www.enviromaster.com

12

Multi-zone Heat Pump Condensing Units

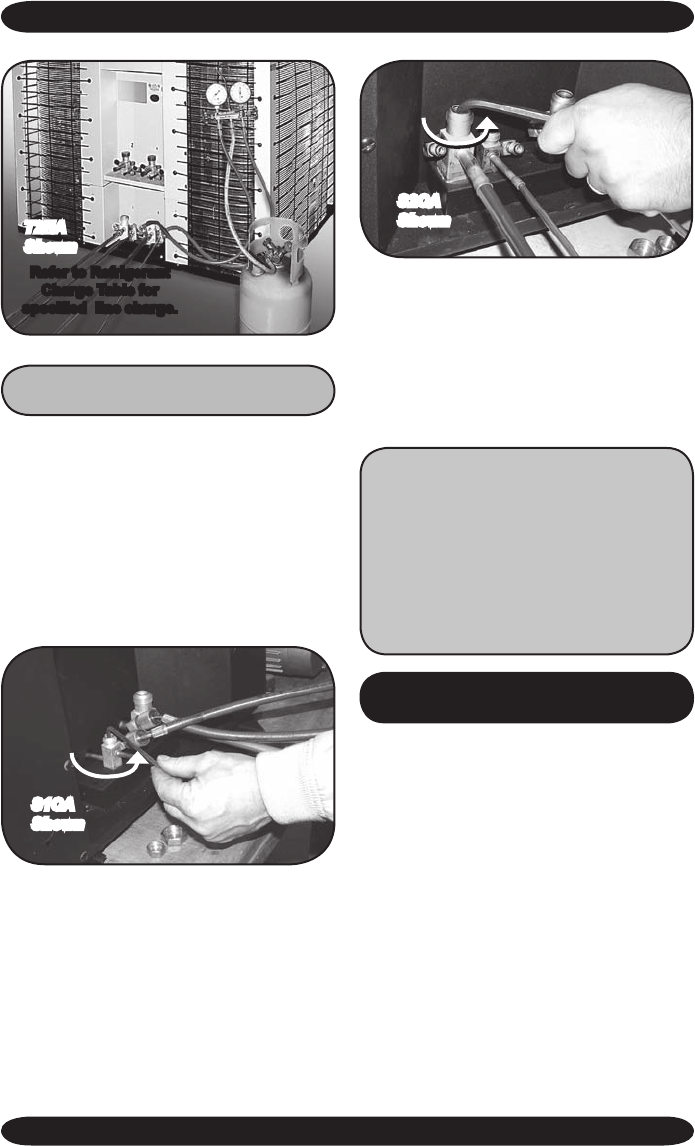

9. Once certain of a good evacuation and

leak free joints, back-seat the valves

(counter-clockwise) to open and allow

factory charge to fill lines and indoor

unit.

11. Refer to Field Charging Charts to “fine

tune” the refrigerant charge to meet

your conditions.

10. Charge to proper weight, charge based

on feet of interconnect (table on next

page)

Note: Charging should be done with a

dial-a-charge or weighed in with a scale.

S1CA

Shown

S2CA

Shown

The units are delivered precharged with

refrigerant for the condenser coil and the

evaporator. Charging of the field installed

piping is required. Refer to the refrigerant

charge table for the proper amount to be

added for the applications interconect pip-

ing. Unit service valves are solid brass, for

sweat connections.

IMPORTANT: All systems require field

charge adjustments. Refer to the "Refrig

-

erant Charge Tables" for proper weight

charge and to the supplied “Field Charging

Charts" for proper system pressures and

temperature at different outdoor condi

-

tions. Superheat should be used for final

system charge in cooling mode. Subcool

should be used for final system charge in

heating mode.

RECAP OF COMPLETING

PIPING CONNECTIONS

Pressure test all field installed piping and

the indoor air handler with nitrogen. Using

a suitable vacuum pump, evacuate the

tubing and indoor unit to 500 microns or

less, with service values remaining front

seated (closed).

Before releasing the refrigerant from the

condenser, be sure the manifold gauge set

is closed so as not to lose vacuum when

shutting down the pump.

Release refrigerant from the condensing

unit by back seating the service value. Al

-

len wrenches are used to open the valve.

Replace valve caps. Be Careful to not back

seat the valves past the snap flanges that

hold the valve core in place.

S2HA & T2HA REFRIGERANT PIPING INSTALLATION SECTION

Refrigerant

R22

Refer to Refrigerant

Charge Table for

specified line charge.

T2HA

Shown