Maintenance

Maintenance

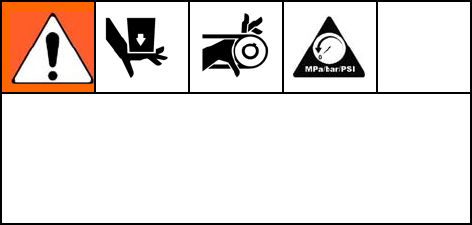

Maintenance and repair of the pump involves

potentially hazardous procedures. Only trained

and qualified personnel who have read and who

understand the instructions in this manual should

maintain or repair this equipment.

Preventive Maintenance Schedule

Check the following items at the intervals listed below,

following all of the safety warnings in this manual.

Every Three Months

Check gauges on pump inlet and outlet and pump

operating speed to confirm operating point.

Every Six Months

• Check bearing temperature and compare with

earlier readings.

• Run an amperage reading to verify that the motor

is running normally.

• Inspect the fan guard and remove any accumulated

debris from under it and around the motor.

• Tighten any fasteners that may be loose.

• Lubricate the motor. See the motor manufacturer’s

instructions.

• Lubricate the pump. See

Pump Bearing Lubrication, page 20, and

Hose Lubrication, page 20.

Flushing

• Flush before changing fluids, before fluid can dry

in the equipment, at the end of the day, before

storing, and before repairing equipment.

• Flush at the lowest pressure possible. Check

connectors for leaks and tighten as necessary.

• Flush with a fluid that is compatible with the fluid

being dispensed and the equipment wetted parts.

Pump Bearing Lubrication

Grease-lubricated pump bearings require an NLGI

Number 2 grease such as Shell Dolium R or

equivalent. Grease the bearings every 24 months,

depending on duty cycle and ambient conditions.

1. Remove the plug (18) from the pump housing

and replace it with a zerk fitting.

2. Use a low pressure grease gun to pump grease

into the zerk fitting. Add grease until it passes

through the outer bearing of the shaft.

3. Remove the zerk fitting and reinstall the plug (18).

Inspect the pump and re-grease the bearings if you

suspect that the original grease was contaminated

by a grease seal failure.

Hose Lubrication

The pump requires lubrication of the hose. The

lubrication provides longer hose life by increasing

cooling and reducing friction between the roller and

the hose. The use of non-standard lubricant can

impact your hose life; always use genuine Graco

hose lube.

Fill your pump to the level indicated in

Lubricate the Pump, page 10.

20 3A1938E