32

ENVISION CONSOLE INSTALLATION MANUAL

ECM2 Blower Operation

Fan speeds will be selected through the user interface or

the facility management system. There will be a total of 12

speeds selectable with only three being selected at any

one time. The lowest numbered speed selection set to ON

will select the low-speed fan setting, the middle selection

set to ON will select the medium-speed fan setting and

the highest selection set to ON will select the high-speed

fan setting. If all selections are set to OFF the software

shall select speed setting 10 for low-speed, 11 for medium-

speed, and will select speed setting 12 for high speed. If

only one selection is set to ON, that selection will set the

low-speed fan setting, the medium-speed setting will be 11,

and the high-speed setting will be speed 12. The maximum

low-speed setting will be speed 10 and the minimum high-

speed setting will be speed 3.

In addition there is a low limit

setting in the software to prevent the ECM2 fan speed from

being set below acceptable limits for each unit size.

ECM2 Fan air flow “Soft Switch Settings”

A set of 12 “soft switches” accessible through the user

interface or building automation system are used to select

the three fan speed settings for the ECM2 fan motor.

The 12 soft switches work in exactly the same way as the

hardware switches used on the Premier control (Refer to

Fan Performance Data - ECM2 Motor for proper settings).

No more than three soft switches may be set to the “ON”

position. The first “ON” switch (the lowest number switch)

determines the “low speed fan” setting. The second de-

termines the “medium speed fan” setting, and the third

determines the “high speed fan” setting.

Emergency Heat/Network Enabled Output (BO5)

This output is set from the factory to enable/disable

emergency heat. If a problem occurs with the unit result-

ing in the compressor being locked out in heating mode,

the control will automatically enable this output to turn

on field installed electric heat. This output is interlocked

with the fan proving input BI-6 (Fan proving sensors must

be field supplied and installed). BI-6 must be connected

to PB2 position 3 (see unit schematic) in the field if no fan

proving sensor is desired. There is a configurable parame-

ter available through a BAS network that must be enabled

if this output is to be commanded over the BAS network.

MUI Alarm History Reporting

If a fault occurs the fault will be recorded in history for

display on the medium user interface in the History Menu.

Each fault type will be displayed in the history menu with

a number between 0 and 3. A reading of 3+ will mean

that fault has occurred more than three times in the past.

The history menu can be cleared with a power cycle only.

Alarm date and time are not included in the history.

Inputs & Outputs Configuration

Field Selectable Options

Water Coil Low Temp (Freeze Sensing) Limit Set Point (BI-5)

The water coil low temperature (freeze sensing) limit set

point input allows you to adjust the water coil low tem-

perature (freeze sensing) limit set point (AI-5). When the

jumper is installed on BI-5 (Wire #24) the water coil low

temperature (freeze sensing) limit set point is factory set

for 30°F. When the jumper on BI-5 (Wire #24) is removed

the water coil low temperature (freeze sensing) limit set

point will be 15°F.

Accessory Outputs (BO-7 and BO-8)

Accessory Output 1 will be energized 90 seconds prior to

the compressor output being energized. Accessory Output

2 will be energized with the fan output (BO-1). When the

corresponding compressor output is turned off the acces-

sory output will be deactivated immediately. These outputs

are selectable for normally open or normally closed opera-

tion through the Medium User interface or through the

Building Automation System.

Control Accessories

Zone Sensors

TAXXJ02 Room Command Module•

TAXXA01 LCD Room Command Module•

A99 Sensor•

MUI (LCD User interface) for diagnostics

and commissioning.

MUIK1 - Panel Mount, Portable•

MUIK2 - Wall Mount•

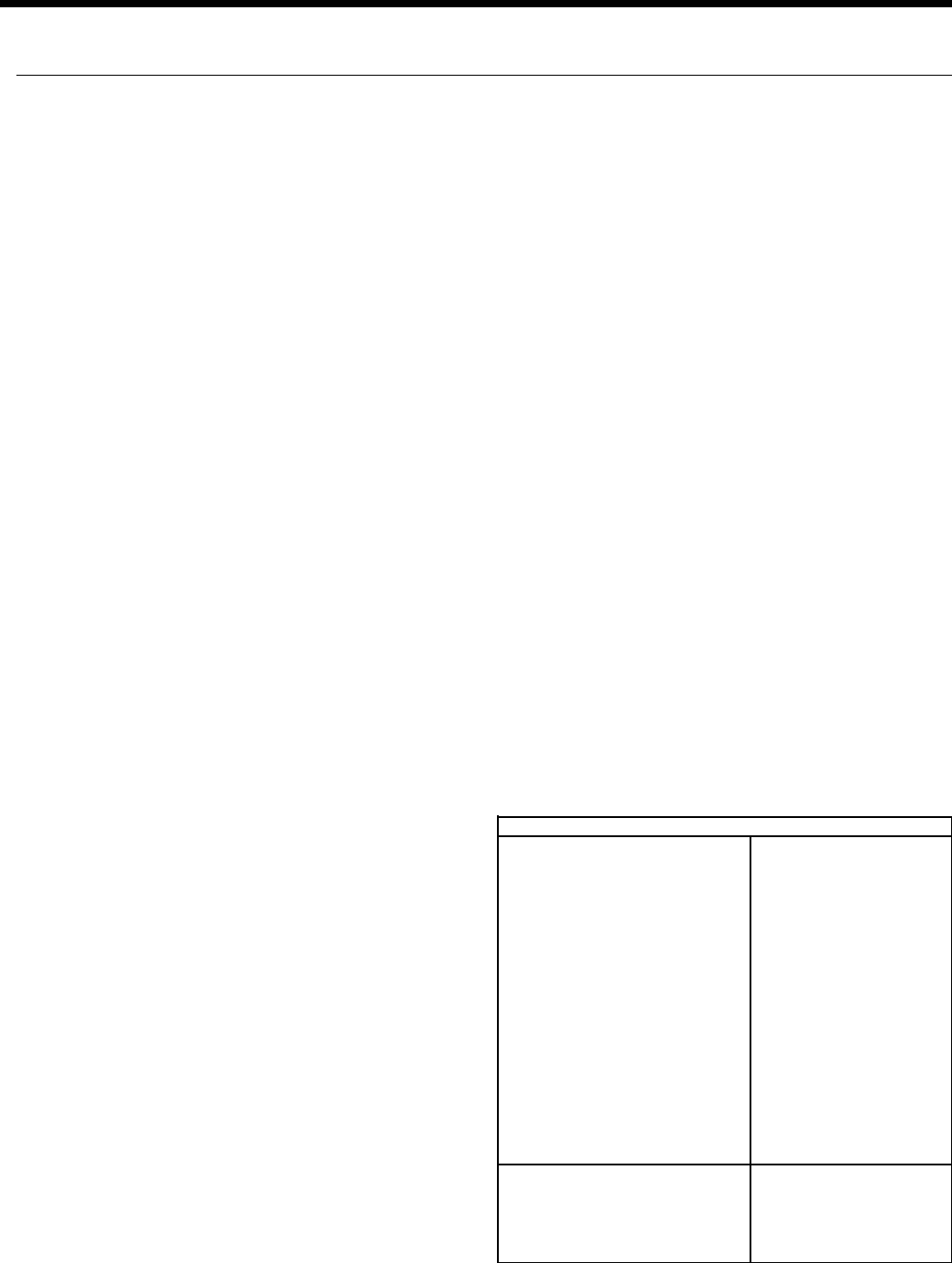

Envision Console Controls

Input Name Input Output Name Output

Zone Temp 1 AI 1 Fan Enable BO1

Relative Humidity Input AI 2 Comp – Low Capacity BO2

Condensate Level AI 3 Reversing Valve BO3

Universal Temp Input AI 4 Comp – Full Capacity BO4

Water Coil Low Temperature Limit AI 5 Network Output/EH Output BO5

Warm/Cool Adjust and Temp Occ AI 6 Alarm BO6

Accessory 1 Output BO7

Occupied BI 1 Accessory 2 Output BO8

Emergency Shutdown BI 2 Network Controlled Output B09

Stage 1 Low Pressure BI 3

Network Viewable Input 1 BI 4 ECM2 Fan PWM1

Water Coil Low Temp Limit Set Point BI 5 Network Controlled Output PWM2

Network Viewable Input 2 BI 6

Thermostat Y1 BI 7

Thermostat Y2 BI 8

Thermostat O BI 9

Thermostat G B10

Stage 1 High Pressure BI11

Compressor Proving BI12

XP10 Expansion Card

Input Name Input Output Name Output

Unused AI 1 Unused BO 1

Unused AI 2 Unused BO 2

Unused AI 3 Unused BO 3

Unused AI 4 Unused BO 4

SINGLE and DUAL STAGE WATER-TO-AIR