4. The convection blower will not function normally

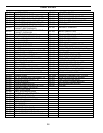

- Check all the connections between the controller, switch, and the convection blower

against the wiring diagram.

- If the convection motor will not run, apply 115 V to the motor directly. If the motor runs,

replace the fan controller. If the motor does not run, the convection blower has failed.

Replace the blower.

- If the convection blower runs on high at all times (no control with the fan controller),

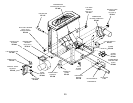

check the connections from the 160°F (71°C) sensor (located on the upper left side of

the firewall) and convection fan controller to the blower. Disconnect one of the wires

from the sensor, if control of the convection blower returns to the fan controller, replace

the sensor.

- If the motor is still on high, re-connect the sensor and replace the convection fan

controller.

5. Igniter- the pellets will not light

- Everything else in the stove operates but the igniter will not light the pellets

- Check all the electrical connections on the 120°F (49°C) temperature sensor located on

the exhaust channel.

- Check the connections at the igniter socket.

- Place a jumper wire between the two leads on the 120°F (49°C) temperature sensor. If

the igniter works. Replace the sensor.

- If the igniter does not work. Replace the igniter

NOTE:

The igniter should be a bright yellow or bright orange in color. If not Replace the igniter.

6. The auger motor will not function normally

- Make sure the exhaust blower is operating.

- Make sure the dial-a-fire is turned on.

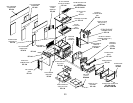

- Unplug the stove and open the side and back panels.

- Check all the connections to the auger motor, auger dial-a-fire, vacuum sensor, 200°F

(93°C) temperature sensor and the timing control module against the wiring diagram in

this manual.

- Check the condition of the vacuum hose (located on the left side of the stove). It should

not be cracked or torn and should be installed on the top air inlet tube on the vacuum

sensor.

- Check the manual reset button on the 200°F (93°C) temperature sensor. If this sensor

has been tripped, check for the cause of the over-heating before pushing the red button

in. Check auger for movement.

- If the auger still does not work, then apply 115 V directly to the auger motor. If the auger

motor does not work, replace it.

- By-pass the 200°F (93°C) temperature sensor with a jumper wire check the auger. If the

auger works replace the sensor.

- Check the voltage across the load pins of the timing module. It should be around 1-2 V,

cycling to line voltage during an auger pulse. If not, replace the timing control module.

- Check the vacuum sensor by placing a jumper wire between the blue wire and the black

wire that are attached to the sensor. If the auger works, test to see if the exhaust blower

is producing enough vacuum.

- To test the exhaust vacuum place a magnehelic gauge in the sensor end of the vacuum

tube. It should read 0.5wc”. If the reading is good then replace the vacuum sensor.

- If the auger motor still does not work, then attempt to by-pass the auger dial-a-fire

control by removing the leads from the timing control module’s second delay pins and

25