

Generally, fan vibration and noise is transmitted

to other parts of the building by the ductwork. To

eliminate this undesirable effect, Greenheck has

used a heavy canvas connection between the scroll

and the discharge of the fan. If noise is an issue, we

recommend using heavy canvas connections on the

inlet of the fan. Refer to the Troubleshooting section of

this manual if a problem develops.

4. Air Volume Check and Measurement

Along with the building balance, the unit’s air volume

(cfm) should be measured and compared with its

rated air volume. This unit is flexible for varying air

volume, but the actual air volume should be known for

making final adjustments. The most accurate way to

measure the air volume is by using the pitot traverse

method in the ductwork away from the blower. Other

methods can be used, but should be proven and

accurate. To adjust the air volume, change the fan rpm

or the system losses. See Troubleshooting section in

this guide.

5. Measure Motor Voltage, Amperage

and Fan RPM

All access doors must be installed. Measure and

record the input voltage and motor amperage(s).

To measure the fan RPM, the blower door will need to

be removed. Minimize measurement time because the

motor may over amp with the door removed.

Compare measured amps to the motor nameplate

full load amps and correct if over amping. See the

Troubleshooting section in this guide.

1. Check Voltage

Before starting the unit, compare the supplied voltage

with the unit’s nameplate voltage and the motor

voltage. Units are not provided with thermal overload

protection unless a control center has been ordered

with the unit or the motor has been selected with

thermal overload protection.

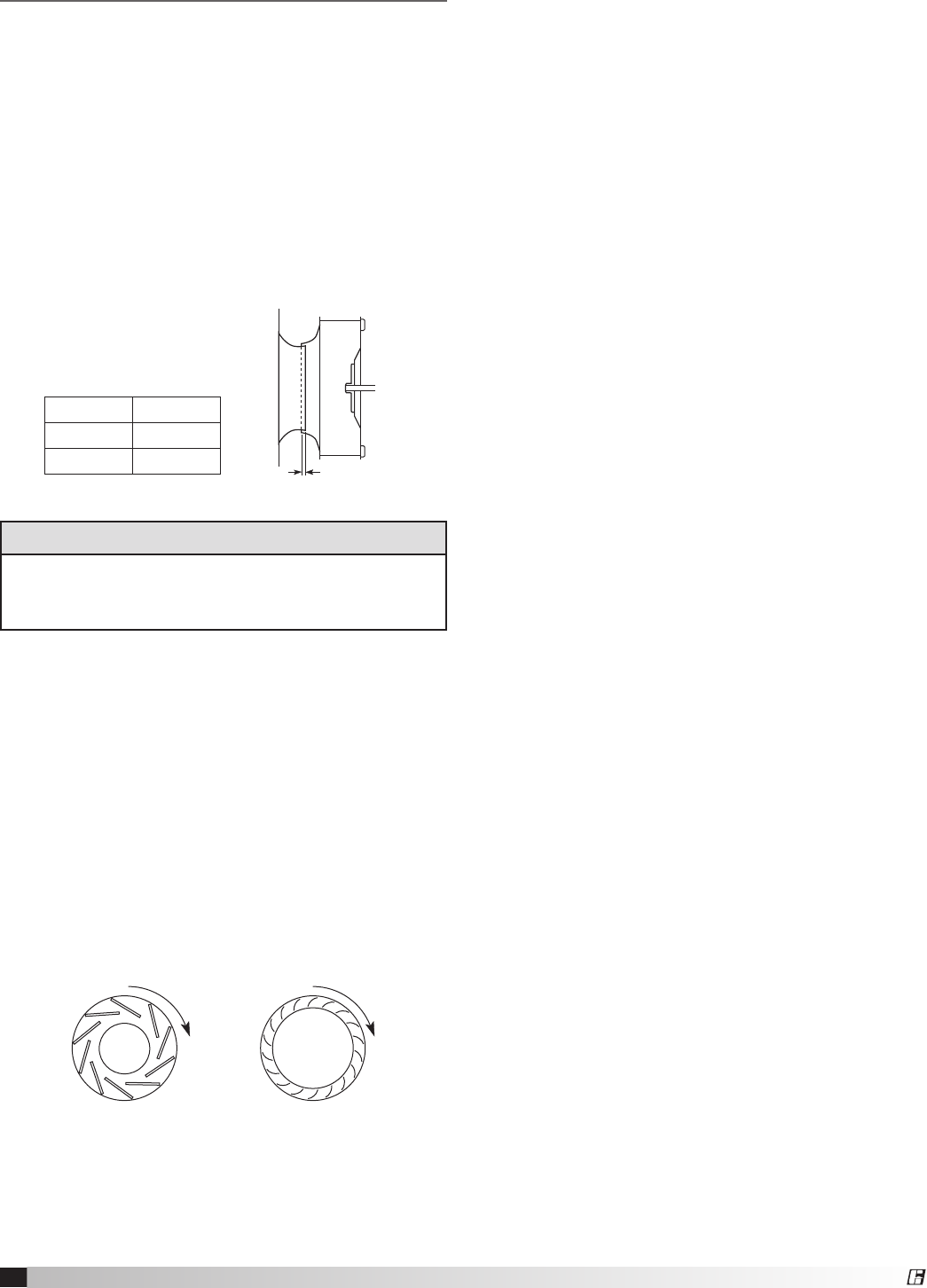

2. Check Blower Rotation

A common problem is wheel rotation in the wrong

direction. For centrifugal fans, incorrect wheel rotation

will provide poor air performance, motor overloading

and possible burnout. Rotation should be checked

while the fan is coasting to a stop. Proper wheel

rotation is shown.

When connecting a 3-phase motor, there is a 50%

chance that the fan will run backwards. Changing

SPECIAL TOOLS REQUIRED

•VoltageMeter

•Tachometer

•AmperageMeter

Backward

Inclined

Airfoil

Forward

Curved

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Backward

Inclined

Airfoil

Forward

Curved

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Proper Wheel Rotation

C

l

o

c

k

w

i

s

e

Belt Span

Deflection =

Belt Span

64

G

CORRECT WRONG WRONG WRONG

Unit Size G

25 - 50 1/4 inch

65 - 85 3/8 inch

Wheel Overlap Dimensions

System Start-Up

For proper unit function and safety, follow everything

in this start-up procedure in the order presented.

This is to be done after the electrical connections are

complete.

PRE-START CHECK LIST

1. Disconnect and lock-out all power switches to fan.

2. Check all fasteners, set screws and locking

collars on the fan, bearings, drive, motor base and

accessories for tightness.

3. Rotate the fan wheel by hand and assure no parts

are rubbing.

4. Check the V-belt drive for proper alignment and

tension.