14

2 Installation

2.7 Cold water inlet controls and pipework

Connect both parts of the water control pack.

When installing the valves, make sure they are aligned in

such a way that the 15mm connection of the expansion relief

valve can be connected to the tundish.

Install the assembled water control pack in the cold water

supply at an appropriate place next to the solar cylinder.

Make sure there is sufcient space for maintenance and the

connection of the discharge pipe from the expansion relief

valve.

Install the drain valve in the cold water supply at the lowest

point between the solar cylinder and the water control pack.

We recommend applying a hose, which reaches about 1m

under the base of the cylinder, to the outlet of the drain valve.

IMPORTANT: Risk of bursts for the solar cylinder! No stop

valve may be installed between the cold water control pack

and the cylinder.

Install the water pack so that a discharge pipe of the

expansion relief valve can be tted with constant outward

slope which can end at a safe, visible point where there is no

risk of freezing.

IMPORTANT: Risk of the solar cylinder bursting due to

overpressure! The outlet of the expansion relief valve must

not be covered or closed.

Test the expansion relief valve regularly to avoid calcication.

To ensure an optimum performance of the solar cylinder, in

particularly buildings in which a pressure controlled cold water

is used, copper pipes with a diameter of at least 22mm should

be used for the pipe from the main stop valve of the building

to the solar cylinder.

If the discharge pipes are all together, the expansion relief

valve may not be installed more than 500 mm away from the

temperature and pressure relief valve.

The Flurocyl solar cylinder is supplied with an external hot

water expansion vessel (DW EV).

Connect this expansion vessel to the installed water control

pack as follows:

Screw the expansion vessel directly onto the water control

pack, via the connection intended for this purpose or

Connect the expansion vessel to the water control pack with a

copper pipe or an appropriate hose. Make sure the expansion

vessel is supported sufciently.

Use the supplied mounting bracket if the expansion vessel is

to be mounted on the wall.

Connect thermostatic mixing valve cold supply to the pressure

controlled cold water connection of the water control pack (if

convenient).

NOTE: In areas with high water pressure (4 bar or more), a

bath or shower mixer valve could also be connected to the

pressure-controlled cold water connection of the water control

pack. This is to ensure the pressure of the hot and cold water

supply to the mixer valve is about the same. Any second

cold water supply connection should be installed between

the water control pack and the solar cylinder by means of a

T-piece.

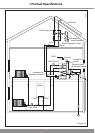

COLD

WATER

SUPPLY

PRESSURE LIMITING

VALVE WITH LINER

STRAINER

BALANCED

PRESSURE

COLD WATER

CONNECTION

HOT WATER

EXPANSION

VESSEL

CONNECTION

EXPANSION

RELIEF VALVE

FLUROCYL

CONNECTION

LEGIONELLA

LOOP

CONNECTION

Diagram 2.4

14187

2.8 Discharge pipework

The outlet connections of both the temperature / pressure

relief valve and expansion relief valve should be connected in

15mm copper pipe to the tundish supplied. The tundish should

be installed vertically, as close to the Flurocyl as possible and

within 500mm of the temperature and pressure relief outlet. It

must be positioned away from any electrical components and

installed in the same space as the Flurocyl cylinder, so that

it is visible to the user. The D1 discharge pipe from the T&P

Valve/Expansion valve can be teed together upstream of the

tundish.

The discharge pipework must be installed using minimum

22mm copper pipework from the 22mm connection on the

tundish to a safe and visible discharge point.

There must be a vertical section of pipe at least 300mm

long, below the tundish before any bends or elbows in

the pipework. Increase the diameter of the pipework if the

total resistance of the discharge pipework exceeds the

gures shown in table 2.2. The installation of the discharge

pipework must be in accordance with G3 refer to Statutory

Requirements.