4 307983

Service

Pressure Relief Procedure

WARNING

PRESSURIZED EQUIPMENT HAZARD

The system pressure must be manually relieved to

prevent the system from starting or spraying acci-

dentally. To reduce the risk of an injury from acci-

dental spray from the gun, splashing fluid, or

moving parts, follow the Pressure Relief Proce-

dure whenever you:

D are instructed to relieve the pressure,

D stop spraying,

D check or service any of the system equipment,

D or install or clean the spray nozzle.

1. Shut off the air or hydraulic power supply to the

pump.

2. Close the bleed-type master air valve (required in

air-powered systems).

3. Hold a metal part of the gun firmly to the side of a

grounded metal pail, and trigger the gun to relieve

pressure.

4. Open the drain valve (required in your system),

having a container ready to catch the drainage.

5. Leave the drain valve open until you are ready to

spray again.

If you suspect that the spray nozzle or hose is com-

pletely clogged, or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the nozzle retaining ring or hose end coupling

and relieve pressure gradually, then loosen completely.

Now clear the nozzle or hose.

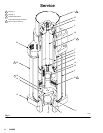

Piston and Intake Valve Adjustment

See Fig. 1. The fluid piston and intake check valves

are factory-set for pumping medium viscosity fluids.

The ball stop pin (18) in the intake valve is in the

lowest set of holes. The piston ball travel is set at

0.204 in. (5.2 mm), measured from the end of the

adjustable plunger rod (23) to the top of the ball (22).

This distance represents four complete turns of the rod

(23) from the top of the ball.

1. If you are pumping heavy viscosity fluid and

erratic pump operation develops, disassemble

the pump as explained on page 5. To increase

the ball travel in the intake valve, move the pin (18)

to the center or upper set of holes. To increase the

ball travel in the piston valve, place the piston in a

vise, loosen the upper cap (27) to relieve tension

on the plunger rod (23), and turn the plunger rod

counterclockwise two complete turns beyond its

factory-set position, or enough to set the total ball

travel to 0.306 in. (7.8 mm).

2. If you are pumping lighter viscosity fluid and

surging develops, disassemble the pump as

explained on page 5. To decrease the ball travel

in the intake valve, place the pin (18) in the lowest

set of holes. To decrease the ball travel in the

piston valve, place the piston in a vise, loosen the

upper cap (27) to relieve tension on the plunger

rod (23), and turn the plunger rod clockwise two

complete turns beyond its factory-set position, or

enough to set the total ball travel to 0.102 in. (2.6

mm).

06081

27

23

18

15

Piston Valve

Ball Travel

Intake Valve

16

22

Fig. 1

Ball Travel