5

UVS33/36 Vent-Free Heaters

20002211

Clearance to Combustibles

Top of unit to ceiling ................................. 36" (914 mm)

Front of unit to combustibles ....................36' (914 mm)

Appliance

Top ......................................................... 0" (0 mm)

Bottom ..................................................... 0" (0 mm)

Sides ....................................................... 0" (0 mm)

Back ........................................................ 0" (0 mm)

Perpendicular Sidewall ....................... 6" (152 mm)

Safety Devices

Adequate combustion and ventilation air must be pro-

vided. The flow of combustion and ventilation air MUST

NOT be obstructed.

Provide adequate clearances around the air opening

into the combustion chamber; and adequate accessibili-

ty clearance for servicing and proper operation. NEVER

obstruct the front opening of the heater or cover the top

and bottom louvres (grilles).

These heaters are equipped with a pilot system fea-

turing an Oxygen Depletion Sensor (O.D.S.) shut-off

device. The O.D.S. pilot will shut down the heater when

there is not enough fresh air available.

Report any parts damaged in shipment to your dealer.

Description

The UVS vent-free heaters uses a frame window with

screen mesh that does not use any catalytic filters.

This model is available as Natural or Propane gas,

equipped with a standing pilot.

Design-certified to ANSI Z21.11.2a-2003 Unvented

Room Heaters.

The UVS33 model is shipped at 20,000 BTU/hr. It

includes orifices for operation at 15,000 and 10,000

BTU/hr. When operating at 10,000 BTU/hr, the unit is

approved for bedroom use. Based on the National Fuel

Gas Code and local codes, please match the correct

orfice size and BTU's to corresponding room size. This

conversion must not be completed in the field. Once

final rate is established, remaining orifices are to be

discarded, not left behind with the fireplace.

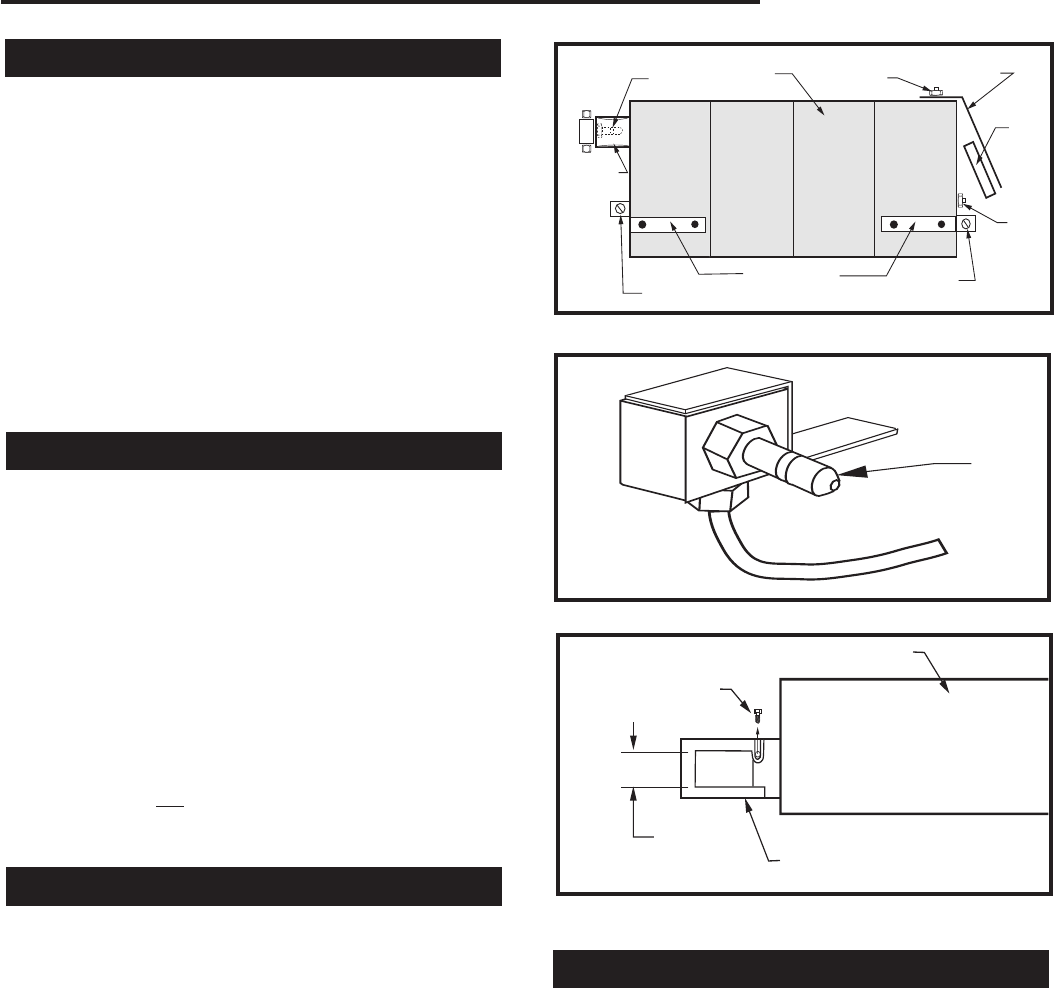

Orifice Conversion Instructions

1. Locate burner with tiles, pilot shield and orifice.

2. Unscrew two hex nuts connecting pilot shield to

burner with tiles. Move pilot shield to right. (Fig. 2)

3. Remove sheet metal screws at left and right side of

burner with tiles and remove burner.

4. Use 7/16" wrench to remove orifice. (Fig. 3) Install

desired orifice in place of orifice just removed. See

Table 3 . Use approved pipe compound for pipe

threads.

5. Remove air shutter, if necessary (Refer to Table 1),

from burner pan by removing shutter retaining screw

then air shutter. (Fig. 4)

6. Install correct air shutter on burner pan. Replace

shutter retaining screw. Adjust the air shutter to the

appropriate settings as listed in Table 1.

7. Reinstall burner with tiles and pilot shield. Check for

leaks with soapy water solution.

CO103

Gas Conversion

Air shutter

2/15/99 djt

Burner Pan

Air Shutter

Retaining

Screw

Air Shutter

Adjustment

Air Shutter

CO103

Fig. 4 Use appropriate air shutter and adjust according to

Table 1.

Front

View

CO101a

UVS33

Gas Conversion

Manifold

1/19/00 djt

Burner with

Tiles

Pilot

Log Supports

Orifice

CO101a

Fig. 2 Manifold assembly and orifice location.

Hex Nut

Air

Shutter

Pilot Shield

Sheet

Metal Screw

Sheet Metal Screw

Hex

Nut

CO102

UVS33

Orifice

Gas Conversion

1/19/00 djt

Orifice

Fig. 3 Replace orifice.

CO102