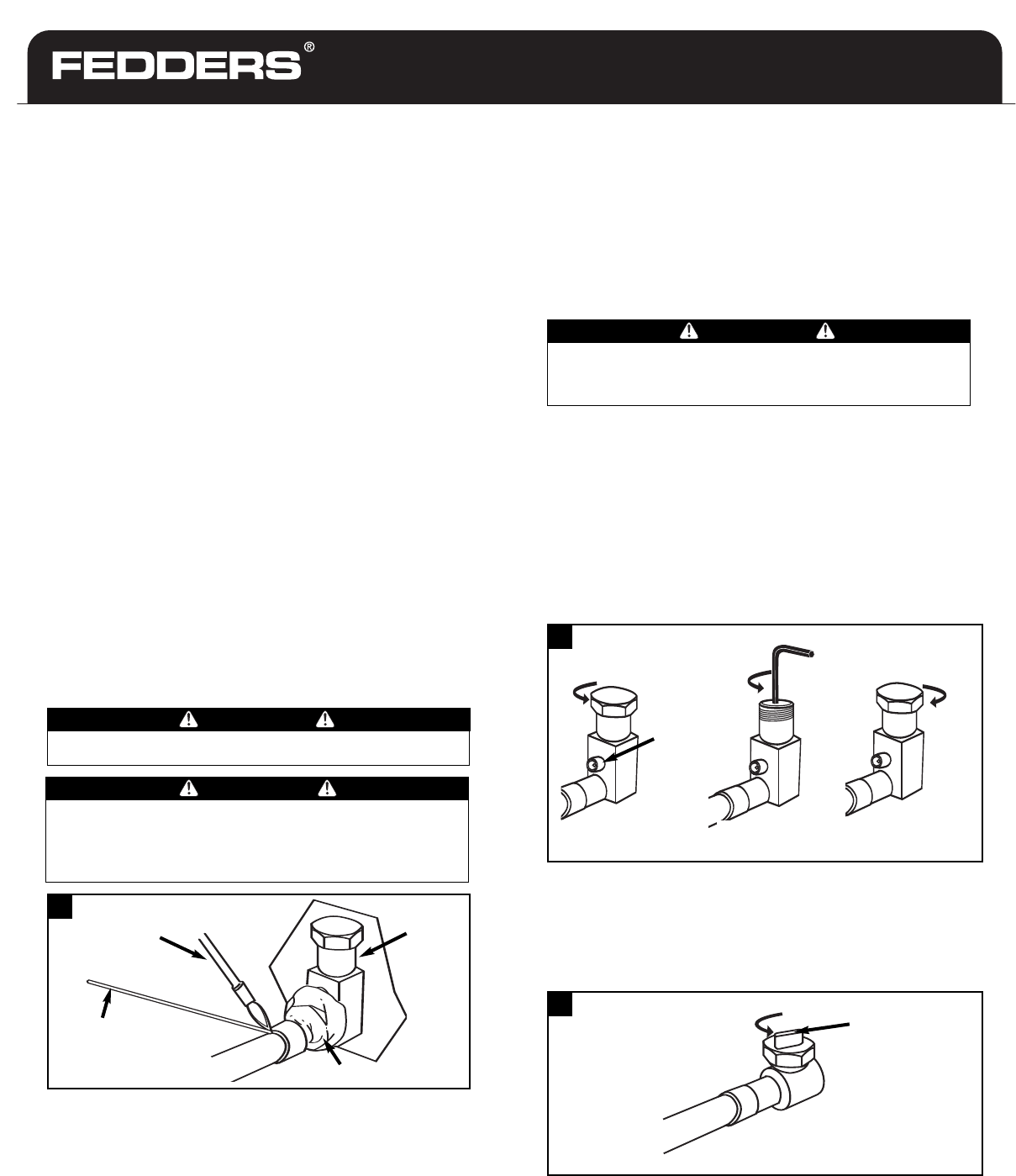

Opening the Service Valve (Step Valve)

NOTE: This is not a back-seating valve.

1. Remove the valve cap using an adjustable wrench.

2. Open the valve by inserting a hex wrench (3/16" for the

liquid line, 5/16" for the vapor line) into the stem and back

out counter-clockwise until the valve stem just touches the

retaining ring. Do not over tighten.

3. Replace the valve cap finger-tight, then tighten an

additional

1/12 turn or 1/2 hex flat. A metal-to-metal seal is

now complete.

Opening the Service Valve (Straight Valve)

NOTE: This is not a back-seating valve.

Open the valve by using an adjustable wrench to turn the

adjusting flange 1/4 turn counter

-clockwise. The flange will

come to a stop and the seal is now complete.

Remove cap

Replace cap

Open valve

Schrader

valve port

Open valve

Evacuation

The outdoor unit is factory charged. Evacuation is necessary

o

n the uncharged portions of the total system. Purge the

system with dry nitrogen. Then connect a vacuum pump and

a vacuum gage capable of accurately measuring below

1,000 microns vacuum depth. The deep vacuum method is

the most positive way of assuring a system is free of air and

l

iquid water.

WARNING

DO NOT USE AIR TO LEAK-CHECK BRAZE JOINTS.

DRY NITROGEN SHOULD BE USED TO LEAK-CHECK.

WARNING

T

orch

Brazing rod

Quenching cloth

Service

valve

3

Electrical Connections (cont.)

Connect control wiring

1. Route 24 volt control wires through control wiring grommet

and connect leads to control wiring.

2

. Use No. 18 AWG color coded, insulated wire. If thermostat is

located more than 100 ft. from unit, as measured along the

control voltage wires, use No. 16 AWG wire to avoid

excessive voltage drop.

3. All wiring must be NEC Class 1 and must be separated from

incoming power leads. Use furnace transformer, fan coil

transformer, or accessory transformer for control power.

N

ote: Use of available 24 volt accessories may exceed the

minimum power requirement. Determine total transformer

load and increase the transformer capacity or split the load

with an accessory transformer as required.

Final Wiring Check

Check factory wiring and field wire connections to ensure

terminations are secured properly

. Check wire routing to

ensure wires are not in contact with tubing, sheet metal, etc.

SERVICE VALVE CONNECTIONS

Braze Joints

1. Remove the valve core from the schrader port. Wrap a

quenching cloth around the service valve. Clean and flux the

joint and braze with brazing rod containing at least 10%

silver (such as silphos type brazing rod). DO NOT USE SOFT

SOLDER. Replace the schrader valve core after brazing has cooled.

2. Leak-check all braze joints at approximately 80 psi pressure,

purge and evacuate the lines.

Adjusting

flange

WARNING

ALWAYS HAVE A FIRE EXTINGUISHER AVAILABLE

WHEN WORKING WITH AN OPEN FLAME.

ALWAYS USE SAFETY GLASSES, PROTECTIVE

CLOTHING, AND WORK GLOVES.

115

117

116

IF THE INSTALLER IS MAKING UP HIS OWN LINE SETS,

HE MUST MAKE SURE THE TUBING IS CLEAN OF ANY

IMPURITIES OR MOISTURE.