4 5

CONNECTING THE WATER SUPPLY

● Pipework is not supplied

● All pipework should be installed using good plumbing

practice. We recommend 22mm mains cold water supply

is used.

● Install a Stop Cock Valve before the cold water inlet

assembly on the incoming mains water supply so the unit

can be isolated if required.

COLD WATER VALVE

The combined cold water valve (supplied) can be connected

anywhere on the cold water mains prior to the unit. It can even

be located at a point near to where the mains supply enters the

premises if this is more convenient. When installing the cold water

valve, ensure that the arrow is pointing in the same direction as

the mains water supply flow when connecting, see fig 2.

The cold water balancing port, on the valve, allows you to

connect the cold water mains to the rest of the property thus

giving balanced pressure throughout. If this facility is not

required leave the cap on.

DRAIN TAP

A drain tap to drain the unit must be fitted to the cold-water inlet

pipe somewhere between the

SCx unit and the cold water

valve assembly and at as low a level as possible, see fig. 1.

PIPEWORK TO TAPS

Ideally a 22mm pipe run should supply the outlets throughout

the property with short lengths (max 1 metre) runs of 15mm

going to baths, showers, and basin taps. Smaller bore pipe

can be used to suit taps.

SECONDARY CIRCULATION

This is particularly easy to fit on the SCx units; a Swept Tee (not

supplied) is needed for all indirect models if secondary

circulation is required, see page 6 fig. 3 for fitting. A non-return

valve (not supplied) must be fitted to prevent backflow. You

will need a pump to circulate the hot water (not supplied). The

return feed is in 15mm pipe and all work can be done on site.

STANDARD ENERGY LOSSES

The heat loss of each SCx Unvented Unit while maintaining

the temperature of the stored water at 65 degrees Celsius.

(See performance table below).

1) Tests carried out by BBA. Slight variations may occur with

changes to water mains supply pressure

SITING THE SCx UNIT

The unit can be placed anywhere convenient. Because it is

connected directly to the mains water supply it is equally

efficient on any floor – ground, first or second. Avoid areas

that may be subject to frost. Try to keep pipe runs as short as

possible for maximum economy, especially hot water

discharge pipes running down from the

SCx unit.

The unit can be fitted into a conventional airing cupboard

and does not require any additional insulation.

ALL SCx UNITS MUST BE STORED VERTICALLY

CHECK WATER PRESSURE & FLOW RATES

We suggest 1.5 bar pressure & 15 litres / minute flow rate to

be the minimum requirements for satisfactory operation. Less

than this the unit will still operate but you will not be able to run

two, or more, outlets at the same time. 85% of all U.K homes

have more than 2-bar pressure.

The mains supply must not exceed 16 bar. If it does a special

pressure-reducing valve will be required.

Important Note: - Stainless Steel Tectile push fit elbows are

fitted as standard to all

SCx Cylinders.

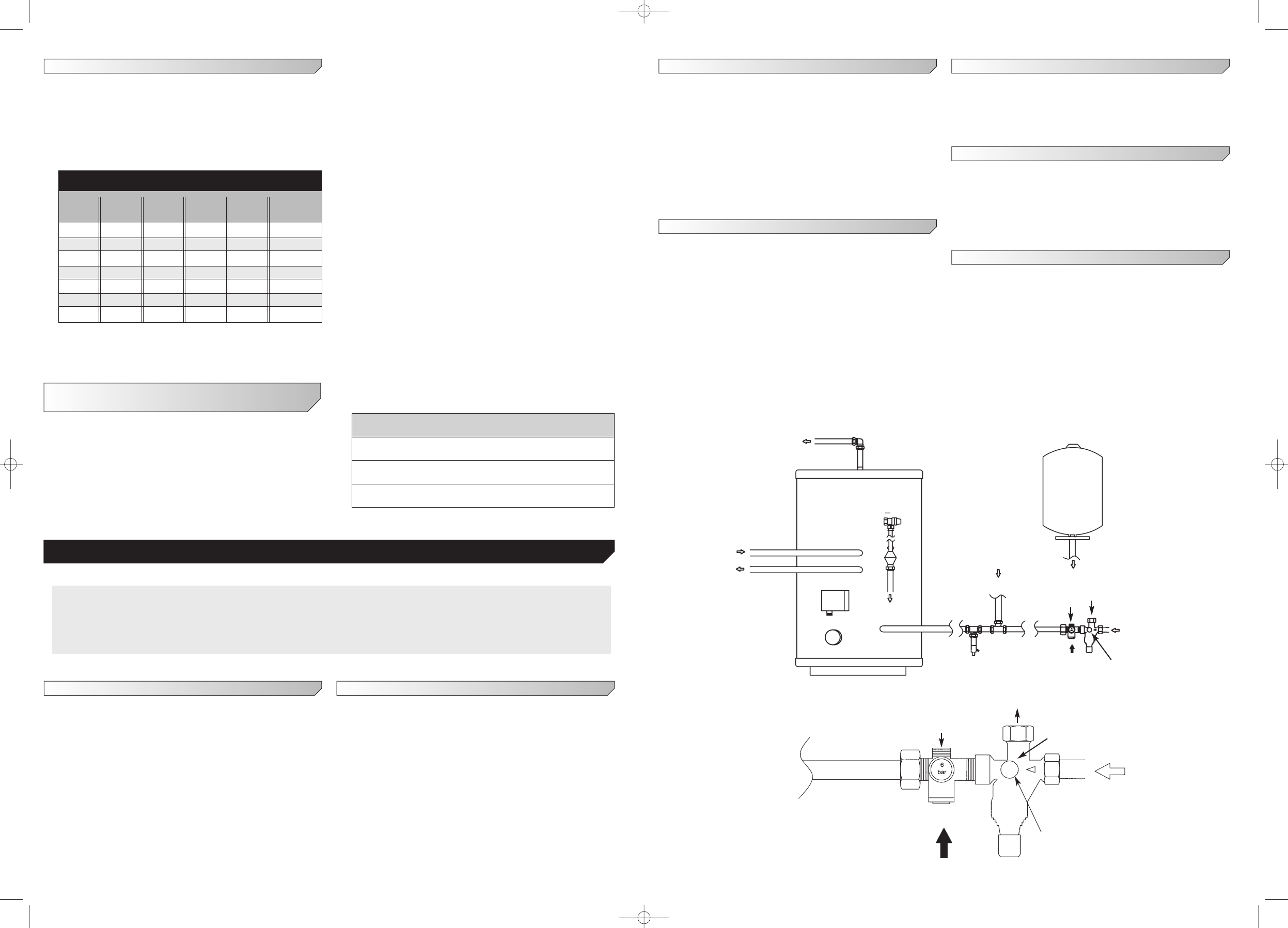

Fig.1

Fig.2

● 1 Element on IDH indirect models up to 305 litres and 80

litre DH direct model

● 2 Elements on DH direct models from 130 up to 305 litres.

Additional elements from 215 to 305 litres are available on

request.

● Cold-water control valve comprising line strainer, check

valve, pressure reducing valve set to 2.1 bar

● Expansion relief valve with non return valve set at 6 bar

● Tundish 15mm x 22mm F x F

● Temperature / Pressure relief valve set at 90 degrees

Celsius and 7 bar pressure relief (factory fitted)

● Motorised valve (indirect units only)

● Cylinder thermostat-factory fitted to cylinder, maximum

setting 85 degrees Celsius (indirect units only)

● Thermal cut out set to operate at 87 degrees Celsius plus

or minus 3 degrees (indirect units only)

● Option – Expansion vessel with capacity as below: -

Tank Size

80 to 130 Litres

150 to 215 Litres

255 to 305 Litres

Expansion Tank Required

12 Litres

18 Litres

25 Litres

Typical Indirect Tank installation using external expansion vessel option

Cold water inlet valve assembly

PRESSURE REDUCING VALVE SET

AT 3 BAR

WATER FLOW INLET SIDE OF TANK

WATER FLOW FROM EXPANSION

TANK TO 22MM FEMALE THREAD BEHIND

COVER

BLANKED

PORT

2) These figures relate to a 45 degree differential between

the stored water and ambient temperature

WITH AN SCx UNVENTED CYLINDER THE

FOLLOWING IS SUPPLIED AS STANDARD

Before commencing installation check that all the

components of your

SCx Unit are contained in the kit.

● 3KW Incoloy 825 heating element-incorporating

thermostat to 70 degrees Celsius and resetable safety cut

out set at 80 degrees Celsius

SCx UNVENTED INSTALLATION INSTRUCTIONS

WARNING: Under no circumstances must the factory fitted temperature pressure relief valve be removed. This will totally invalidate

any guarantee or claim. The cold-water inlet valve assembly must be fitted or the SCx unit will not perform satisfactorily.

DO NOT ATTEMPT TO VENT THE PRIMARY CIRCUIT THROUGH THE SCx UNIT.

All boilers should be installed to manufacturers instructions and the primary circuit through the SCx unit must be pumped.

WATER FLOW

HOT WATER OUTLET

PRIMARY FLOW

PRIMARY RETURN

TWIN

THERMOSTAT

IMMERSION

HEATER

WATER FLOW

TO COIL INLET

WATER FLOW

FROM COIL INLET

7 BAR / 90 DEGREES

PRESSURE &

TEMPERATURE

RELIEF VALVE.

TUNDISH

WATER FLOW

TO OVERFLOW

WATER INLET

DRAIN

COCK

SECONDARY

RETURN FLOW

SWEPT TEE

EXPANSION VESSEL

(WALL MOUNTED)

WATER FLOW TO

MANIFOLD VIA

FLEXIBLE HOSE

6 BAR

EXPANSION

RELIEF

VALVE

PRESSURE

REDUCING VALVE

SET AT 3 BAR

WATER FLOW

INLET SIDE OF TANK

BLANKED

PORT

WATER FLOW

FROM EXPANSION

TANK TO 22MM

FEMALE THREAD

BEHIND COVER

6 BAR

EXPANSION

RELIEF

VALVE

BALANCED

COLD WATER

OUTLET

SCx Performance

Nominal Heat up Heat up Reheat Reheat Heat loss in

Capacity Model IDH Model DH Model IDH Model DH 24 hrs

Litres Mins Mins Mins Mins kw/hr

80 33 64 23 53 1.12

130 28 115 21 90 1.50

150 33 138 24 104 1.82

175 27 167 24 124 2.10

215 35 212 30 153 2.64

255 42 263 35 184 2.73

305 50 313 42 220 2.88

Dimp-15278-SCx_Instructions 31/3/06 9:32 am Page 5