Clearance

Allow adequate clearance on all four sides of the puri

-

fier for cooling air flow and for service and mainte

-

nance access. Above the purifier, allow at least

one-half the height of Model 8DM25, 8DM50 or

8DM75 to replace cartridges. Above Model 8DM100

or 8DM150, allow the full height of the purifier. See

Table II for purifier dimensions.

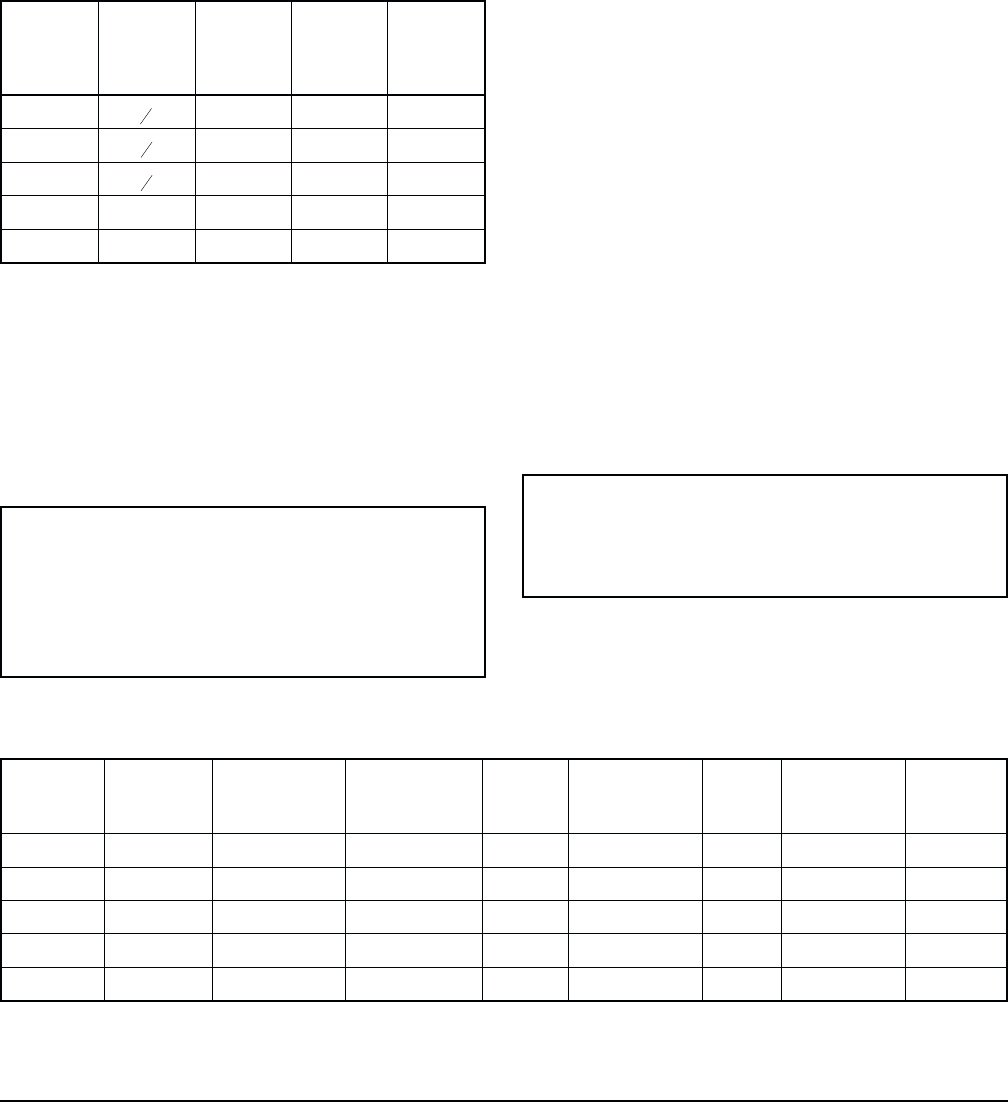

Table II

Purifier Dimensions*

Model

Inlet/

Outlet

Conn.

(in FPT)

Height Width Depth

8DM25

1

2

45 24 24

8DM50

3

4

45 30 30

8DM75

3

4

45 30 30

8DM100 1 55 36 36

8DM150 1 55 36 36

* All dimensions are in inches.

Ambient Air Temperature

Purifier ambient air temperature must be between 50°F

and 100°F. Higher temperatures (up to 120°F) can be

tolerated if inlet air flow is decreased (see Airflow sec-

tion). Operation outside the recommended ambient

temperature range will cause poor purifier perform-

ance.

DANGER

Never operate thepurifier in atmospheres be

-

low 50°F or above 120°F. Operation outside

this range will cause poor purifier perform

-

ance and may result in illness, injury or

death.

Location

Locate the purifier under cover in a clean, dry, well-

ventilated area. Install the purifier on a level base. Pro

-

tect the purifier from heavy vehicles or other moving

equipment likely to cause damage. Bolt the purifier to

the foundation if the installation area is subject to vi

-

brations. A bolt hole is located in each leg.

Air Compressor Equipment

Air compressor equipment must be located and main

-

tained to prevent the entry of oxygen-deficient air or

grossly contaminated air into the purifier . Do not op

-

erate lubricated compressors at temperatures high

enough to cause chemical breakdown of the lubricant.

Breakdown temperatures vary; contact the lubricant

manufacturer for details.

Install the purifier downstream of an aftercooler and

separator (with functioning drain valve) so that purifier

inlet air is between 40°F and 100°F and contains no

liquid water.

Air Piping and Connections

The customer must furnish all external piping. Piping

must be rated for the maximum operating pressure and

temperature given on the purifier data plate and must

conform to applicable codes. Support all piping. Do

not allow the weight of the piping to stress the purifier

connections.

DANGER

Do not hydrostatically test the piping with the

purifier installed in the air system. Water will

damage the catalyst.

Connect the compressed air supply to the purifier inlet.

Connect the breathing air distribution line to the puri

-

fier outlet. (See Table III for connection sizes.) Inlet

Pyramid 8000

®

Series Purifiers (Bulletin 289) 3

Table III

Purifier Specifications

Model

Rated*

Capacity

(scfm)

Inlet/Outlet

Connections

(inches FPT)

Electrical

Service

(V/Ø/Hz)

Running

Load

Amps

Refrigerant

Compressor

Power (hp)

Fan

Power

(Watts)

Refrigerant

Charge

(Type R-22)

Heat

Rejection

(BTUH)

8DM25 25 ½ 115/1/60 5.0 ¼ 5 2 lb 2,780

8DM50 50 ¾ 115/1/60 10.0 ½ 9 3 lb 6,000

8DM75 75 ¾ 208-230/1/60 7.0 ¾ 50 4 lb 6 oz 9,890

8DM100 100 1 208-230/1/60 7.0 1 50 5 lb 8 oz 11,060

8DM150 150 1 208-230/1/60 10.0 1½ 50 8 lb 8 oz 14,300

*Ratingconditionsare100°Finletairtemperature,100psiginlet airpressure,100%inletrelativehumidityand100°Fambienttemperature.If oper

-

ating conditions are different from rating conditions, consult Deltech for purifier capacity.