• R-410A pressure is approximately 60% higher than R-22 pressure.

• R-410A cylinders must not be allowed to exceed 125 F, they may leak or rupture.

• R-410A must never be pressurized with a mixture of air, it may become

ammable.

• Servicing equipment and components must be specically designed for use with R-410A and

dedicated to prevent contamination.

• Manifold sets must be equipped with gauges capable of reading 750 psig (high side) and 200

psig (low side), with a 500-psig low-side retard.

• Gauge hoses must have a minimum 750-psig service pressure rating

• Recovery cylinders must have a minimum service pressure rating of 400 psig, (DOT 4BA400

and DOT BW400 approved cylinders).

• POE (Polyol-Ester) lubricants must be used with R-410A equipment.

• To prevent moisture absorption and lubricant contamination, do not leave the refrigeration

system open to the atmosphere longer than 1 hour.

• Weigh-in the refrigerant charge into the high side of the system.

• Introduce liquid refrigerant charge into the high side of the system.

• For low side pressure charging of R-410A, use a charging adaptor.

• Use Friedrich approved R-410A lter dryers only.

The following is a list of important considerations when working with R-410A equipment

R-410A SEALED SYSTEM REPAIR CONSIDERATIONS

Do not puncture, heat, expose to ame or incinerate.

Only certied refrigeration technicians should

service this equipment.

R410A systems operate at higher pressures than

R22 equipment. Appropriate safe service and

handling practicces must be used.

Only use gauge sets designed for use with R410A.

Do not use standard R22 gauge sets.

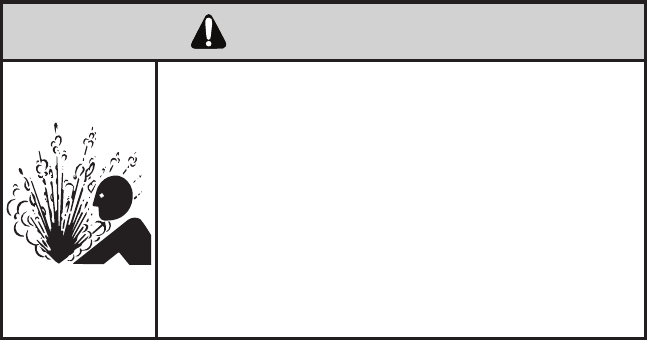

WARNING

Refrigeration system under high pressure

16