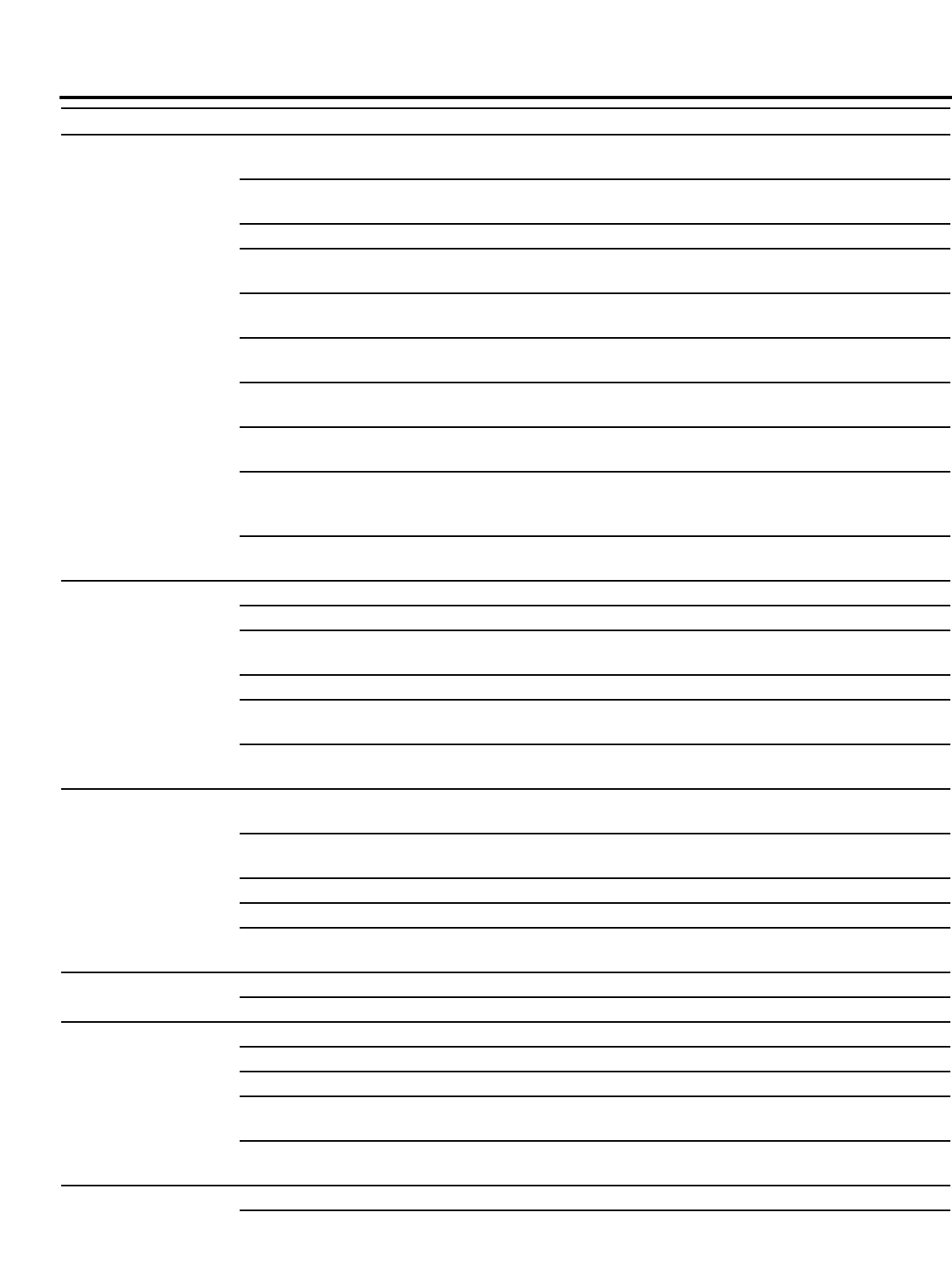

Problem Possible Causes What To Do

Run out of soft water Incorrect injector • With water pressure > 70 psi, use 4 bump injectors

between regenerations (WS15X10059).

Improper regeneration • Repeat regeneration, making certain correct salt dosage is

used.

Fouled resin bed • Use resin cleaner.

Incorrect salt dose and capacity setting • Set Salt per Regen and Capacity setting to proper level. Refer to

the Programming the Control sections.

Incorrect hardness • Set to correct hardness. Refer to the Programming the

Control sections.

Water hardness has increased • Set to new value. Refer to the Programming the Control

sections.

Restricted meter turbine rotation due • Remove bypass, free up turbine and flush with clean

to foreign material in meter housing water. Turbine should spin freely—if not, replace meter.

Water usage below 1/5 gallon • Repair leaky plumbing and/or fixtures.

per minute

Brine draw value from Advanced • Set correct brine draw value.

Programming Parameters table is

incorrect

Incorrect salt type or use of grid plate • Do not use block salt or grid plate (salt shelf) in brine tank.

(salt shelf)

Control does not draw Low water pressure • Increase water pressure (20 psi at conditioner).

brine

Restricted drain line • Remove obstruction.

Injector or injector screen is plugged • Clean injector and screen. Refer to the Cleaning the Injector and

Screen section.

Injector defective • Replace injector and cap.

Valve disc 3 and/or 5 not closed • Manually operate cam gear to flush out foreign matter holding

disc open. Replace if needed.

Air check valve prematurely closed • Briefly put control into brine refill status. Refer to the Manual

Regeneration section. Repair air check valve if needed.

Brine tank overflow Brine valve disc 1 held open • Manually operate cam gear to flush out foreign matter holding

disc open.

Valve disc 2 not closed during brine • Manually operate cam gear to flush out foreign matter holding

draw, causing brine refill disc open.

Air leak in brine line to air check • Check all connections in brine line for leaks.

Salt setting too high • Set in new values. Refer to Advanced Programming section.

Float assembly malfunctions • Inspect float assembly in brine well for proper operation.

It must be able to move freely.

Intermittent or irregular Low water pressure • Increase water pressure (20 psi at conditioner).

brine draw

Defective injector • Replace both injector and injector cap.

No conditioned water Unit did not regenerate • Check for power.

after regeneration

No salt in brine tank • Add salt to brine tank.

Plugged injector • Remove injector and flush it and injector screen.

Air check valve closed prematurely • Put control momentarily into REFILL to free air check. Replace

or repair air check as needed.

Incorrect salt type or use of grid plate • Do not use block salt or grid plate (salt shelf) in brine tank.

(salt shelf) in brine tank

Control backwashes at Incorrect backwash controller • Replace with correct size controller.

excessively low or high

Foreign matter affecting controller • Remove and clean controller.

rate

operation

26

Advanced troubleshooting.