www.desatech.com

111916-01F

16

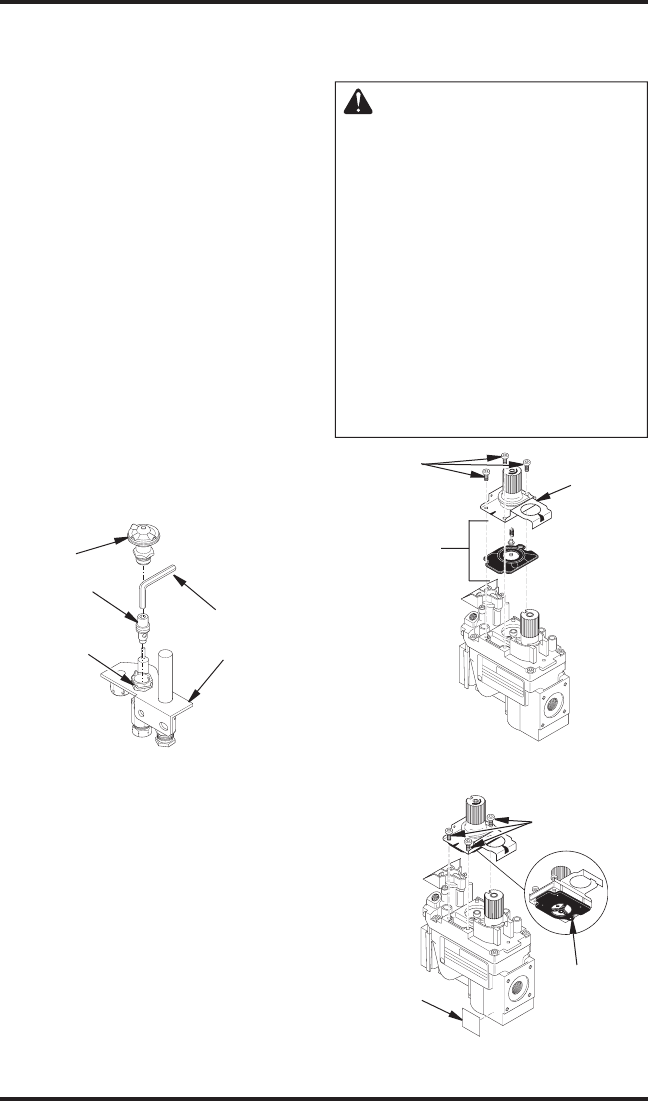

Figure 34 - Converting Pilot

Pilot Hood

Pilot Orifice

Barrel Clip

5/32" Allen

Wrench

Pilot Bracket

6. Locate air shutter at end of burner manifold (end

of tube burner for CD42M series). Loosen screw

and adjust air shutter to proper setting (see Burner

Flame Adjustment, page 13). Retighten screw.

7. Remove pilot hood by pulling up until it

disengages from barrel. Do not remove the

retainer clip (see Figure 34).

8. Remove pilot orifice from inside barrel using

a 5/32" allen wrench to unscrew the orifice.

9. Replace pilot orifice with LP orifice supplied

with this kit. The number 30 is stamped on the

sleeve for identification. Insert small end of

new pilot orifice into barrel and thread until

tight with the allen wrench.

10. Line up notch on pilot hood to the positioning tab

on barrel receiver and snap back into position.

IMPORTANT: Be careful not to bend or kink the

aluminum tubing during conversion. Make sure

the pilot hood and orifice are properly mated and

aligned after finishing this conversion.

Figure 36- Installing New Parts for Gas

Control Valve Conversion

HI

LO

O

F

F

P

I

L

O

T

O

N

Mounting

Screws

Rubber

Gasket

Identification

Label

3. Install the identification label enclosed with

gas valve regulator to the valve body where

it can easily be seen (see Figure 36).

WARNING: The conversion kit

must be installed by a qualified

service technician in accordance

with the manufacturers instruc-

tions and all applicable codes

and requirements of the authority

having jurisdiction. If any informa

-

tion is these instructions is not fol-

lowed correctly, a fire, explosion

or production of carbon monoxide

may result causing property dam-

age, personal injury or loss of life.

The qualified service technician is

responsible for the proper instal-

lation of this conversion kit.

CONVERTING FIREPLACE

FROM NATURAL GAS TO

PROPANE/LP GAS

Continued

CONVERTING CONTROL VALVE

Convert the gas control valve by swapping out the

valve regulator portion of the gas valve.

1. Using a TORX T20 or a slotted screwdriver,

remove and discard the three mounting

screws, pressure regulator tower and dia

-

phragm/spring components (see Figure 35).

2. Insure that the rubber gasket is properly

positioned on the new pressure regulator

assembly. Install new pressure regulator as

-

sembly to valve using new mounting screws

supplied with kit. Tighten screws securely

(approximately 25 in/lb). See Figure 36.

HI

LO

O

F

F

P

I

L

O

T

O

N

Figure 35- Removing Parts for Gas

Control Valve Conversion

Diaphragm/

Spring

Components

Mounting

Screws

Pressure

Regulator

Tower