6 306563

Operation

WARNING

To reduce the risk of component rupture, which

can cause a fire or explosion and result in

serious bodily injury, including splashing in the

eyes, never exceed 250 psi (18 bar, 1.8 MPa)

Maximum Inbound Fluid Pressure to this regula-

tor.

CAUTION

Do not pressure test the regulator with air; use

solvent. Air may cause leaks between the fluid seals

and result in fluid leaks during normal operation.

If the rest of the system must be pressure tested

with air, loop past the regulator during the test.

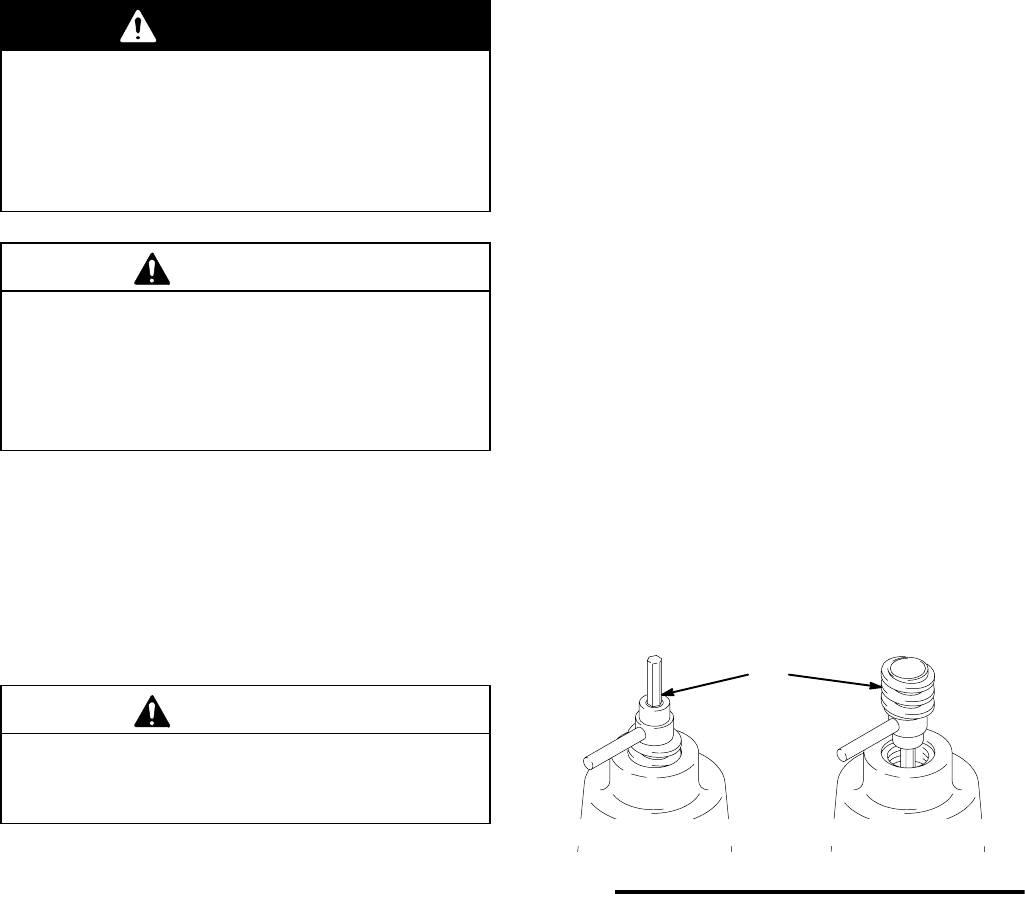

1. Insert hex end of key (25) in adjusting screw (20)

and turn counterclockwise until spring tension is

relieved. See Figs 2 and 3.

2. Start pump and open shutoff valve of outlet (H) to

admit fluid to regulator. Turn key (25) clockwise

until desired fluid pressure shows on gauge.

CAUTION

Do not exceed the Regulated Pressure specification

of your regulator. Pressures higher than specified

can damage the gauge.

Note: When reducing pressure, relieve pressure in gun

and supply line to ensure a correct gauge reading.

CLEANING THE REGULATOR

Note: Flush the regulator every four weeks, or as

necessary for the amount and type of use.

1. Clear regulator of paint or other fluid by blowing

back fluid through the gun and hose.

2. Shut off supply pump and relieve line pressure by

opening back pressure regulator or other by-pass

valve.

3. Open regulator valve by screwing the threaded

portion of key (25) as far as possible into the cap.

See Fig. 2.

4. Loosen air cap ring of spray gun three turns, hold

a rag firmly over the end of the cap and trigger the

gun. Air will force fluid back through the gun, hose

and regulator.

5. After blow-back, remove the adjusting key (25)

Note: Do not use the threaded end of key (25) to

adjust pressure.

6. Flush regulator until clean.

25

Fig. 2

Blow Back Position Regulating Position

03369