7

UVDR Series Unvented Gas Fireplaces

20007469

FP568

UVBR/CN

7/01

Finishing Material

Stud

Insulation

Noncombustible Material

Caulking or Sealant

Noncombustible

Insulation

Stand-

off

Finishing Material

Caulking or Sealant

Top View

Side View

FP568

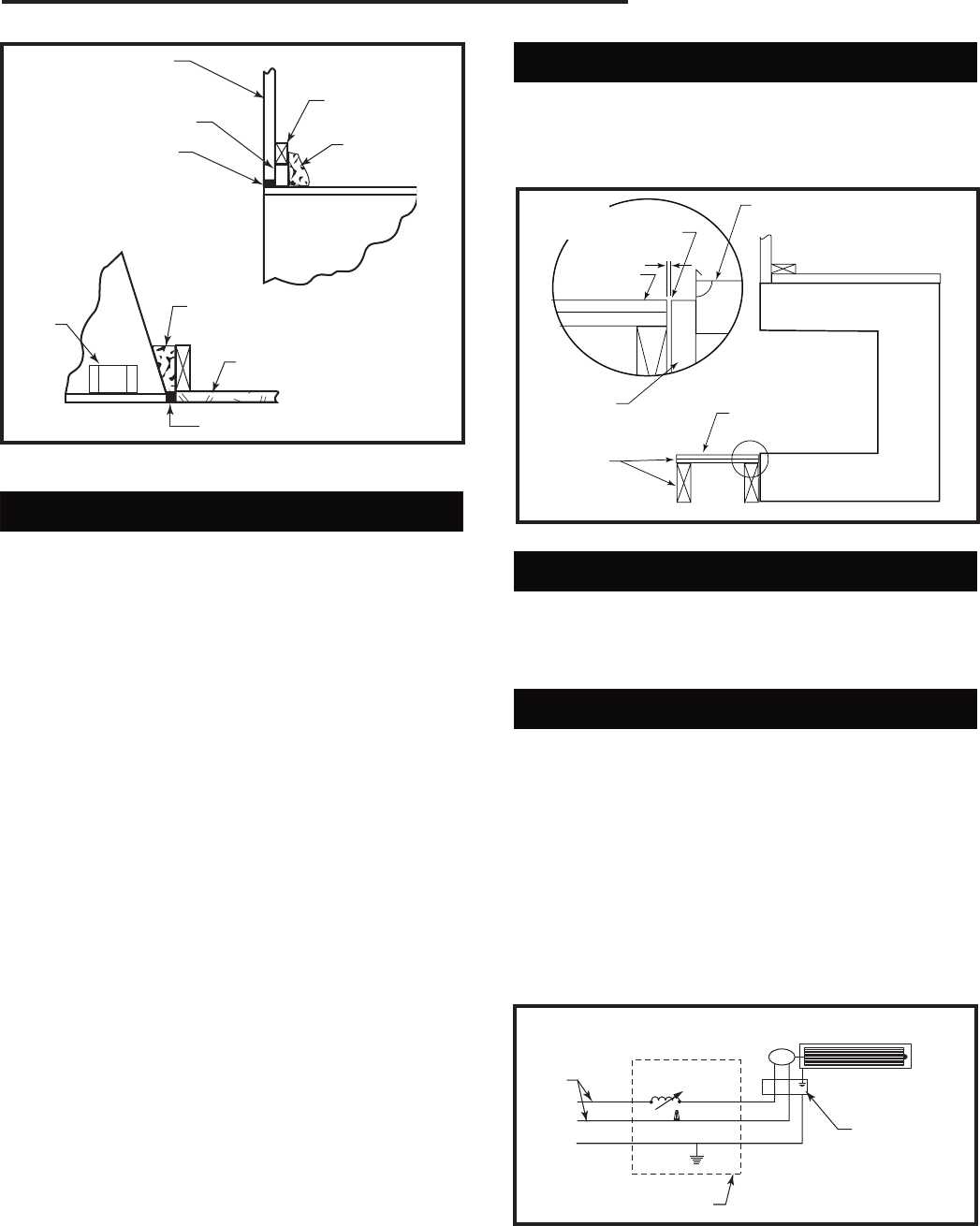

Fig. 7 Sealing spaces between fireplace and finishing materi-

als.

Finishing the Fireplace

There are a wide variety of finishing materials avail-

able for your fireplace from formal wall treatments with

marble and mantels to rustic wood paneling, stone or

brick.

IT IS IMPORTANT THAT THE BLACK FACE OF THE

FIREPLACE NOT BE COVERED WITH ANY TYPE OF

COMBUSTIBLE MATERIAL.

Noncombustible facing materials such as marble, brick

or ceramic tile may overlap the black face of the fire

-

place up to the opening on either side of the fireplace.

Seal all joints between the black fireplace face and the

wall covering with a heat-resistant material such as rock

wool insulation or mortar. Be sure to use high tempera-

ture adhesive or mortar when anchoring brick, stone or

tile to the face of the fireplace. Check to see whether

man-made brick and stone are made of noncombustible

materials before using them on the face of the fireplace.

Some of these products contain combustible materials.

Combustible wall coverings such as paneling or wall-

board may not overlap the black face of the fireplace.

The space between the wall covering and the fireplace

should be sealed with a heat-resistant material such as

rock wool insulation or mortar.

NOTE: An “L” shaped steel lintel must be installed

across the top of the firebox opening where facing

materials such as brick or stone are used on the face

of the firebox. It acts as a support/firestop. It should be

attached to the face of the fireplace with screws and

sealed to the fireplace with a heat-resistant sealer.

WARNING: The firebox screens must be in place be

-

fore operating the fireplace.

WARNING: These vent free fireplaces are not to be

used with glass doors.

Hearth Extension

A hearth extension may be used but is not required for

these fireboxes.

A raised hearth extension may be used as shown in

Figure 8.

T238

Hearth Extension

2/26/04 djt

1/2"

Hearth

Extension

Hearth Brick

Surround

Combustibles Al

-

lowed

(no carpet or vinyl)

Combustible

Plateform

T238

Fig. 8 A raised hearth extension.

Seal with Noncom-

bustible Material

Pre-Wiring of Junction Box

Wiring should be connected at the junction box located

on the right side of the firebox prior to the installation of

the blower kit. A standard wall box should be used to

contain the SCVS - Variable Speed Control Kit.

Electrical Services

If an electrical supply of 120V is being roughed in to the

fireplace junction box to provide for future installation of

optional blower kit, the wiring should be connected to

the junction box located on the right side of the firebox.

NOTE: All electric connections are to be made in ac-

cordance with CSA Standard C22.1-Canadian Electrical

Code part 1 or with the National Electrical Code, ANSI/

NFPA 70 (latest edition) and/or in accordance with local

codes.

CAUTION: Should this blower require servicing, the

power supply must be disconnected.

M

Black

White

G

T229

Blower

wiring diagram

2/11/04 djt

Firebox Acces-

sory Junction

Box

Speed Control

Switch

120

Volt

Wall Electrical Box

T229

Fig. 9 Blower wiring diagram.