14

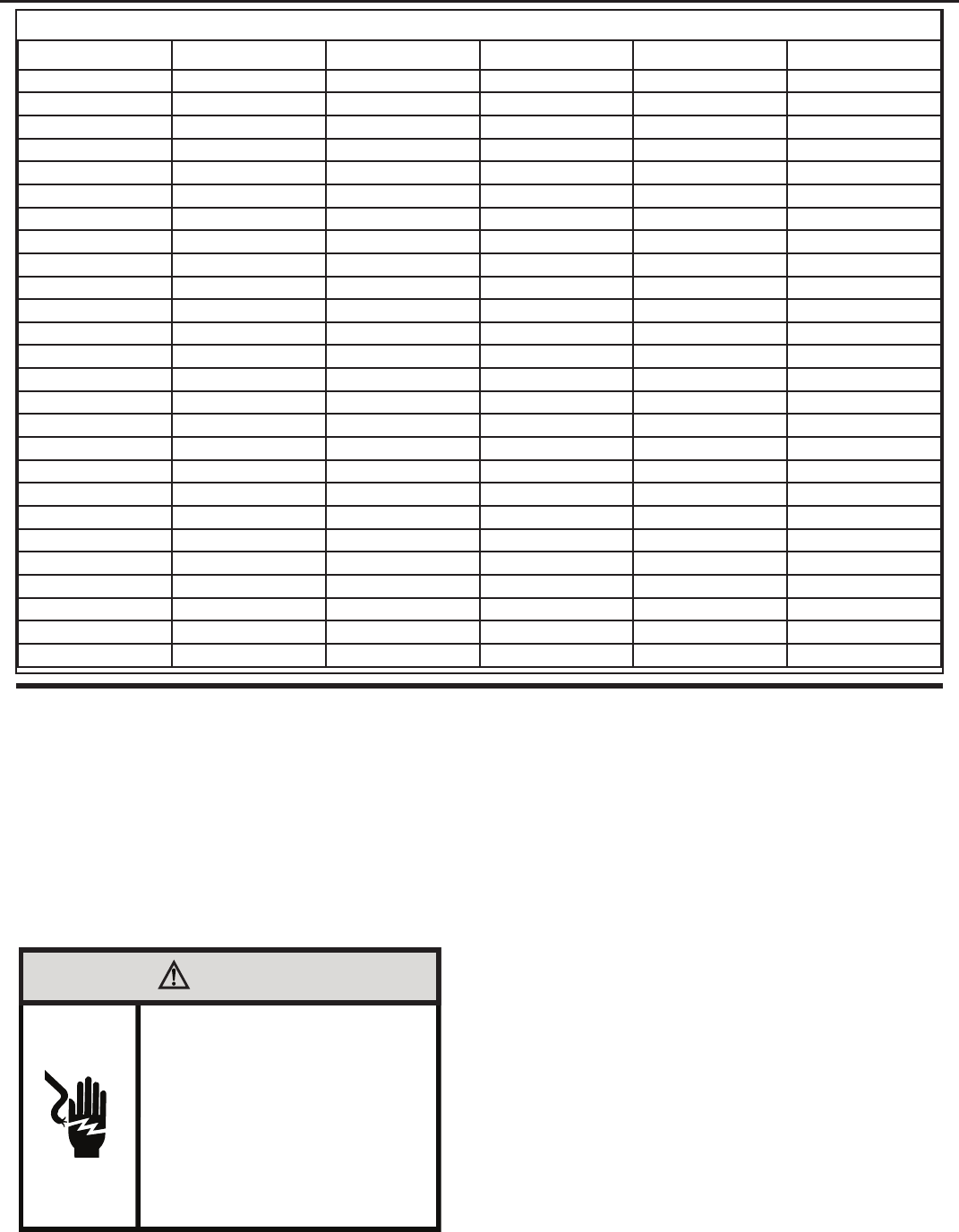

TABLE 2

Model Heater kW Power Cord Kit Voltage Amperage Receptacle

PDE07K 0.0 PXPC23000 230/208 15 NEMA 6-15r

PDE/PDH07K 2.0 PXPC23015 230/208 15 NEMA 6-15r

3.0 STD 230/208 20 NEMA 6-20r

PDE09K 0.0 PXPC23000 230/208 15 NEMA 6-15r

PDE/PDH09K 2.0 PXPC23015 230/208 15 NEMA 6-15r

3.0 STD 230/208 20 NEMA 6-20r

5.0 PXPC23030 230/208 30 NEMA 6-30r

PDE12K 0.0 PXPC23000 230/208 15 NEMA 6-15r

PDE/PDH12K 2.0 PXPC23015 230/208 15 NEMA 6-15r

3.0 STD 230/208 20 NEMA 6-20r

5.0 PXPC23030 230/208 30 NEMA 6-30r

PDE15K 0.0 PXPC23000 230/208 15 NEMA 6-15r

PDE/PDH15K 2.0 PXPC23015 230/208 15 NEMA 6-15r

3.0 PXPC23020 230/208 20 NEMA 6-20r

5.0 STD 230/208 30 NEMA 6-30r

PDE/PDH07R 2.0 PXPC26515 265 15 NEMA 6-15r

3.0 STD 265 20 NEMA 6-20r

PDE/PDH09R 2.0 PXPC26515 265 15 NEMA 6-15r

3.0 STD 265 20 NEMA 6-20r

5.0 PXPC26530 265 30 NEMA 6-30r

PDE/PDH12R 2.0 PXPC26515 265 15 NEMA 6-15r

3.0 STD 265 20 NEMA 6-20r

5.0 PXPC26530 265 30 NEMA 6-30r

PDE/PDH15R 2.0 PXPC26515 265 15 NEMA 6-15r

3.0 PXPC26520 265 20 NEMA 6-20r

5.0 STD 265 30 NEMA 6-30r

Electrical Wiring for 265 Volt

Models

NOTE: It is recommended that the PXSB subbase assembly, the

PXCJA conduit kit (or equivalent) be installed on all hardwire

units. If installing a ush-oor mounted unit, make sure the

chassis can be removed from the sleeve for service and

maintenance.

WARNING

Electrical Shock Hazard

Turn off electrical power before service

or installation.

ALL electrical connections and wiring

MUST be installed by a qualified

electrician and conform to the National

Code and all local codes which have

jurisdiction.

Failure to do so can result in property

damage, personal injury and/or death.

Power Cord Installation

All 265V PTAC/PTHP units come with a factory installed non-LCDI

power cord for use in a subbase. If the unit is to be hard-wired refer to

the instructions below.

To install the line voltage power leads and conduit

to chassis, follow the instructions below and refer

to Figures 25-27 on page 19. PXCJA Conduit Kit

is required with this setup.

1. Follow the removal process of the chassis’s junction box

(Figure 25, step 2, page 19).

2. Prepare the 265V (or 230V) power cord for connection to the chas-

sis’ power cord connector by cutting the cord to the appropriate

length (refer to Figure 26 and follow Figure 15). Power cord harness

selection shown on Table 2 on page 14.