Installation

6 309911C

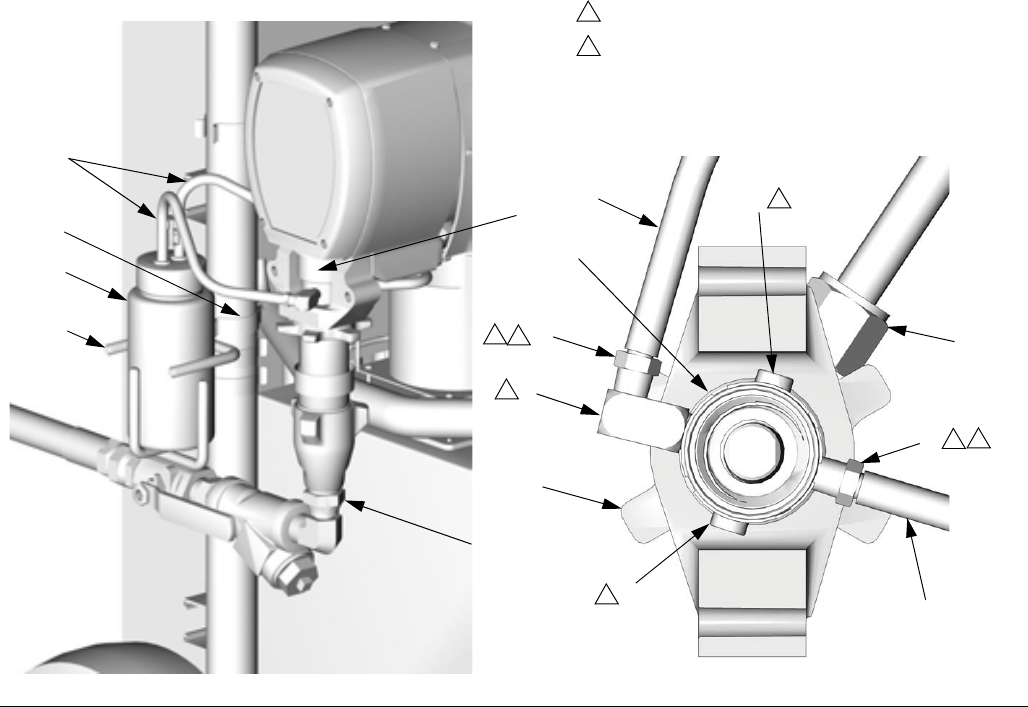

8. Apply thread sealant and screw barbed fitting (2)

into motor side of wet-cup (10). Torque to 10-15 ft-lb

(14-20 N•m). Do not overtighten.

9. Apply thread sealant and screw elbow (8) into

remaining wet-cup port. Torque to 10-15 ft-lb (14-20

N•m). Do not overtighten.

10. Apply thread sealant and screw barbed fitting (2)

into elbow (8). Torque to 10-15 ft-lb (14-20 N•m). Do

not overtighten.

11. Connect component A outlet tube (D) loosely at

pump and at heater. Line up tube, then tighten fit-

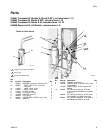

tings securely.

12. Tighten star-shaped locknut (G) by hitting firmly with

a non-sparking hammer.

13. Position holder (4) on Reactor frame upright and

secure with two spring clips (5).

14. Fill reservoir (1) 3/4 full with TSL (6). Place in holder

(4).

15. Apply thin film of TSL to barbed fittings (2). Using

two hands, support tubing (1a) while pushing it

straight onto barbed fittings (2). Do not let tubing

kink or buckle. Secure each tube with a wire tie (7)

between two barbs.

16. Connect swivel elbow (C) to pump fluid inlet.

17. Purge Air and Prime Flush Kit, page 7.

F

IG. 3

TI4331aTI4173a

Top View of Wet-Cup

10

1a

3

D

3

G

2

Torque to 10-15 ft-lb (14-20 N•m). Do not overtighten.

Apply thin film of TSL to barbs.

1

2

1a

2

8

1a

9

C

5

1

4

2

1

1

1

1

1

2