10

www.retroaire.com

The Right Fit For Comfort

Hydronic Only: Remove the 2-position connector as-

sembly from kit bag supplied with unit (this will have 2

yellow wires attached). Connect this 2-position connec-

tor to the 2-position connection located on the bottom

of the control box panel.

To Connect Aquastat:

A. Remove the black jumper wire located on the

bottom panel of the control box (this is also ter-

minated with a 2-position connector).

B. Cut the jumper wire in the middle and splice the

aquastat to the jumper.

C. Place the connecter back into original location.

Refer to wire diagram on the unit for details.

8. Connect line cord.

9. See Final Inspection and Startup on page 20.

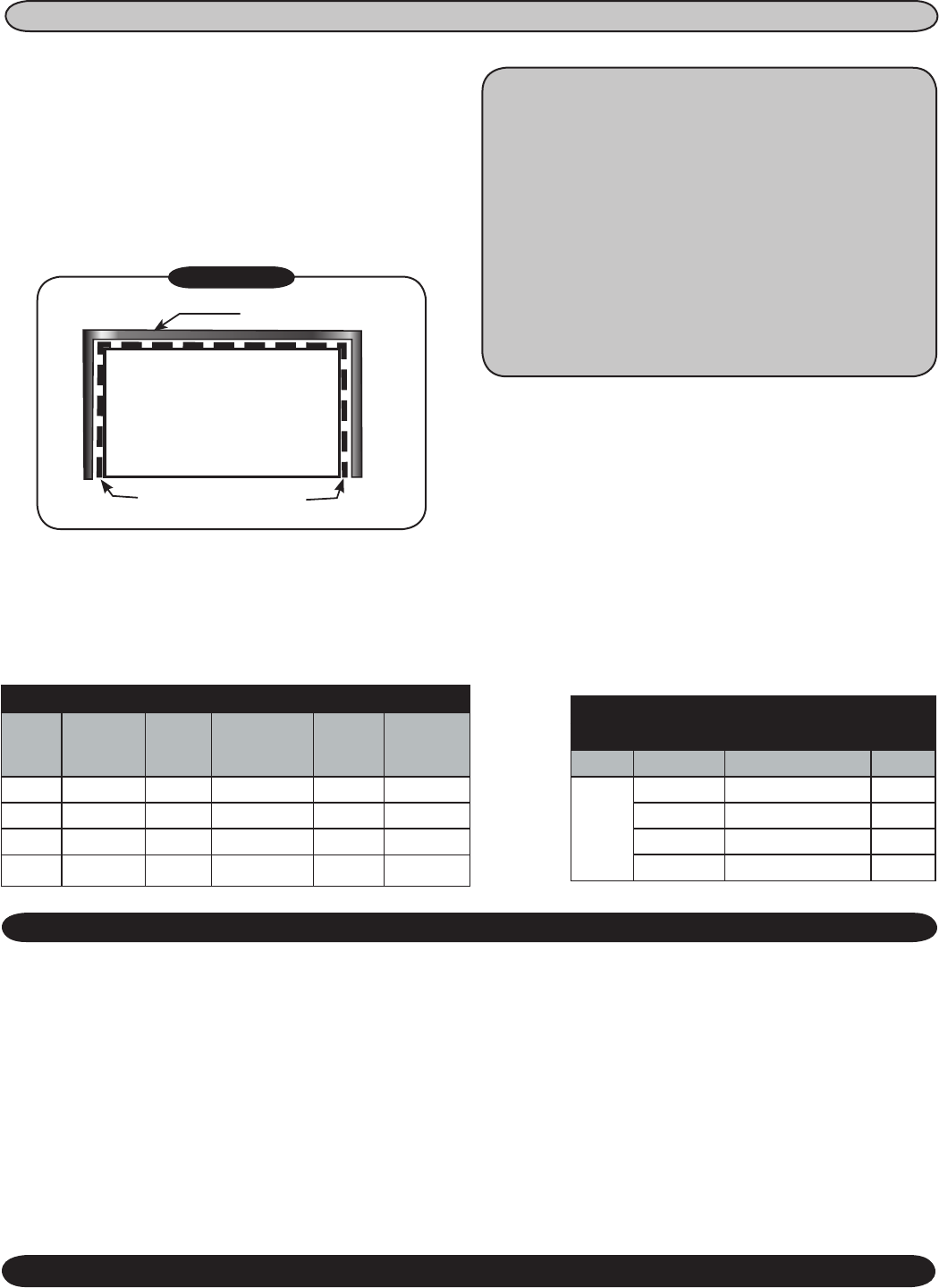

6. 1” x 1” Open cell foam strips are provided to prevent

outside air from entering around the chassis to the room

from the sides and top of the cabinet. Install between

wall sleeve and cooling chassis. It is imperative to have

a solid air seal between wall sleeve and chassis. Failure

to do so will result in air leakage from outdoor to indoor

causing system problems i.e. coils freezing, short cy-

cling, and constant running of unit. If installer is in need

of more foam than supplied in kit, consult factory.

RC/RH 20 PERFORMANCE DATA*

Unit

Size

Cooling

Btuh

EERs

Heat Pump

Btuh

COP

Fresh Air

CFM

9 9,500 10 8500 2.8 40/35

12 11,900 10 11400 2.9 40/35

15 14,700 9.2 13800 2.8 40/35

18 16,900 9.1 N/A N/A

40/35

RC/RH20 Hydronic Heat *

Performance 104-101 (Single Row Coil)

GPM EWT (°F) Capacities Btuh P.D.

3.0

180°F Hi 16,400 4.4

180°F Lo 15,400 4.4

140°F Hi 10,300 4.6

140°F Lo 9,700 4.6

RC/RH20 INSTALLATION INSTRUCTIONS (Continued)

*Refer to the charts on page 23 for electrical and optional electric heat specifi cations.

7. Once confi dent that all seals are the correct size and in

the proper location and the correct baffl es are attached

to the condenser coil in the proper orientation, slide

unit into fi nal position and tighten any tie down bolts or

screws as necessary.

Figure D4

Front View

Cooling Chassis

Wall Sleeve

1x1 Foam Tape