www.desatech.com

110098-01H12

8. Inspect nozzle for damage. If damaged or

clogged, replace nozzle.

9.

Make sure plug is in place on burner head.

10. Replace nozzle into burner head and

tighten rmly (175-200 inch-pounds).

11.

Attach burner head to combustion chamber.

12. Install spark plug in burner head.

13. Attach spark plug wire to spark plug.

14. Attach fuel line to solenoid valve. Tighten

rmly.

15. Replace upper shell.

PUMP PRESSURE ADJUSTMENT

FOR HEATERS WITH FUEL FILTER/

CANISTER EXTERNAL TO PUMP

1. Remove pressure gauge plug from fuel

pump port marked “GAUGE.”

2. Install accessory pressure gauge (part

number 110380-01) to fuel pump port

marked “GAUGE” (see Figure 11).

3. Start heater (see Operation, page 5). Al-

low motor to reach full speed.

4. Adjust pressure. Use small flat blade

screwdriver to turn slotted screw at fuel

pump pressure adjusting port. Turn screw

clockwise to increase pressure. Turn

screw counterclockwise to decrease pres-

sure. See specications in Figure 11 for

correct pressure for each model.

5. Stop heater (see page 5).

6. Remove pressure gauge. Replace pres-

sure gauge plug in fuel pump port marked

“GAUGE.”

SERVICE PROCEDURES

Continued

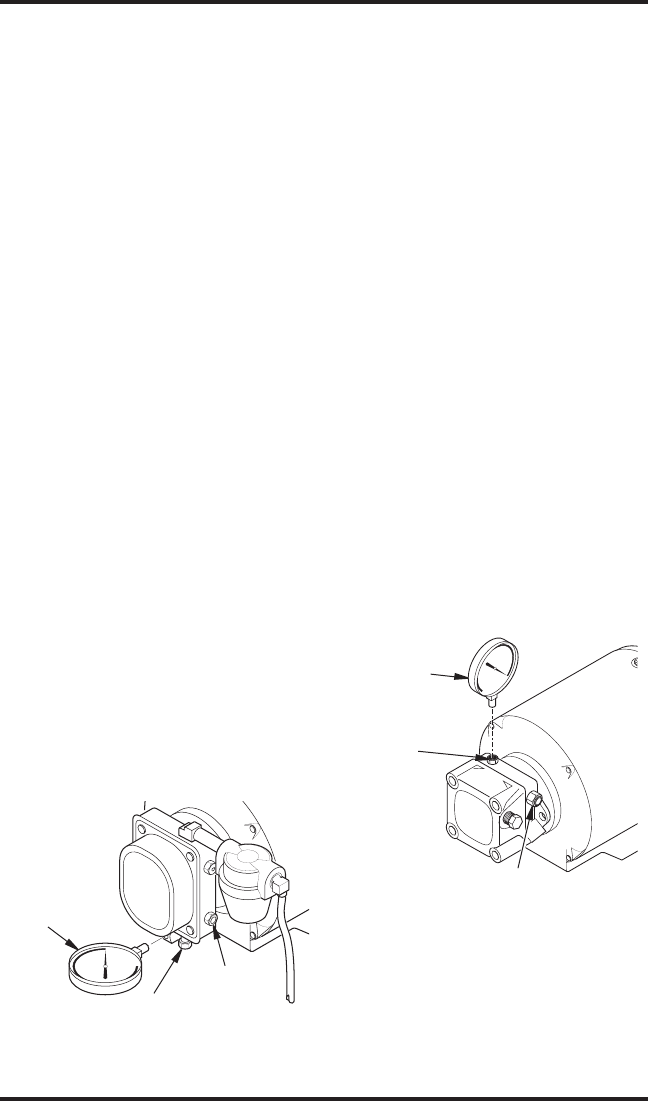

Figure 11 - Adjusting Pump Pressure

psi

Pressure

Gauge

Fuel Pump Port

Marked “GAUGE”

Fuel Pump

Port Marked

“PRESS ADJ”

Model Pump Pressure

350,000 Btu/Hr 100 PSI

600,000 Btu/Hr 110 PSI

PUMP PRESSURE ADJUSTMENT

FOR HEATERS WITH FUEL FILTER

INTERNAL TO PUMP

1. Remove pressure gauge plug from fuel

pump port marked “GAUGE.”

2. Install accessory pressure gauge (part

number 110380-01) to fuel pump port

marked “GAUGE” (see Figure 12). Do

not use bleeder valve port to check the

pressure. The bleeder valve port contains

pressure higher than operating pressure.

Setting pump pressure with gauge in the

bleeder valve port results in wrong operat-

ing pressure.

3. Start heater (see Operation, page 5). Al-

low motor to reach full speed.

4. Adjust pressure. Use small flat blade

screwdriver to turn slotted screw at fuel

pump port at top right side of pump. Turn

screw clockwise to increase pressure.

Turn screw counterclockwise to decrease

pressure. See specications in Figure 12

for correct pressure for each model.

5. Stop heater (see page 5).

6. Remove pressure gauge. Replace pres-

sure gauge plug in fuel pump port marked

“GAUGE.”

psi

Pressure

Gauge

Fuel Pump

Port Marked

“GAUGE”

Pressure

Adjustment Port

Figure 12 - Adjusting Pump Pressure

Model Pump Pressure

350,000 Btu/Hr 100 PSI

600,000 Btu/Hr 110 PSI