12

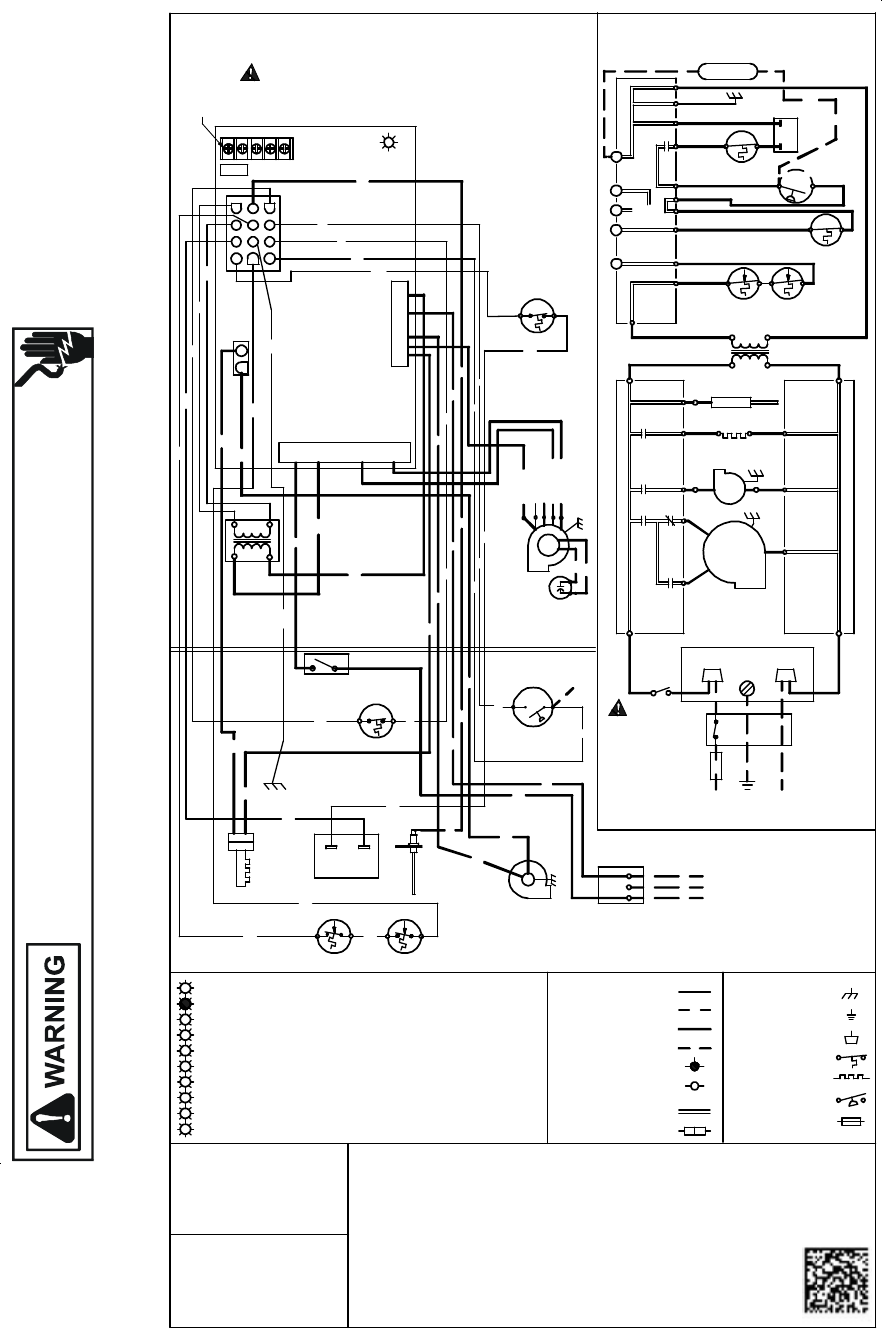

WIRING DIAGRAMS

Wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring.

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS

UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO

DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

GMS8

CAP

BK

(

HI

)

AUX ILI ARY

INTEGRATED

PROPERLY POLARIZED AND GROUNDED.

SERVICING.WIRING TO UNIT MUST BE

WARNING:DISCONNECT POWER BEFORE

FUSE

GC

6

3

9

12

W

YRR

5

4

12

8

7

11

10

OR

LED

DIAGNOSTIC

LINE-H XFMR-H HEAT- H COOL-H

CONTROL MODULE

BK

115 VAC HOT AND PARK TERMINALS

2

1

GR

PU

XFMR

BK

BK

BK

115V

24V

115 VAC NEUTRAL

BR

LIMITS

WH

WH (N)

RD (LOW)

OR (MED LOW)

BL (MED)

CICULATOR BLOWER

24V THERMOSTAT CONNECTIONS

RO2 (11)

LIMIT

GND (8)

HUM IDIFI ER

XFMR (6)

GND

G

C

W

Y

TO

MICRO

R

MV (12)

MVC (9)

AUXIL IARY

LIMIT CONTROL S

PS (10)

PSO (4)

HLI (7)

HLO (1)

CONTROL MODULE

INTEGRATED

NO

SWITCH

PRESSURE

ID BLOWER

VA LVE

M1

GAS

C2

C

AUTO RESET

PRIMARY

MANUAL RESET ROLLOUT

LIMIT CONTROL(S)

115 VAC

FLAME SENSOR

FP (2)

XFMR-H

XFMR (3)

RO1 (5)

24 VAC

HOT SURFACE

IGNITER

INTEGRATED CONTROL MODULE

BR

BR

COOL-H

IGN

IND

ID

BLWR

CIRCULATOR

HEAT-H

C

O

O

L

H

E

A

T

BLWR

TRANSFORMER

40 VA

CONTROL

XFMR-N

INTEGRATED CONTROL MODULE

CI R-N

0140F00119-C

5. UNIT MUST BE PERMANENTLY GROUNDED AND CONFORM TO N.E.C. AND LOCAL CODES.

ON SOME MODELS

HUMIDIFIER

24 VAC

INDUCED DRAFT

C. USE COPPER CONDUCTORS ONLY.

BLOWER COMPARTMENT

BURNER COMPARTMENT

REPLACED, IT MUST BE REPLACED WITH WIRING MATERIAL HAVING A TEMPERATURE

3. IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE FURNACE MUST BE

CORRECT COOLING CFM. (SEE SPEC SHEET FOR AIR FLOW CHART)

REQUIREMENTS SO AS TO PROVIDE THE CORRECT HEATING TEMPERATURE RISE AND THE

4. BLOWER SPEEDS MUST BE ADJUSTED BY INSTALLER TO MATCH THE INSTALLATION

INTEGRATED CONTROL

INTERNAL TO

2. MANUFACTURER'S SPECIFIED REPLACEMENT PARTS MUST BE USED WHEN SERVICING.

1. SET HEAT ANTICIPATOR ON ROOM THERMOSTAT AT 0.7 AMPS.

BLOWER

GAS VALVE

PRIMARY LIMIT

BK

GR

WH

IGNITER

SURFACE

HO T

M1

PU

WH

RD

WH

15 PIN PLUG

C

NO

SWITCH

PRESSURE

BR

C2

SENSOR

FLAME

BK

W

H

ROLLOUT LIMITS

RAPID FLASHES = REVERSED 115 VAC POLARITY/VERIFY GND

1 FLASH = SYSTEM LOCKOUT (RETRIES/RECYCLES EXCEEDED)

7 FLASHES = LOW FLAME SIGNAL

5 FLASHES = FLAME SENSE WITHOUT GAS VALVE

4 FLASHES = OPEN HIGH LIMIT

3 FLASHES = PRESSURE SWITCH STUCK OPEN

2 FLASHES = PRESSURE SWITCH STUCK CLOSED

STEADY ON = NORMAL OPERATION

OFF = CONTROL FAILURE

5

0

1

2

3

4

PU

6 FLASHES = OPEN ROLLOUT

COLOR CODES:

PU PURPLE

OR ORANGE

YL YELLOW

6

7

C

BK BLACK

GR GREEN

BR BROWN

PK PINK

RD RED

GY GRAY

BL BLUE

WH WHITE

PU

RATING OF AT LEAST 105

NOTES:

TO 115VAC/ 1

Ø /60 HZ POWER SUPPLY WITH

OVERCURRENT PROTECTION DEVICE

JUNCTION BOX

MUST BE

WARNING:

SWITCH

WIRING TO UNIT

BEFORE SERVICING.

DISCONNECT POWER

LINE-H

DOOR

AND GROUNDED.

POLARIZED

PROPERLY

LGND

LINE-N

DISCONNECT

N

SWITCH (TEMP.)

FIELD SPLICE

SWITCH (PRESS.)

PROT. DEVICE

OVERCURRENT

EQUIPMENT GND

TERMINAL

JUNCTION

HI VOLTAGE FIELD

HI VOLTAGE (115V)

LOW VOLTAGE FIELD

LOW VOLTAGE (24V)

PLUG CONNECTION

IGNITER

FIELD GND

IND-N

IGN-N

JUNCTION

BOX

OVERCURRENT PROTECTION

POWER SUPPLY WITH

TO 115 VAC/ 1/60HZ

GND

LINE-N

LINE H

DEVICE

DOOR SWITCH

WH

BK

SWITCH LOCATED IN BLOWER

COMPARTMENT ON SOME MODELS

RD

RD

RD

BL

YL

YL

RD

BL

BL

PU

YL

YL

BR

OR

OROR

YL

YL

RD RD

WHWH

WH

YL

OR

BK

YL

BR

WH

(SINGLE CONTROL ON SOME MODELS)

(SINGLE CONTROL ON SOME MODELS)

24 VAC

HUMIDIFIER