www.enviromaster.com

13

Multi-zone Heat Pump Condensing Units

S2HA & T2HA REFRIGERANT PIPING INSTALLATION SECTION

The use of the superheat method is highly

recommended for field charging or checking

the existing refrigerant charge in a system.

Because each installation is different in terms

of indoor air flow, refrigerant line length, etc..,

the factory charge may not be correct for

every application. To assure the best perfor

-

mance from the air-conditioner, the refrigerant

charge should be checked and adjusted, if

need be, on each installation.

For proper superheat readings, a standard

low-side refrigerant gauge and an accurate

thermometer are needed. A mercury or

stem-type thermometer is not adequate

for suction-line temperatures. We recom

-

mend electric thermocouple thermometers

(available at most refrigeration wholesal

-

ers); however an accurate remote-bulb

thermometer can be used. When mea

-

suring the line temperature, be sure the

thermometer is well insulated to assure

accurate measurements. The chart below

gives superheat values at various outdoor

temperatures. Allow at least 5 minutes run-

ning time between charge adjustments for

the unit to stabilize.

The S & T series (S2HA, T2HA, T3HA &

T4HA) has manifold access points on each

of the service valves for the high and low

pressures in cooling mode. There is an

additional “common suction” access point

above each service valve set to provide low

pressure access in the heating mode as both

service valves are at high side pressure.

FIELD CHARGING

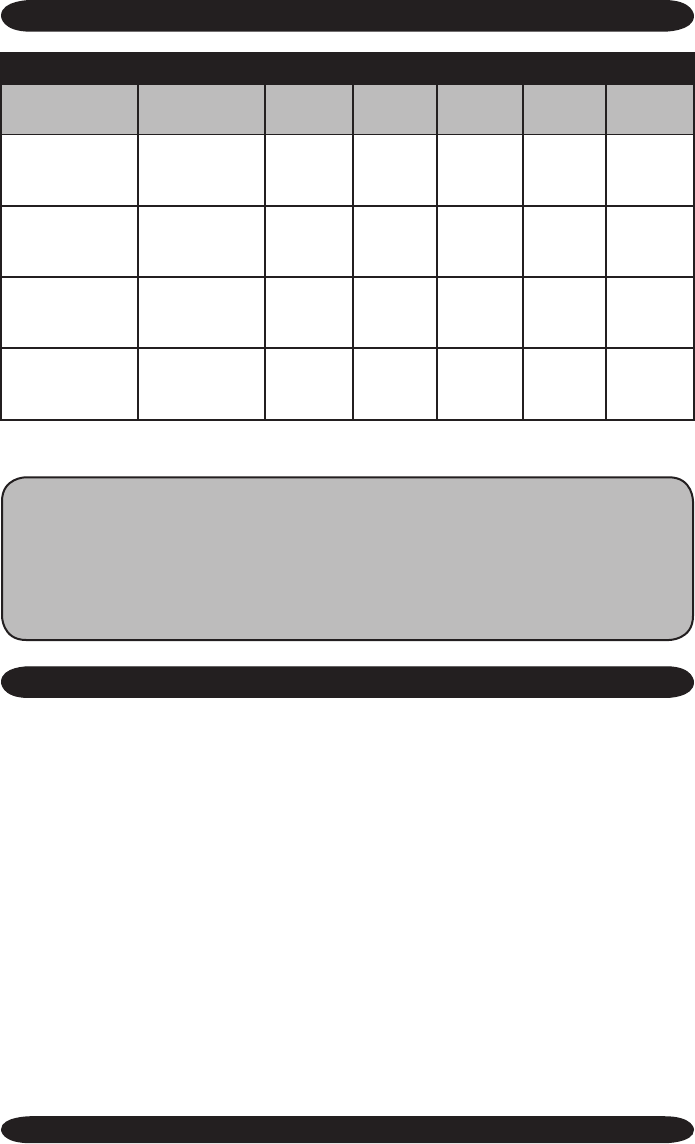

S2HA & T2HA REFRIGERANT CHARGE TABLE

Circuit

Capacity Btuh

Evaporator

Pairing

Line

Chg/ft

Line

Length

Line

Adjust

Factory

Charge

Total

Charge

9000

WLHA09

CAHB12

0.25 oz

10 ft

25 ft

50 ft

3 oz

6 oz

13 oz

42

45 oz

48 oz

55 oz

12000

WLHA12

CAHB12

0.25 oz

10 ft

25 ft

50 ft

3 oz

6 oz

13 oz

46

49 oz

52 oz

59 oz

18000

WLHA24

CAHB24

0.56 oz

10 ft

25 ft

50 ft **

6 oz

14 oz

28 oz **

80

86 oz

94 oz

108 oz

24000

WLHA24

CAHB24

0.56 oz

10 ft

25 ft

50 ft

6 oz

14 oz

28 oz

80

86 oz

94 oz

108 oz

** Any 18,000 Btuh circuit with more than 57 feet of tubing (> 112 oz of total refrigerant charge) requires a 25W

wrap around Crank Case Heater.

IMPORTANT NOTES:

1. To find the charge adjustment and system charge for any evaporator and

tubing length:

Line Adjustment = (Line Chg/Ft) x Line Length

System Total = Factory Charge + Line Adjustment

2. Round to the nearest ounce and allow for gauges and hoses.

3. Use R22 refrigerant.