8 306563

Service

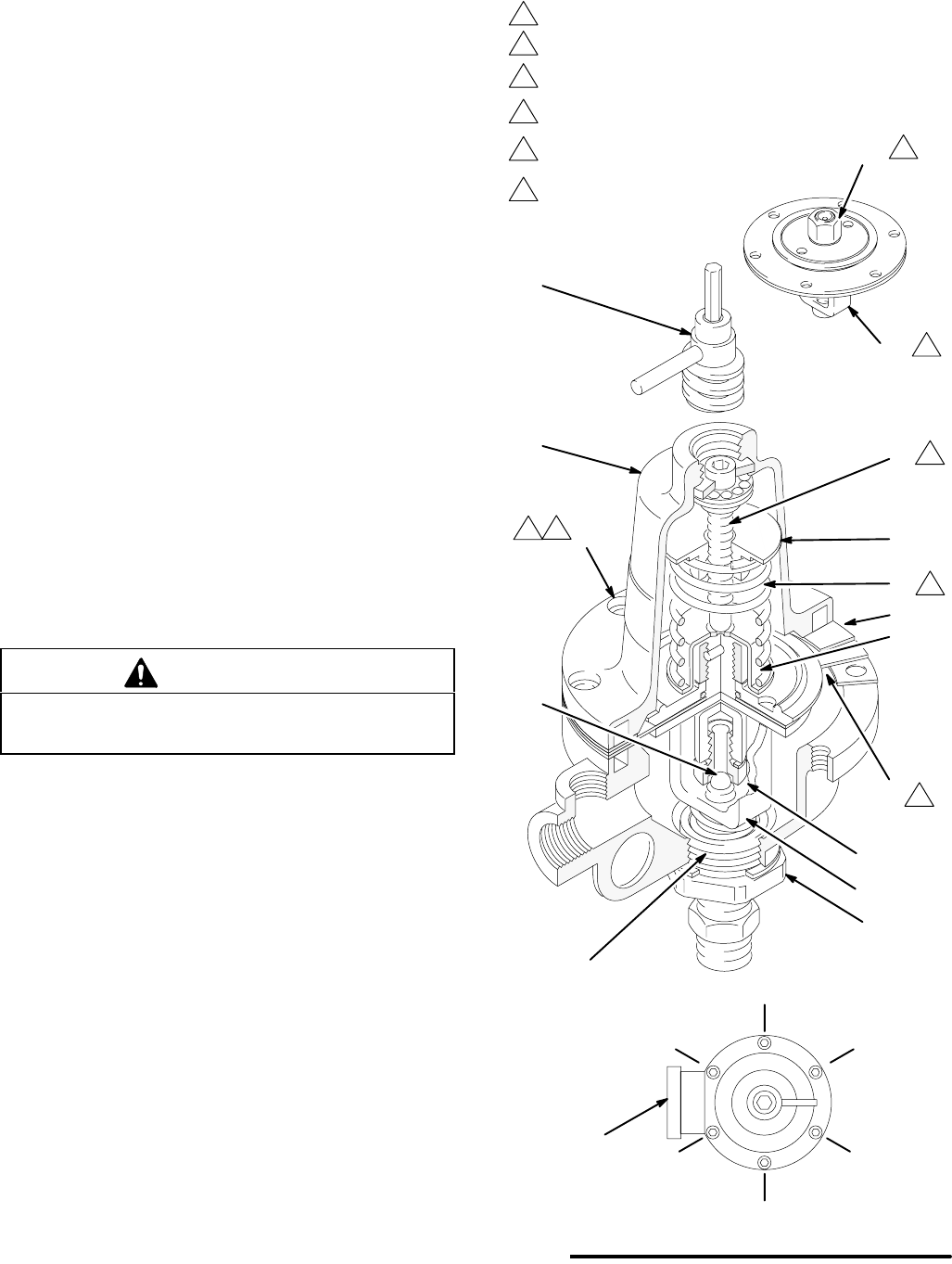

Regulator Disassembly

Shut off pump, close shutoff valve and relieve pressure

in regulator by triggering the spray gun. Remove the

regulator from the system.

1. Using the hex end of key (25), adjust screw (20) all

the way counterclockwise to relieve regulator

spring tension.

2. Remove outlet bushing (15) and counter-balance

spring (29) (Model 204500 only) from the body.

3. Unscrew valve stem (27) from diaphragm hanger

(28) with adjusting key. See Fig. 3.

4. Remove screws (1), regulator cap (17), spring

adjusting screw (20), spring (13), and spring

cap (30) (Model 204500 only).

5. Lift diaphragm (31) and hanger from body. Disas-

semble the hanger and diaphragm only if dam-

aged.

6. Unscrew valve seat (26) from body with a 9/16”

socket wrench. See Fig. 3.

7. Thoroughly inspect all parts and inspect for wear

or damage, replacing as necessary.

CAUTION

Use special care in handling the valve stem and seat

to avoid damaging the hard carbide parts.

Regulator Reassembly

Reassemble regulator in reverse order of Disassem-

bly. When inserting the diaphragm and hanger, be

sure that all surfaces are clean and smooth. Any dirt or

roughness could damage the diaphragm.

Note: Hold hanger (28) and valve stem (27) in place

with a finger so that the valve stem is correctly lined up

with the valve seat (26).

The hanger should be in line with one set of holes and

the nut should be torqued to 20 ft-lb (27 NSm). Turn the

valve stem snugly against the seat and then back off

1/2 turn on model 204500 and 3/4 turn on other mod-

els to set valve clearance. When installing the

cap (17), line up finger of spring adjusting nut (12) with

the groove in the cap (17) . Torque the six screws (1)

evenly to 120–130 in-lb (13.6–14.7 NSm) three times

consecutively, in the order shown in the TOP VIEW, to

compensate for diaphragm relaxation. See Fig. 3.

Note: If further service is needed, see notes on lu-

brication, thread sealant, and torque values in Fig. 4.

03372

03370

03371

Fig. 3

1

3

4

2

1

23

4

5

6

Gauge

25

17

1

1

27

29

15

28

26

31

2

30

13 3

32

12

20

3

28

10

5

5

See TOP VIEW for tightening sequence.

Lubricate with oil.

Lubricate with grease.

4

Torque to 20 ft-lb (27 NSm).

Hanger must be parallel

to diaphragm holes.

TOP VIEW

6

6

Torque to 120–130 in-lb

(13.6–14.7 NSm).