4

Enerco Group, Inc. |Gas-Fired Infra-Red Space Heaters OperatingInstructionsandOwner’sManual

a separate regulator must be installed ahead of the

heater.RefertoFigure2formaximumallowablepres-

sure for stated model and gas.

See heater rating plate for minimum gas supply pres-

sure “For the Purpose of Input Adjustment”

On a multiple heater installation it may be possible to

use one large capacity regulator or an individual regula-

tor for each heater. Nevertheless, it is recommended

practice to make the entire pipe system a loop. Contact

your local representative or the factory for proper gas

pressure reducing design stage.

WARNING: DO NOT EXCEED ½ P.S.I. INLET PRES-

SURE TO HEATERS SHOWN IN FIGURES 1 AND 2

6. ELECTRICAL

Allexternalwiringmustbeinaccordancewiththe

existingelectricalcode.Usewiringdiagramfurnished

with heater. Be sure electric supply characteristics

match those called for on the name plate. The unit

must be electrically grounded in accordance with the

National Electrical Code, ANSI/NFPA70, latest revision.

In Canada refer to Canadian electrical code CSA C22.1

7. THERMOSTAT & LOCATION

Make sure that the electrical characteristics of the

thermostat match those of the heater controls. For best

results thermostat should be positioned 5 ft. above

floor where air can circulate freely around it. DO NOT

MOUNT directly to cold-side wall, in direct drafts or

directly beneath the infra-red heater.

8. VENTILATION

a.Theminimumintakeandexhaustairopeningsshallpro-

vide for not less than 400 CFM for every 100,000 BTU

inputexceptthattheinltrationareamaybeincluded

intheintakearea.Theexhaustfanmustbeinterlocked

withtheheaterthermostat.Ifapowerexhaustfan

is used, it should be controlled by the thermostat or

humidistat

b.Wherenatural(gravity)ventilationisprovidedfor

exhaust,theopeningsmustbedistributedabovethe

heaters(preferablyatthepeakoftheroof)andthe

areas of openings shall not be less than 300 square

inches for every 100,000 BTU input.

9. OPERATIONS

Upon completion of electrical wiring, gas piping and

purging of gas lines to heaters, refer to the lighting

instruction plate attached to heater for proper lighting

procedure.

10. CLEANING INFORMATION

Blow out Venturi and burner face with compressed

air(25#max.pressure);alsocleanorices(seeFigure

2forcorrectsizedrill).Fordetailedmaintenanceand

cleaning instructions contact your local representative

or factory.

WARNING: GASKET BINDER MATERIAL USED

IN THIS HEATER ASSEMBLY WILL TEMPORARILY EMIT

ANODORAND/ORVAPOR.USEVENTILATION(aOR

b)ANDTHISCONDITIONWILLCLEARUPINAPPROXI-

MATELY 20 MINUTES AND WILL NOT REOCCUR.

WARNING: DO NOT ATTEMPT TO IGNITE THE

PILOT BY HAND ON HEATERS EQUIPPED WITH AUTO-

MATIC SPARK IGNITION.

WARNING: THE STATE OF CALIFORNIA REQUIRES

THE FOLLOWING WARNING: COMBUSTION BY-PROD-

UCTS PRODUCED WHEN USING THIS PRODUCT CON-

TAIN CARBON MONOXIDE, A CHEMICAL KNOWN TO

THE STATE OF CALIFORNIA TO CAUSE CANCER AND

BIRTHDEFECTS(OROTHERREPRODUCTIVEHARM).

NOTE: USE LATEST EDITION FOR ALL ANSI STAN-

DARD AND CANADIAN STANDARDS.

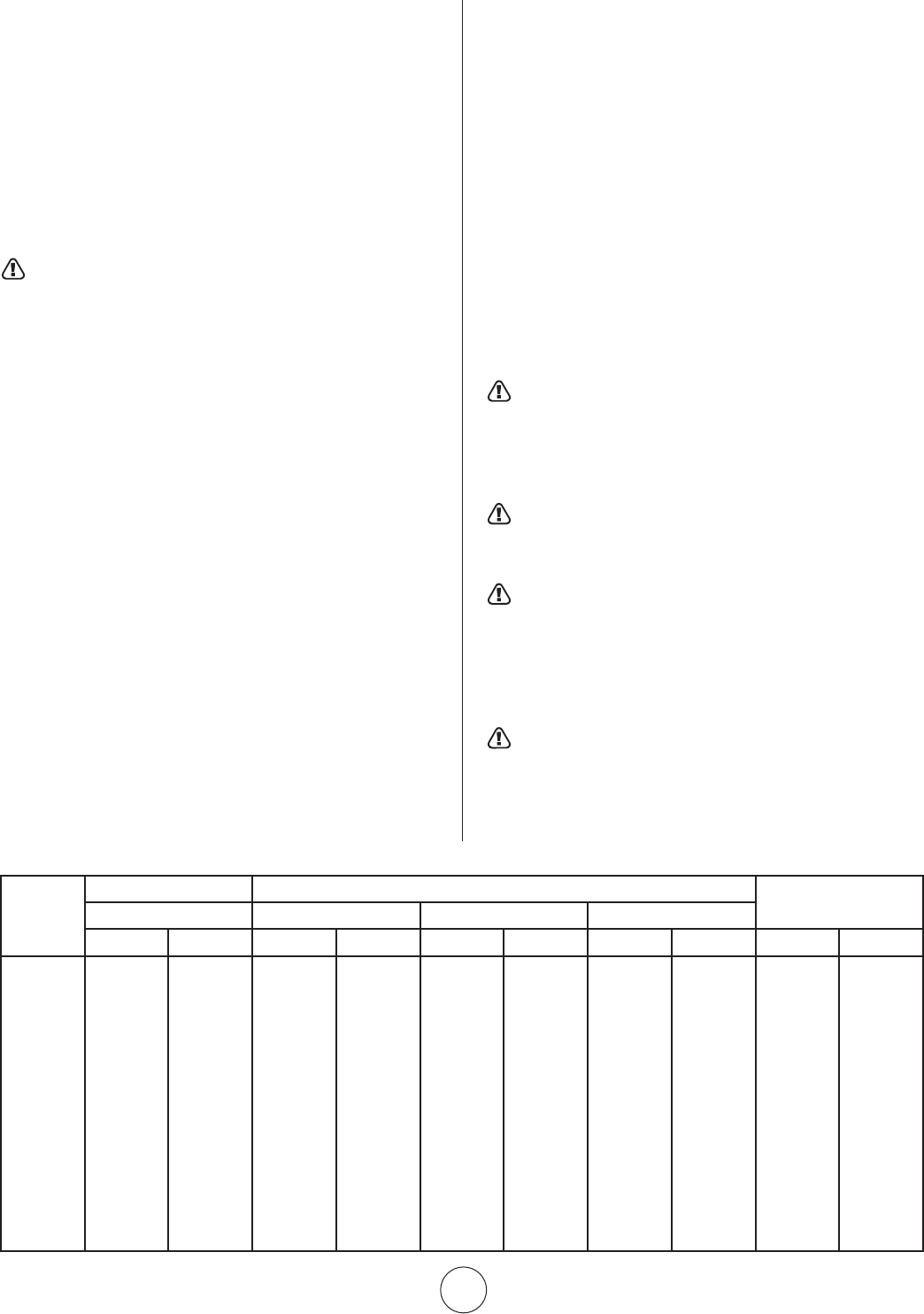

FIGURE 2

MODEL

NO.

BTU/HR. RATING GASSUPPLYPRESSURE(W.C.)

ORIFICE SIZE

GAS MIN. MAX. MANIFOLD

NATURAL PROPANE NAT. L.P. NAT. L.P. NAT. L.P. NAT. L.P.

4030 30,000 30,000 6.6” 11” 14” 14” 5.6” 10” 43 52

4040 40,000 40,000 6.8” 11” 14” 14” 5.8” 10” 37 49

8050 50,000 50,000 7.0” 11” 14” 14” 4.3” 10” 30 45

8060 60,000 60,000 7.0” 11” 14” 14” 5.8” 10” 29 43

8070 70,000 – 7.0” – 14” – 6.0” – 28 –

9080 80,000 80,000 7.0” 11” 14” 14” 5.8” 10” 37 49

9090 90,000 90,000 7.0” 11” 14” 14” 5.0” 10” 32 47

9100S 100,000 100,000 7.0” 11” 14” 14” 5.0” 10” 31 46

9100 100,000 100,000 7.0” 11” 14” 14” 4.3” 10” 30 45

9120 120,000 120,000 7.0” 11” 14” 14” 5.8” 10” 29 43

9140 140,000 – 7.0” – 14” – 5.5” – 28 –