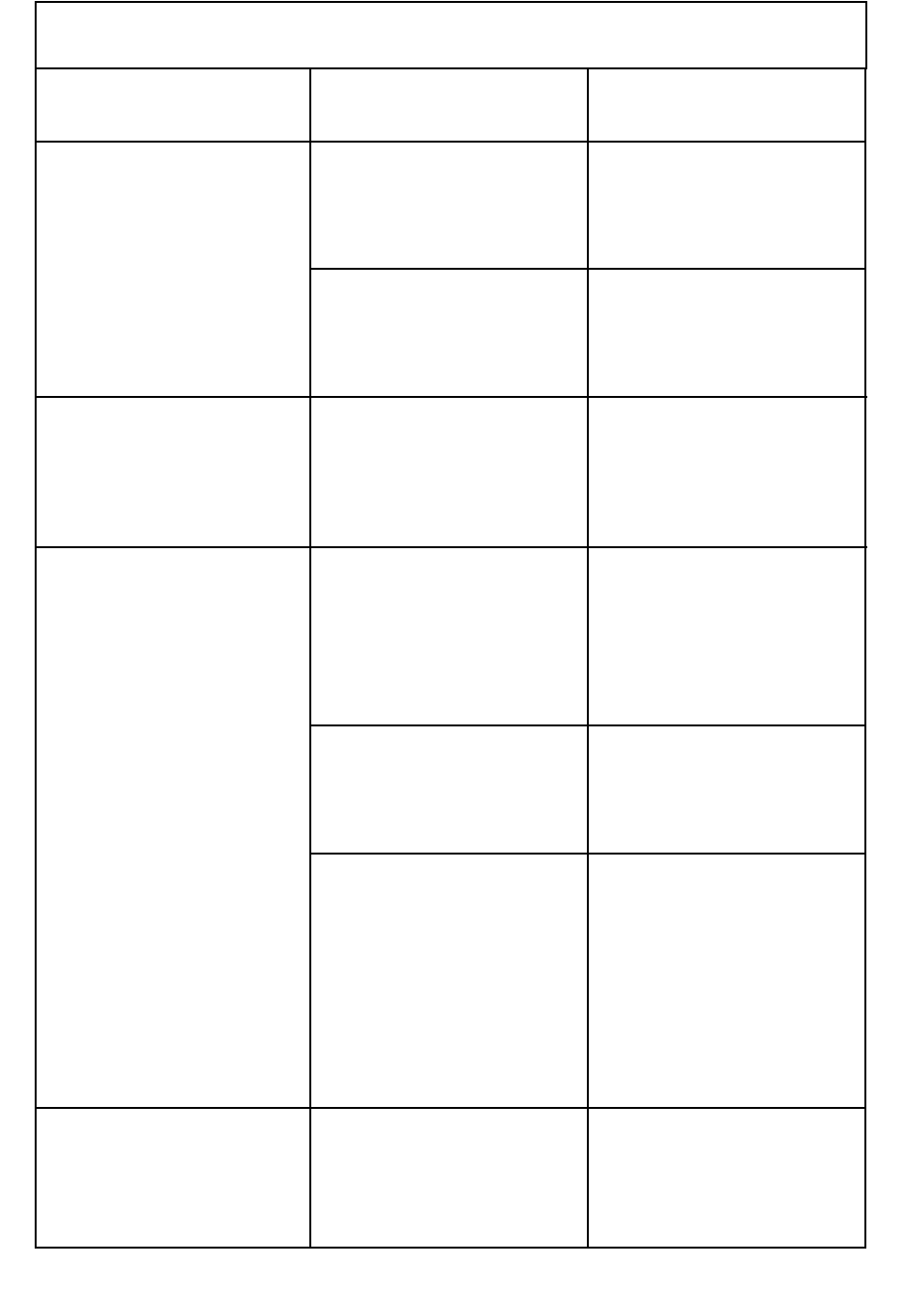

17

REMEDIES

Install new membrane ele-

ment(s). See Spare Parts List

(Section 2.20).

Check the flow rate manually

with a stop watch and a cali-

brated container.

Flush and/or clean machine.

Replace the O-rings, check

the sealing surfaces on the

O-ring groove and end caps.

Replace damaged parts.

Replace with new membrane

elements. See Spare Parts

List (Section 2.20).

Calibrate the meter with a DS

standard solution or check the

readings with another conduc-

tivity meter. Replace or clean

the probe. Check the connec-

tions between the probe and

monitor. Refer to Section

2.16.2 (Deluxe Model).

Ensure machine is

plugged in.

POSSIBLE CAUSES

Useful life of membrane

element(s) expired

Inaccurate permeate flow meter

(DLX only)

Dirty or fouled membrane

element (s)

O-rings on membrane ele-

ment(s) unseated or

damaged parts

Useful life of membrane ele-

ment(s) expired

Change in incoming

water quality

No power to machine

PROBLEM

Low permeate production

(continued)

Low concentrate flow with

normal or high operating

pressure

Declining rejection

(high permeate

conductivity)

ON/OFF switch ON:

machine not running

TROUBLESHOOTING GUIDE