®

Dayton Installation, Operation, Maintenance and Parts Manual

Models 3E132 thru 3E134, 3E460 thru 3E462,

5VD57 thru 5VD66, 3VH34 thru 3VH37

E

N

G

L

I

S

H

21

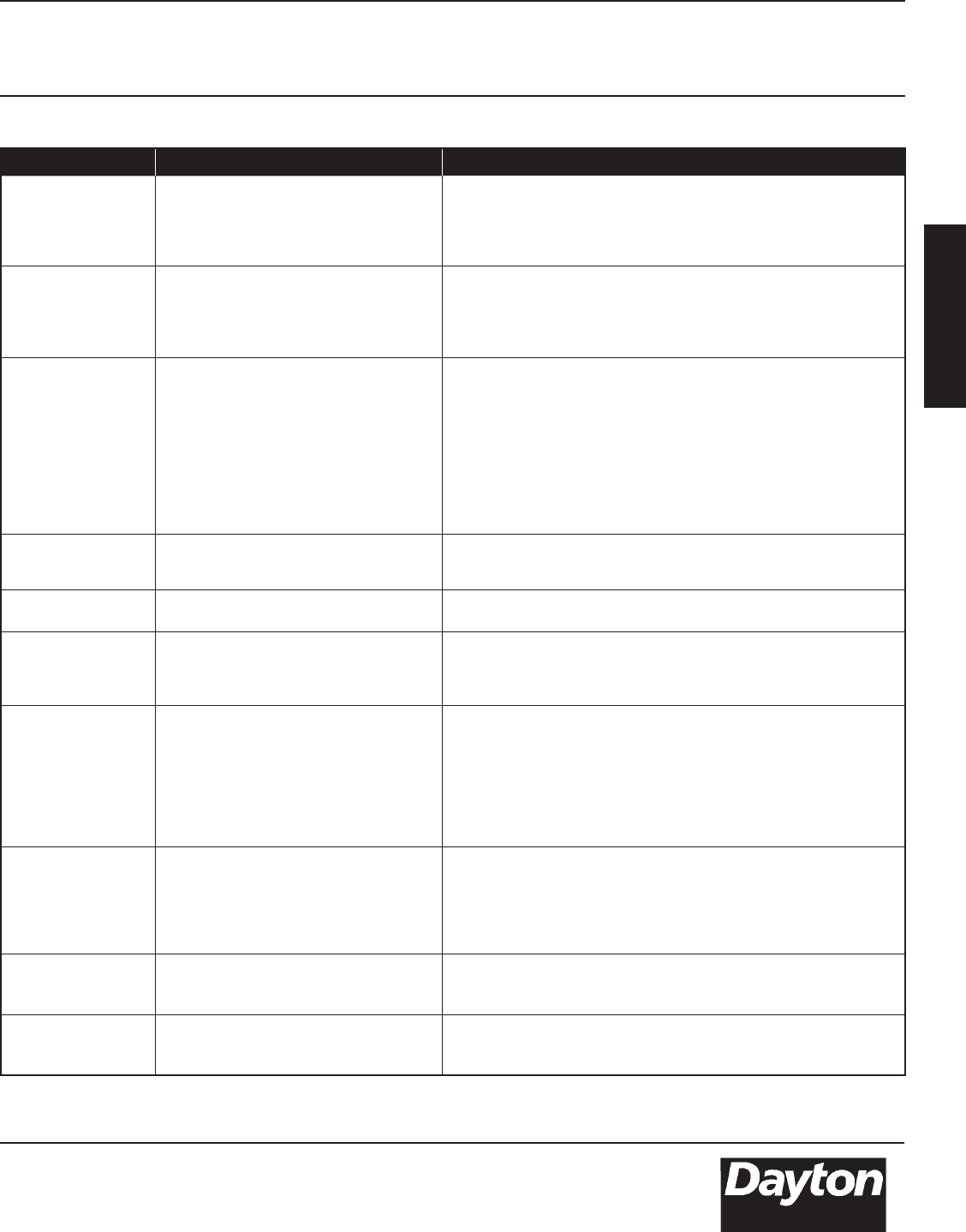

Symptom Possible Cause Corrective Action

Burning of gas-air

mixture inside

plenum (flashback).

• Heater mounted at incorrect angle.

• Excessive drafts.

• Gas leaking or blocked orifice/venturi.

• Separation of ceramic grids.

• Ceramic grids cracked.

• Mounting angle 20°-35° from horizontal.

• Relocate or shield from draft.

• Do not operate unit. Check with leak detector solution.

• Do not operate unit. Replace rayhead.

• Do not operate unit. Replace rayhead.

Delayed ignition. • Electrode out of specification.

• Low gas pressure.

• Partially blocked orifice.

• Improper orifice size.

• Incorrect gas.

• See figure 4.2.

• See Gas Supply section.

• Clean or replace.

• Consult dealer.

• Do not operate unit. See unit nameplate. Correct immediately.

Low ceramic surface

temperature, excessive

rollout or soot on

rods.

• Dirty or plugged rayhead ceramics.

• Partially blocked orifice.

• Low inlet gas pressure.

• Low manifold gas pressure.

• High manifold pressure.

• Foreign matter in venturi tube.

• Gas supply piping too small .

• Incorrect gas.

• See maintenance instructions.

• Remove and clean.

• See Gas Supply section.

• Adjust main valve regulator for 6” W.C.P. natural gas,

10” W.C.P. propane.

• Adjust main valve regulator for 6” W.C.P. natural gas,

10” W.C. P. propane.

• See periodic maintenance instructions.

• Increase inlet pressure or replace.

• Do not operate unit. See unit nameplate. Correct immediately.

Control system

overheating.

• Heater not mounted correctly.

• Heater mounted too close to ceiling.

• Mounting angle 20º-35º from horizontal.

• Observe clearance to combustibles safety chart located on heater

reflector. Do not operate unit.

Gas odor. • Loose pipe connection. • Check all connections with leak-detector solution,

tighten as necessary.

Heater cycles

repeatedly.

• Heater located in drafty area.

• Low gas pressure.

• Thermostat located in drafty area.

• Weak pilot flame.

• Relocate or shield from draft.

• See Gas Supply section for propane.

• Replace thermostat.

• Clean or adjust pilot.

No spark; no ignition. • Lack of 120V or 24V incoming voltage.

• Open high voltage wire.

• Improper electrode gap.

• Loose or open wire connection.

• Poor or no equipment ground.

• Unit in “safety lockout” mode.

• Defective “gas lighter” control.

• Proper voltage needed or repair wire.

• Isolate and ohm for resistance, replace if “0”.

• See figure 4.2.

• Check all wires, tighten or replace.

• Trace ground wire for complete circuit back to equipment ground from

control.

• Interrupt power source, repeat trial for ignition.

• Verify proper voltage. Replace.

Heater lights, and

“locks out” after

approximately 10

seconds.

• Poor or no equipment ground.

• Polarity is reversed.

• Low gas pressure.

• Electrode not sensing.

• Heater mounted at incorrect angle.

• Check all connections, provide positive earth

ground.

• 120V to black, neutral to white.

• See Gas Supply section.

• Relocate or replace if defective.

• Mounting angle 20°-35° from horizontal.

Spark is present. No

main gas operation.

Unit “locks out”.

• Gas valve in “Off” position.

• Defective main valve solenoid.

• Defective “Gas lighter” control.

• Turn to “On” position.

• Isolate and check for resistance. Replace if “0”.

• Verify proper voltage. Replace.

Heater will not

shut off.

• Defective thermostat or wiring.

• Gas valve stuck open.

• High gas pressure.

• Replace or repair.

• Replace.

• See Gas Supply section.

Chart 4.1 Troubleshooting Guide