www.desatech.com

110098-01H 13

FUEL LINES

(Procedure for Tightening Fuel

Lines)

1. Remove upper shell (see Upper Shell

Removal, page 11).

2. Use an adjustable wrench as a backup on

ttings.

3. Use 7/16" wrench and tighten fuel lines at

solenoid valve, pump and fuel lter canister

(if equipped) (see Figures 15 and 16).

SERVICE PROCEDURES

Continued

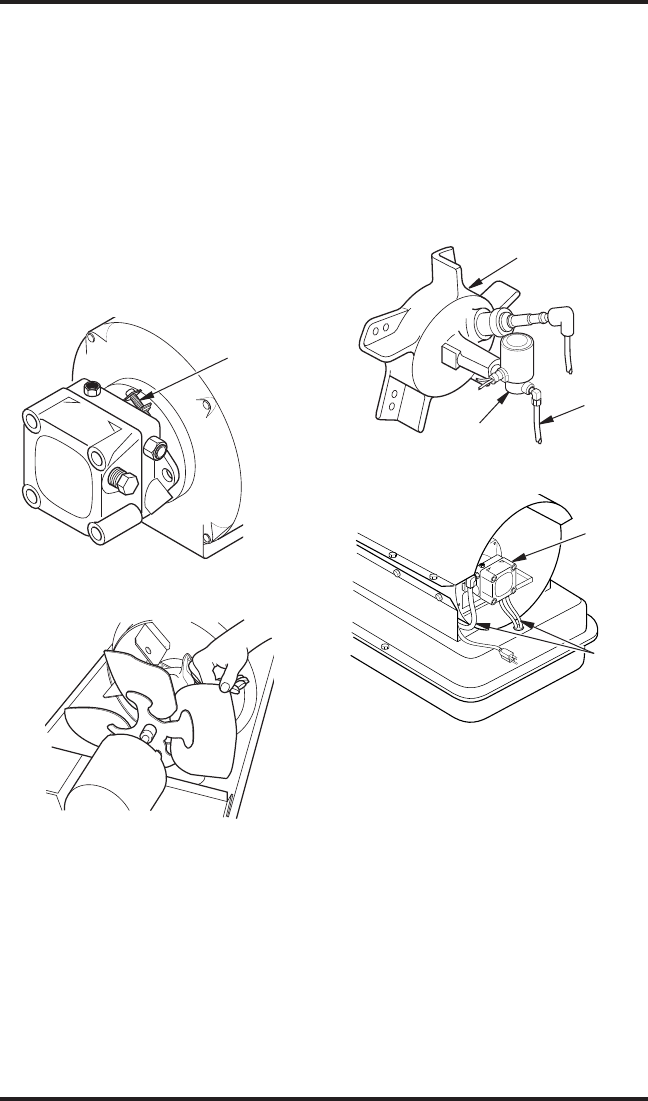

Figure 14 - Turning Fan with Hand

Fuel

Line

Solenoid

Valve

Burner Head

Fuel

Pump

Figure 15 - Fuel Line at Solenoid Valve

Figure 16 - Fuel Lines at Pump

Fuel

Lines

PUMP

(Procedure if Pump is Binding)

1. Remove upper shell (see Upper Shell

Removal, page 11).

2.

Loosen hex screw on ange clamp at rear of

motor with 5/16" nut-driver (see Figure 13).

3. Turn fan with hand (see Figure 14).

4. If fan turns freely, tighten screw on ange

clamp.

5. If fan does not turn freely, replace pump.

6. Replace upper shell.

Figure 13 - Location of Screw on Flange

Clamp

Hex Screw

On Flange

Clamp