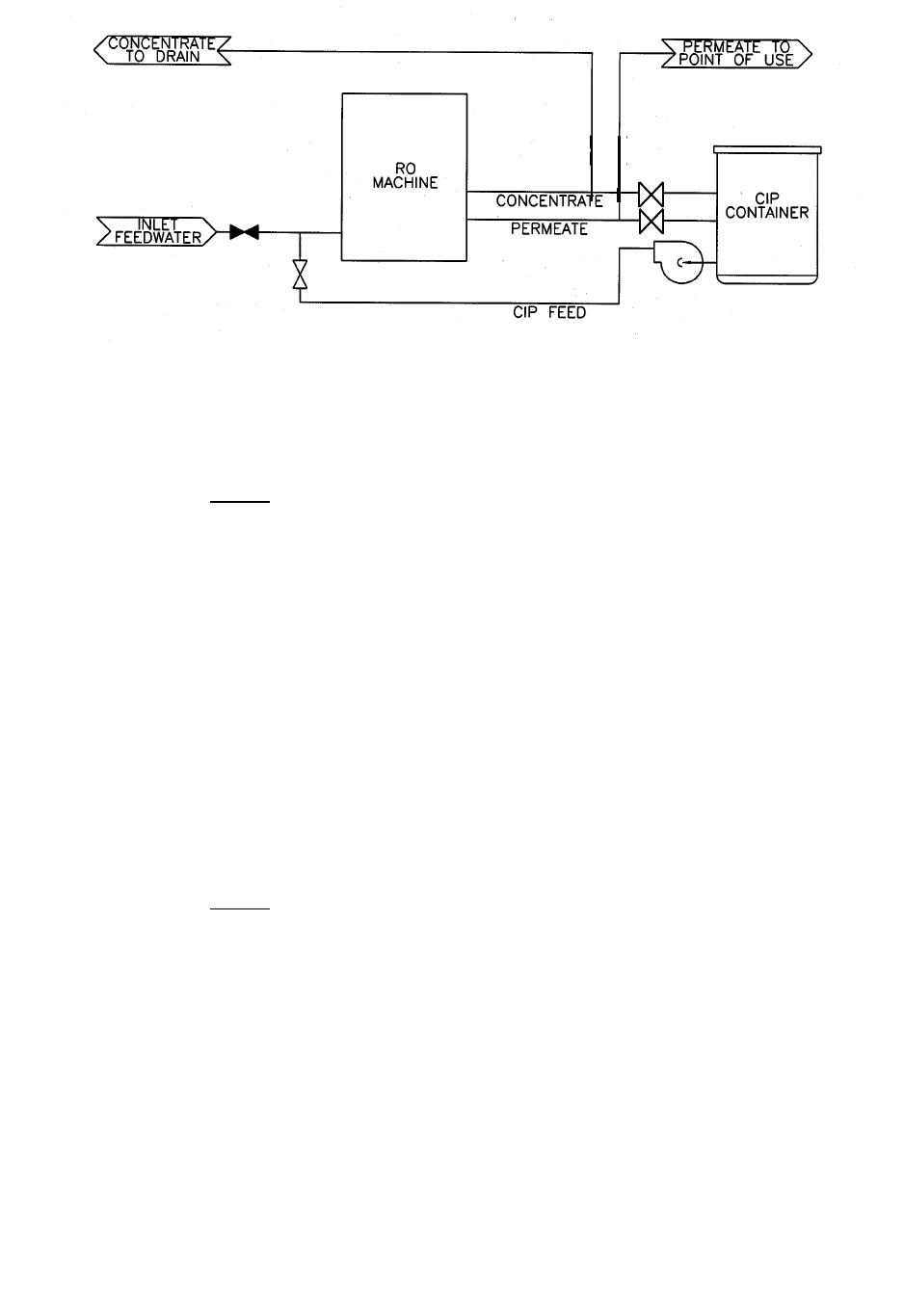

Figure 2.2

E2/EZ2-Series

Closed Loop Membrane

Element Cleaning

NOTE

: This clean container will be referred to as the Clean-In-Place (CIP)

container.

4. Disconnect and route the inlet, permeate, concentrate lines from their service

locations to the CIP container (Figure 2.2 E2/EZ2-Series Closed Loop Membrane

Element Cleaning.

5. Connect the CIP feed line to the E2/EZ2-Series machine inlet feed water port

(Figure 2.2, E2/EZ2-Series Closed Loop Membrane Element Cleaning).

6. Mix the appropriate cleaning compound in the 5 gallons of permeate water, in the

CIP container, according to the cleaning label instructions.

7. Turn machine ON and allow machine to recirculate the cleaning solution for

10 - 15 minutes.

NOTE

: The incoming feed pressure should be 30 psi (2.1 bar).

As machine starts up it will achieve prime and begin to draw solution into the

machine and circulate the solution back into the CIP container.

If the machine makes noise or primary pressure does not climb to normal operat-

ing pressure (Table 2.3, E2/EZ2-Series Primary Pressure Range) turn machine

OFF. Refer to Troubleshooting (Section 1.18). Once pressure range is corrected,

continue start-up procedure.

As the machine runs normally check CIP tank to ensure that the CIP inlet line to

the machine is submerged in the cleaning solution, so the pump prime will not be

lost.

11