52

Check all new water and gas piping for leaks and purge piping sections that are fi lled with air. Fix any 3)

leaks found immediately. See the National Fuel Gas Code

for additional information on testing and purging gas lines.

Vent system must be complete and free of obstructions before attempting to fi re boiler. 4)

Inspect all line voltage wiring for loose or uninsulated connections.5)

Start the boiler using the lighting instructions on page 56. After the power to the boiler is turned on:6)

Initiate a call for heat from the thermostat. Once this is done, Lamp a) 1 on the control panel (Figure

12.3) should fl ash every 4 seconds.

Rotate the Heating System Knob clockwise from “0” to the maximum supply water temperature b)

setting (at approximately 5:00) . Lamp 1 should then fl ash every two seconds and the boiler

should light after approximately 15 - 30 seconds. Once the boiler has lit, Lamps 1 and 3 will fl ash

continuously.

More information on the boiler controls and indicator lamps is presented in the Operation Section of this

manual. Note: On a new installation, there is a good chance that one of the following two problems will

occur:

The differential water pressure switch may not close. If this switch does not close after 180 seconds, •

the boiler will lockout. Lamp #2 will stay on continuously and Lamp #1 will fl ash. If this happens, look

for air in the system or insuffi cient pressure drop across the boiler supply and return connections.

If the latter problem is suspected, close the throttle valve on the supply further. If no throttling valve

is present, make sure that the fl ow restrictor is installed (See Part IX). To reset the boiler, turn the

Heating System Knob to “0” for a few seconds and then return it to the max water temperature

setting.

WARNING

Never use a fl ame to check for gas leaks.•

Make sure that the area around the boiler is clear and free from combustible materials, •

gasoline and other fl ammable vapors and liquids

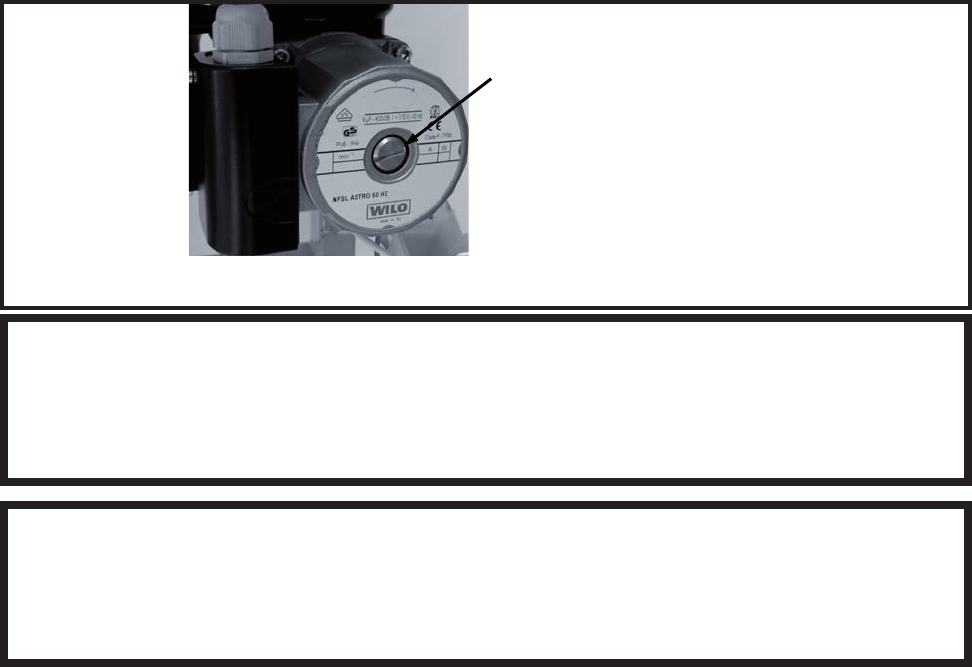

Shaft Screw Cover

Figure 12.2: Location of Circulator Shaft Cover

CAUTION

Leaks in the hydronic system can result in the addition of excessive amounts of make-

up water. This can cause severe damage to the boiler’s heat exchanger from corrosion or

calcium deposits. Repair any leaks in the system immediately.

, ANSI Z223.1.

Natural Gas and Propane Installation Code,

/NFPA 54 and/or CAN/CSA B 149.1