14

TROUBLESHOOTING

A volt/ohmmeter (VOM) and the Toilet Wiring Diagram may be required for this section.

Caution: Portions of this section will require that power be applied to the toilet. Keep hands away from

the flush ball, motor drive arm and rotor shaft to prevent personal injury during testing and troubleshooting.

The control module uses a microprocessor to provide all the automatic and timing functions. The module is under the

access cover. The control module has input and output status lights that can be used in troubleshooting the toilet.

The program in the microprocessor monitors the input and output signals during a normal flush cycle. If the inputs

or outputs do not follow the commands of the program, then the microprocessor may go into a "standby" mode and

flash an "error code.” The microprocessor is reset by placing the Mode switch in the SERVICE position temporarily,

then returning the switch to the NORMAL position.

A safety circuit in the control module monitors flush ball operation. If foreign objects or low voltage prevent the flush

ball from closing, this circuit prevents personal injury or damage to the flush valve motor. If this condition occurs,

reset the control module by placing the Mode switch into the SERVICE position temporarily, then returning it to the

NORMAL position.

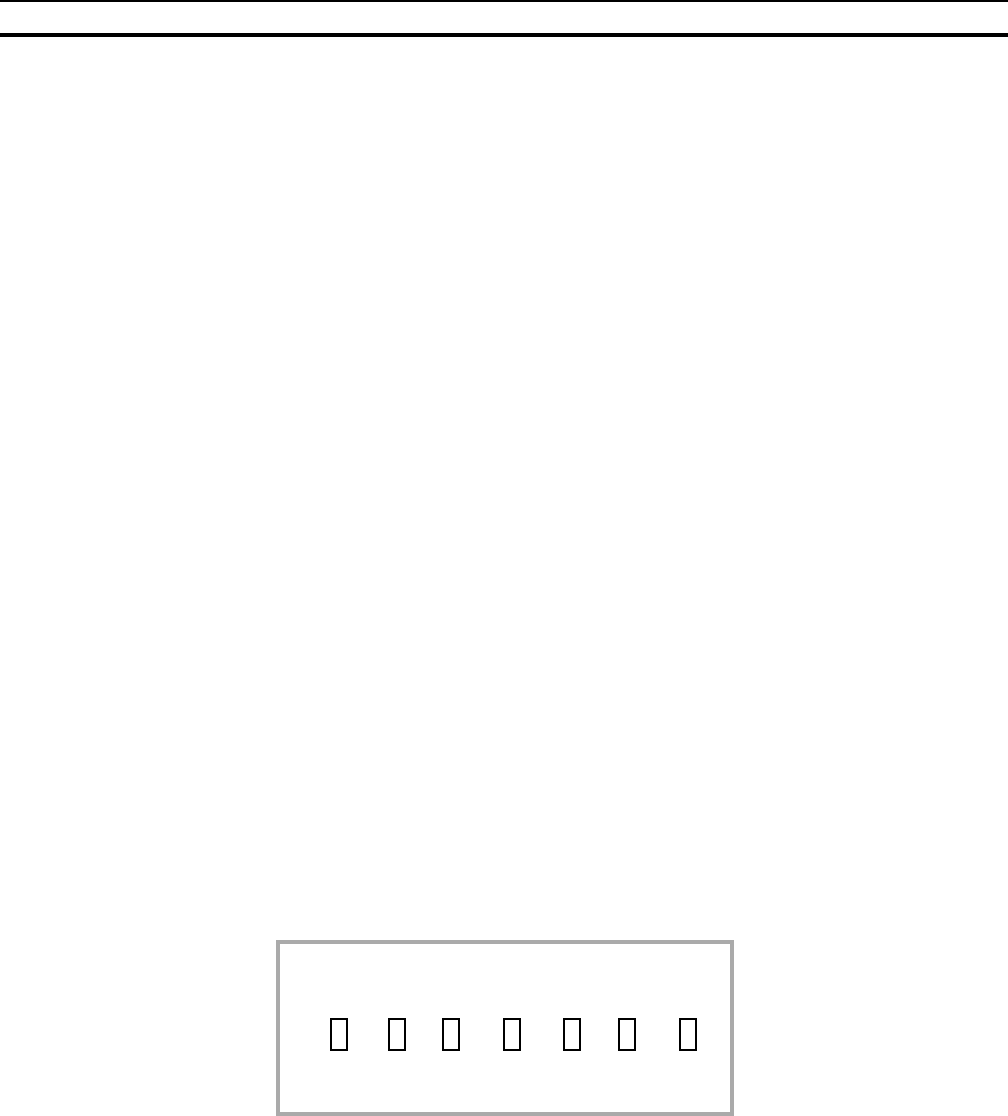

CONTROL MODULE STATUS LIGHTS

Status Light

1 Valve Closed

2 Valve Open

3 Flush

4 Add Water

5 Water Valve

6 Status

7 +5V

Function

Flush valve Closed Limit Switch engaged.

Flush valve Open Limit Switch engaged.

Flush handle or wall switch in "Flush" position.

Flush handle or wall switch in "Add Water" position.

Electric water valve energized.

Status/error codes

Input power

Color

Green

Green

Green

Green

Green

Green

Green

VALVE CLOSED

VALVE OPEN

FLUSH

ADD WATER

WATER VALVE

STATUS

+5V

LED 7

LED 6

LED 5

LED 4

LED 3

LED 2

LED 1

Status Light

6

6

6

ERROR CODES

Condition

Mode Switch in SERVICE position

VALVE OPEN Limit Switch problem

VALVE CLOSED Limit Switch problem

No. of Flashes

1

1

2

Pause

.5 sec.

2 sec.

2 sec.