® The coalescing filter removes oil mists, separates

liquid oil and condensate, and automatically dis

-

charges these contaminants from the purifier.

¯ The activated carbon filter removes hydrocarbon

vapors to eliminate objectionable tastes and odors.

° The air-to-air heat exchanger heats the air before it

enters the catalyst cartridge ² to increase the carbon

monoxide conversion efficiency. At the same time,

this exchanger cools the purified air leaving the cata

-

lyst cartridge to increase the relative humidity for

greater worker comfort.

± The reheater (air-to-refrigerant heat exchanger) uses

waste heat from the refrigerant compressor to further

heat the air before it reaches the catalyst.

² The catalyst converts carbon monoxide to carbon

dioxide at an efficiency of 95 percent or higher. The

catalyst must be replaced once a year to assure effi

-

cient conversion.

³ The particulate filter removes fine particles to pro-

tect sensitive respirators and related equipment.

´ 100 percent of the inlet air is supplied as Grade D

compressed breathing air at the purifier outlet.

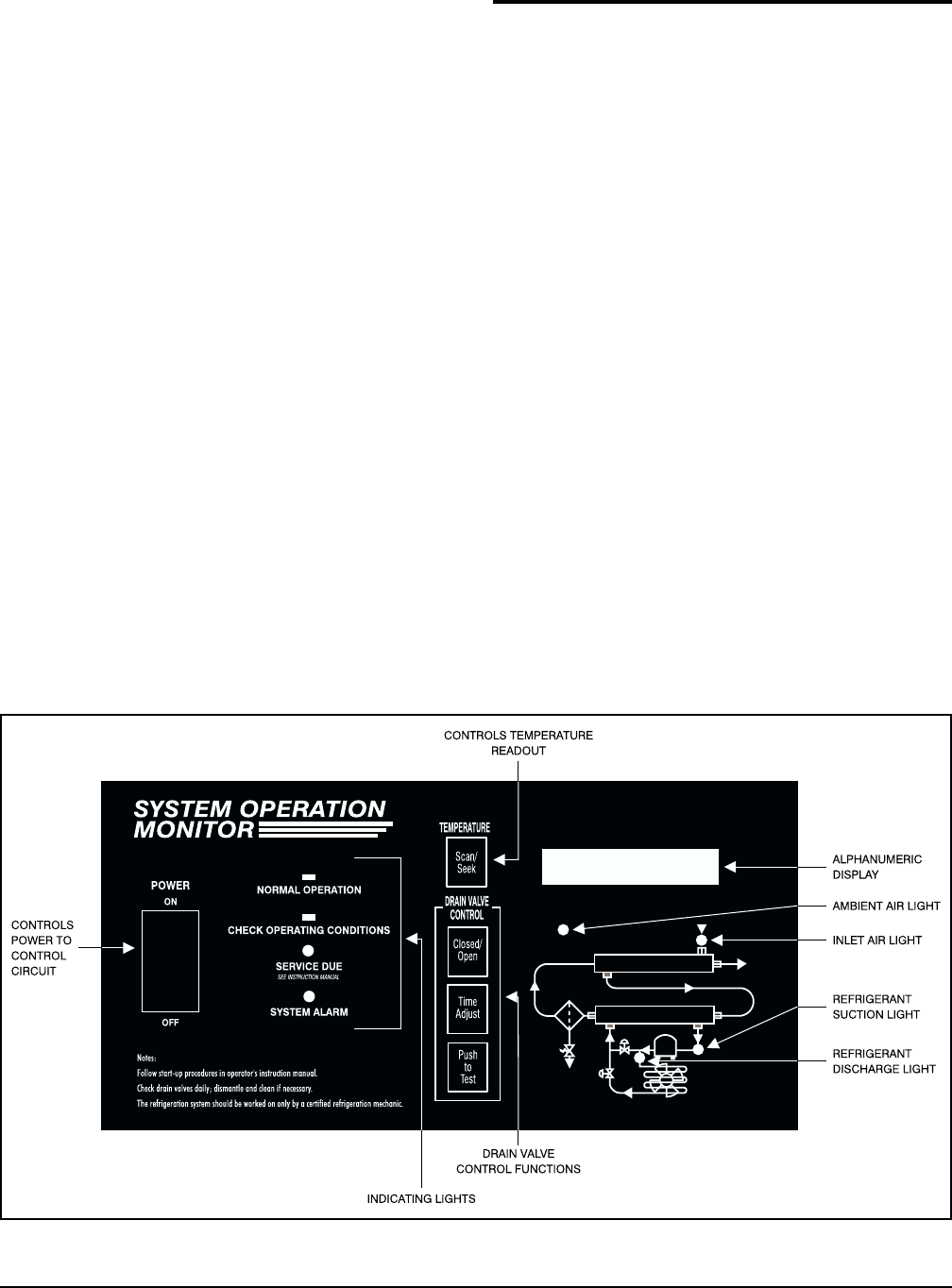

SYSTEM OPERATION MONITOR

The System Operation Monitor measures and displays

critical air and refrigerant temperatures, signals operat

-

ing conditions which may affect dryer performance,

and enables panel adjustment of the automatic drain

valve. There is also a light to indicate the need for rou

-

tine service, including replacement of the filter ele

-

ment.

The monitor (refer to Figure 2) consists of:

•

indicating lights

•

alphanumeric display

•

controls (push buttons) that provide access to

critical air and refrigerant temperatures

•

schematic with lights that correspond to the lo

-

cations of the temperature sensors in the system

•

drain valve controls

•

thermocouples

Indicating Lights

The System Operation Monitor has four indicating

lights: NORMAL OPERATION, CHECK OPERAT-

ING CONDITIONS, SERVICE DUE AND SYSTEM

ALARM. Table IV provides instructions for using the

indicating lights to monitor dryer operation.

Pyramid 8000

®

Series Purifiers (Bulletin 289) 5

Figure 2. System Operation Monitor