www.desatech.com

901746-01E 11

INSTALLATION

Continued

The pilot is provided with a natural gas ori-

ce installed. For propane/LP gas you must

remove it and replace it with an propane/LP

orice. The hardware kit contains an pro-

pane/LP orice with a red stripe for converting

the pilot.

1. Gently loosen and remove the pilot line con-

nection from the bracket (see Figure 16).

2. Replace the injector with the propane/

LP pilot injector with the red stripe (see

Figure 16).

3. Replace and tighten the pilot line to the

bracket.

4. Continue with step 3 under Natural Gas

Installation, page 10.

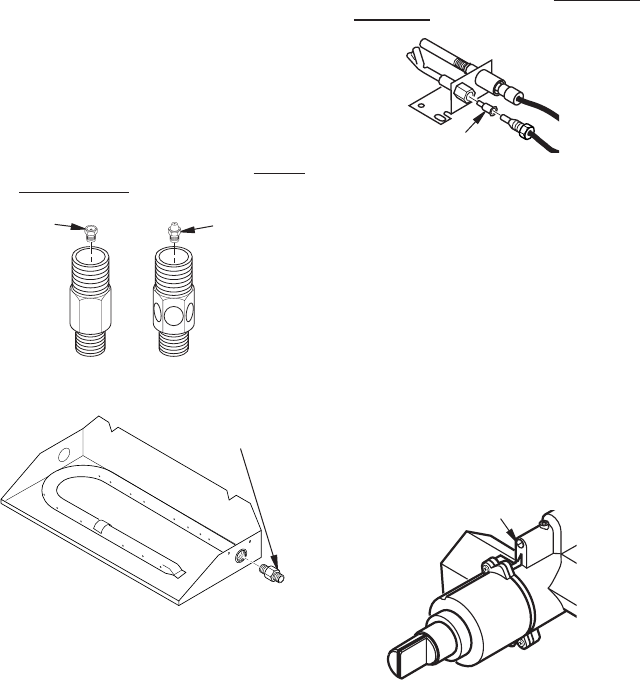

Figure 14 - Burner Inlet Fittings with

Injectors

NATURAL

GAS

FITTING

PROPANE/LP

GAS FITTING

Injector

for Natural

Gas

Injector for

Propane/LP

Gas

1. Remove burner inlet tting from burner

pan assembly. DO NOT remove orice

from this tting. The propane/LP burner

inlet tting is included in the hardware kit

(see Figure 14).

2. Be sure to use correct orice for your ap-

pliance. The hardware kit included with

this appliance contains two orices with

a cone-like shape. If you have an 18" set,

orice for burner inlet tting is red; for a 30"

set, it is black. If you have a 24" log set,

orice is already installed inside tting.

3. For an 18" or 30" set, use a 10 mm socket

or nut driver to remove orice from pro-

pane/LP burner inlet tting. Choose cor-

rect orice for your log set size and install

in place of orice you just removed.

4. Using thread sealant (resistant to action

of propane/LP gas) on larger end of tting,

screw burner inlet tting through hole

and into burner manifold, see Figure 15.

Tighten using a wrench.

5 . Follow steps 1 through 12 under Natural

Gas Installation, page 9.

Figure 15 - Remove Burner Inlet FItting

Burner Inlet Fitting

for Natural Gas

Figure 16 - Installing Propane/LP Pilot

Orice

Pilot Orice

After installation is complete and the unit has

been ignited, it may be necessary to adjust

the pilot. Use a small at-head screwdriver to

turn the ow adjustment screw on the manual

control valve (see Figure 17). Turn the screw

counterclockwise to allow more gas to ow

or clockwise to restrict gas ow. Be careful

to limit the turns to 2

1

/

2

from the fully closed

position. Further turning can result in gas

leaking at the adjustment screw and the pilot

ame size will diminish. The proper pilot ow

will result in a strong blue ame between 1/2"

and 1" long.

Figure 17 - Piliot Flow Adjustment Screw

Pilot Flow

Adjustment Screw