Many compressor failures are caused by the following

conditions:

1. Improper air fl ow over the evaporator.

2. Overcharged refrigerant system causing liquid to be

returned to the compressor.

3. Restricted refrigerant system.

4. Lack of lubrication.

5. Liquid refrigerant returning to compressor causing oil

to be washed out of bearings.

6. Noncondensables such as air and moisture in

the system. Moisture is extremely destructive to a

refrigerant system.

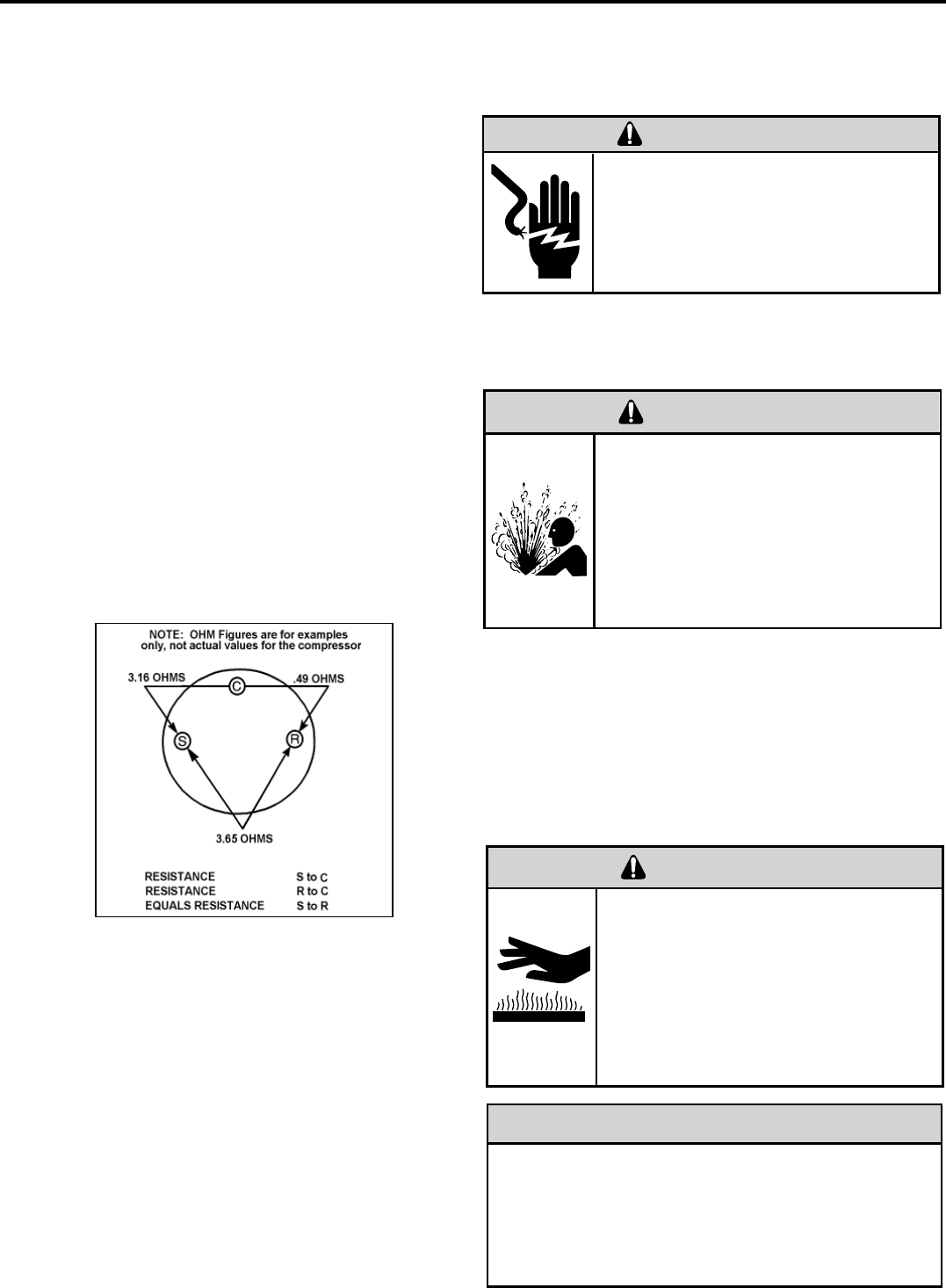

Single Phase Resistance Test

Remove the leads from the compressor terminals and set

the ohmmeter on the lowest scale (R x 1).

Touch the leads of the ohmmeter from terminals common

to start (“C” to “S”). Next, touch the leads of the ohmmeter

from terminals common to run (“C” to “R”).

Add values “C” to “S” and “C” to “R” together and

check resistance from start to run terminals (“S” to “R”).

Resistance “S” to “R” should equal the total of “C” to “S”

and “C” to “R.”

In a single phase PSC compressor motor, the highest

value will be from the start to the run connections (“S” to

“R”). The next highest resistance is from the start to the

common connections (“S” to “C”). The lowest resistance

is from the run to common. (“C” to “R”) Before replacing a

compressor, check to be sure it is defective.

Check the complete electrical system to the compressor

and compressor internal electrical system, check to be

certain that compressor is not out on internal overload.

Complete evaluation of the system must be made

when ever you suspect the compressor is defective.

If the compressor has been operating for sometime, a

careful examination must be made to determine why the

compressor failed.

19

Recommended procedure for compressor

replacement

1. Be certain to perform all necessary electrical and

refrigeration tests to be sure the compressor is

actually defective before replacing.

2. Recover all refrigerant from the system though

the process tubes. PROPER HANDLING OF

RECOVERED REFRIGERANT ACCORDING TO

EPA REGULATIONS IS REQUIRED. Do not use

gauge manifold for this purpose if there has been

a burnout. You will contaminate your manifold and

hoses. Use a Schrader valve adapter and copper

tubing for burnout failures.

Unplug and/or disconnect all electrical power

to the unit before performing inspections,

maintenances or service.

Failure to do so could result in electric shock,

serious injury or death.

WARNING

RISK OF ELECTRIC SHOCK

Sealed Refrigeration System contains refrigerant

and oil under high pressure.

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with refrigerants.

Failure to follow these procedures could

result in serious injury or death.

WARNING

HIGH PRESSURE HAZARD

Extreme care, proper judgment and all safety

procedures must be followed when testing,

troubleshooting, handling or working around

unit while in operation with high temperature

components. Wear protective safety aids

such as: gloves, clothing etc.

Failure to do so could result in serious burn

injury.

WARNING

HIGH TEMPERATURES

The use of a torch requires extreme care and proper

judgment. Follow all safety recommended precautions

and protect surrounding areas with fi re proof materials.

Have a fi re extinguisher readily available. Failure to follow

this notice could result in moderate to serious property

damage.

NOTICE

FIRE HAZARD

COMPRESSOR REPLACEMENT