www.desatech.com

114370-01E8

INSTALLATION

Continued

CHECKING GAS CONNECTIONS

and connections, internal and

external to unit, for leaks after

WARNING: Never use an

-

PRESSURE TESTING GAS SUPPLY

PIPING SYSTEM

Test Pressures In Excess Of 1/2 PSIG

1. Disconnect log set with its individual

equipment shutoff valve from gas supply

piping system.

2. Cap off open end of gas pipe where equip-

ment shutoff valve was connected.

3. Pressurize supply piping system by either

using compressed air or opening main gas

valve located on or near gas meter.

4. Check all joints of gas supply piping sys-

tem. Apply noncorrosive leak detection

uid to gas joints. Bubbles forming show

a leak.

5. Correct all leaks at once.

6. Reconnect log set and equipment shutoff

valve to gas supply. Check reconnected

ttings for leaks.

1. Close equipment shutoff valve (see Fig-

ure 5).

2. Pressurize supply piping system by either

using compressed air or opening main gas

valve located on or near gas meter.

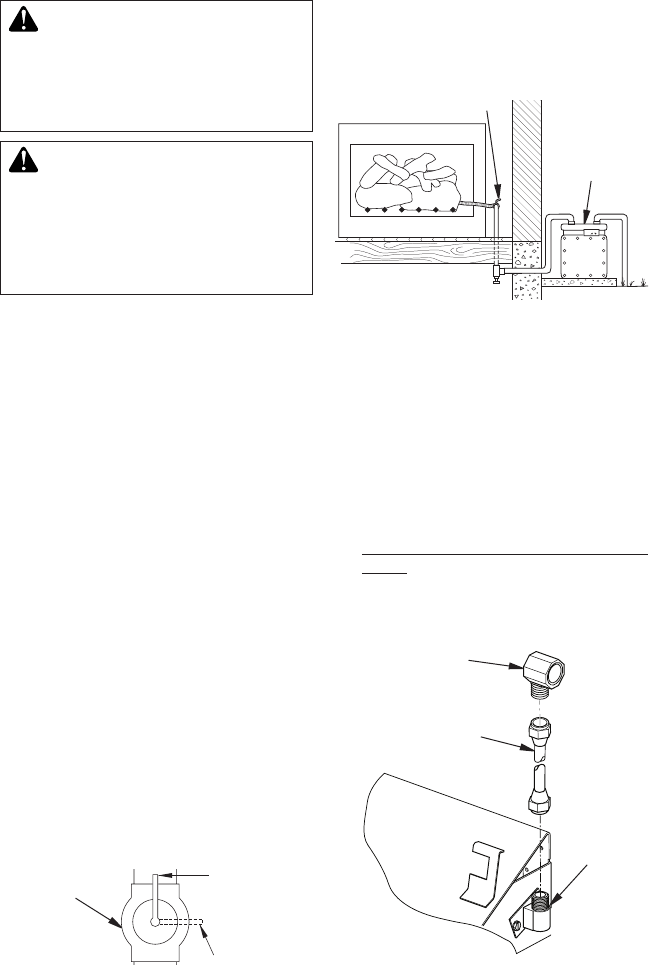

Figure 6 - Checking Gas Joints

HEARTH KIT ASSEMBLY AND

INSTALLATION

1. Determine which side the gas line will be

coming into the replace.

NOTICE: Unit comes preassembled with

gas inlet on right side. If your replace gas

supply is on the left, gas inlet should be

repositioned to left side of unit.

2. If gas supply line in your replace is on the

right side, continue to step 3. If not, see

Repositioning the Gas Inlet to the Left Side

of Unit, page 9.

3. Install adapter tting that comes with log

set into replace gas supply pipe (see

Figure 7). Seal using thread sealant.

Figure 7 - Connecting Adapter to Gas

Supply

Gas

Connector

Tube

Adapter

Fitting

Gas Inlet

Fitting

Equipment Shutoff Valve

Gas Meter

Figure 5 - Equipment Shutoff Valve

Equipment

Shutoff

Valve

Open

Closed

3. Check all joints from gas meter to equip-

ment shutoff valve (see Figure 6). Apply

noncorrosive leak detection uid to all

joints. Bubbles forming show a leak.

4. Correct all leaks at once.