www.fmiproducts.com

113084-01L 11

INSTALLATION Continued

WARNING: Never connect

-

Installation Items Needed

Before installing heater, make sure you have

the items listed below.

• external regulator - propane/LP only (sup-

plied by installer)

• piping (check local codes)

• sealant (resistant to propane/LP gas)

• equipment shutoff valve *

• test gauge connection *

• sediment trap

• tee joint

• pipe wrench

* A equipment shutoff valve with 1/8" NPT

tap is an acceptable alternative to test gauge

connection. Purchase the optional equipment

shutoff valve from your dealer.

The gas inlet connection for the stove heater

is located on the lower right-hand side of stove

when viewed from the front of unit. The gas con-

nection can be made either through the bottom

right side or through the lower back opening as

illustrated in Figure 8. Make sure gas log heater

is secured to stove cavity assembly.

For propane/LP units, installer must supply

an external regulator. The external regulator

will reduce incoming gas pressure. You must

reduce incoming gas pressure to between 11"

and 14" of water. If you do not reduce incom-

ing gas pressure, heater regulator damage

could occur. Install external regulator with

the vent pointing down as shown in Figure 9.

Pointing the vent down protects it from freez-

ing rain or sleet.

CAUTION: Use only new,

-

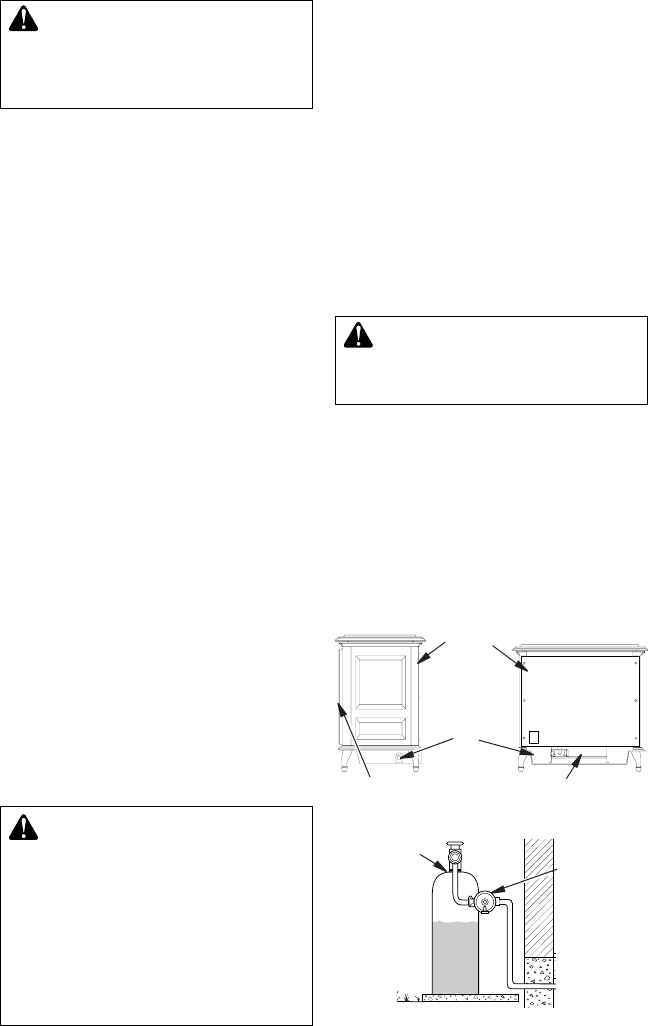

Figure 8 - Gas Regulator Location and

Gas Line Access Into Stove Cabinet

Gas Inlet

Connection

Access

Gas Log Heater

Side View

Figure 9 - External Regulator With Vent

Pointing Down

Back Stove

Panel

Stove Unit Front

Propane/LP

Supply Tank

External

Regulator

with vent

Pointing

Down

Installation must include a equipment shutoff

valve, union and plugged 1/8" NPT tap. Locate

NPT tap within reach for test gauge hook up.

NPT tap must be upstream from heater (see

Figure 10, page 12).

IMPORTANT: Install equipment shutoff valve

in an accessible location. The equipment

shutoff valve is for turning on or shutting off

the gas to the appliances.

Check your building codes for any special

requirements for locating equipment shutoff

valve to replaces.

Apply pipe joint sealant lightly to male threads.

This will prevent excess sealant from going

into pipe. Excess sealant in pipe could result

in clogged heater valves.

We recommend that you install a sediment trap

in supply line as shown in Figure 10, page 12.

Locate sediment trap where it is within reach

for cleaning. Install in piping system between

fuel supply and heater. Locate sediment trap

where trapped matter is not likely to freeze.

A sediment trap traps moisture and contami-

nants. This keeps them from going into heater

controls. If sediment trap is not installed or is

installed wrong, heater may not run properly.