Page 11

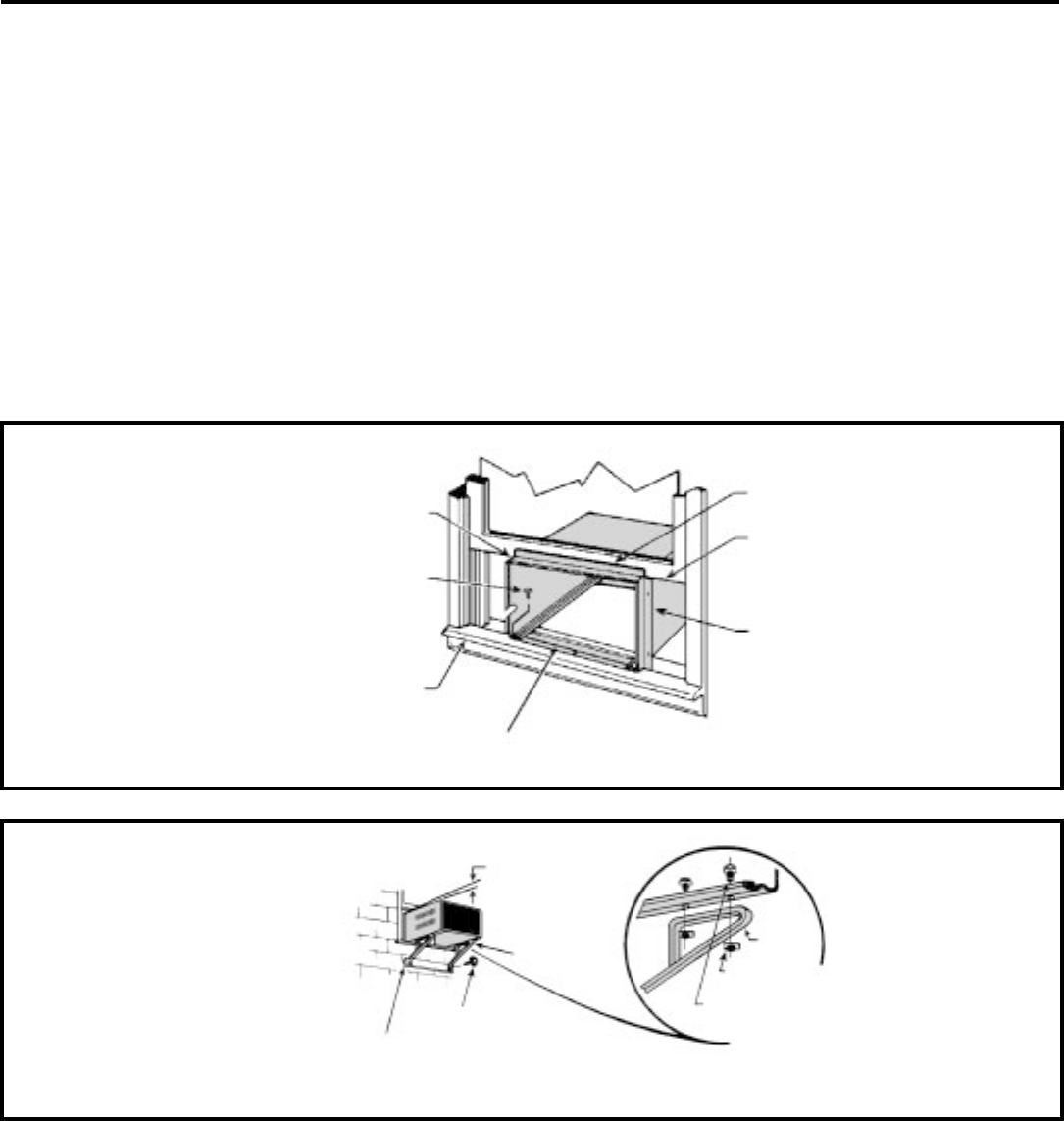

A 1" x 4" or 2" x 4" SPACER SHOULD BE USED BETWEEN THE WALL AND THE SUPPORT BRACKETS WHEN

INSTALLED ON ALUMINUM OR VINYL SIDING). Drill 5/32" (4 mm) dia. pilot holes, and secure the brackets to the wall

with two (2) #12A x 2" long screws (Item #4). Adjust the support brackets to provide an approximate 3/8" (10 mm) down

slope towards the outside for drainage. Tighten all screws. (See Figure E).

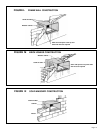

FIGURE D

FIGURE E

STEP 3. OUTSIDE SUPPORT MOUNTING: Assemble the support brackets (Item #1) to the bottom rails of the cabinet

with four (4) 10-24 1" long screws (Item #2) and four (4) 10–24 flat nuts (Item #3). Adjust the support brackets to

bring the bottom pads in contact with the wall surface. (See Figure E.)

SECTION V — SHELL INSTALLATION

(A) SASH WINDOW INSTALLATIONS

SHELL (CABINET) INSTALLATION – STANDARD SASH WINDOWS

STEP 1. Check the window sill and frame to be sure they are in good condition and firmly anchored to the wall. Repair if

necessary.

STEP 2. CABINET MOUNTING: Raise the lower window sash 1/4" more than the height of the cabinet. Carefully slide

the cabinet through the open window until the sill plate channel rests behind the window sill and the top support

angle rests against the window (See Figure D). Center the cabinet side to side and drill three (3) 5/32" dia. pilot

holes into the window sill using the holes in the cabinet sill plate as a guide. Install three (3) #12A x 2" long screws

(Item #4) (See Figure D).

Center cabinet side to

side in window

Drill 3 5/32" pilot holes and install 3

#12A x 2" long screws (Item #4)

Window sill

Locate the sill plate guide channel

just back of the window sill.

Top Support Angle

Pull window sash down behind

the top support angle

Side Support Angle

A 1" x 4" or 2" x 4" spacer should be used between the

wall and bracket when installed on aluminum, asbestos

or vinyl siding.

3/8" (10 mm)

Down slope

Support

Bracket

(Item #1)

#12A x 2" Screw (Item #4)

Support

Bracket

10 - 24 Flat Weldnut (Item #3)

10 - 24 x 1" Hex Head Screw (Item #2)