6

Gas Fireplace Insert

10002964

Combustion Air

It is very important that an adequate air supply is

available when the unit is being operated. Since most

homes of today are tightly sealed and insulated, addi-

tional make-up air is usually necessary.

This fireplace has been designed to operate by drawing

air in from the front and outer perimeters of the fire-

place. The air provides combustion air ensuring a clean

burning flame, dilution air for proper venting, as well

as the air which the fan circulates over the firebox/heat

exchanger system.

NOTE: Insulating around the fireplace will result in

overheating and possible malfunctioning of the circulat-

ing fan.

Zero Clearance Applications

An alternate air supply is recommended

with this component.

For installation other than in existing woodburning fire-

places such as new construction or renovation projects,

a Zero Clearance Kit must be used. The kit enables

these inserts to be installed in combustible environ-

ments. Whenever using a Zero Clearance Kit, consid-

eration must be given to the dimensions of the Zero

Clearance Kit and the requirements of the Air Kit when

planning out the installation.

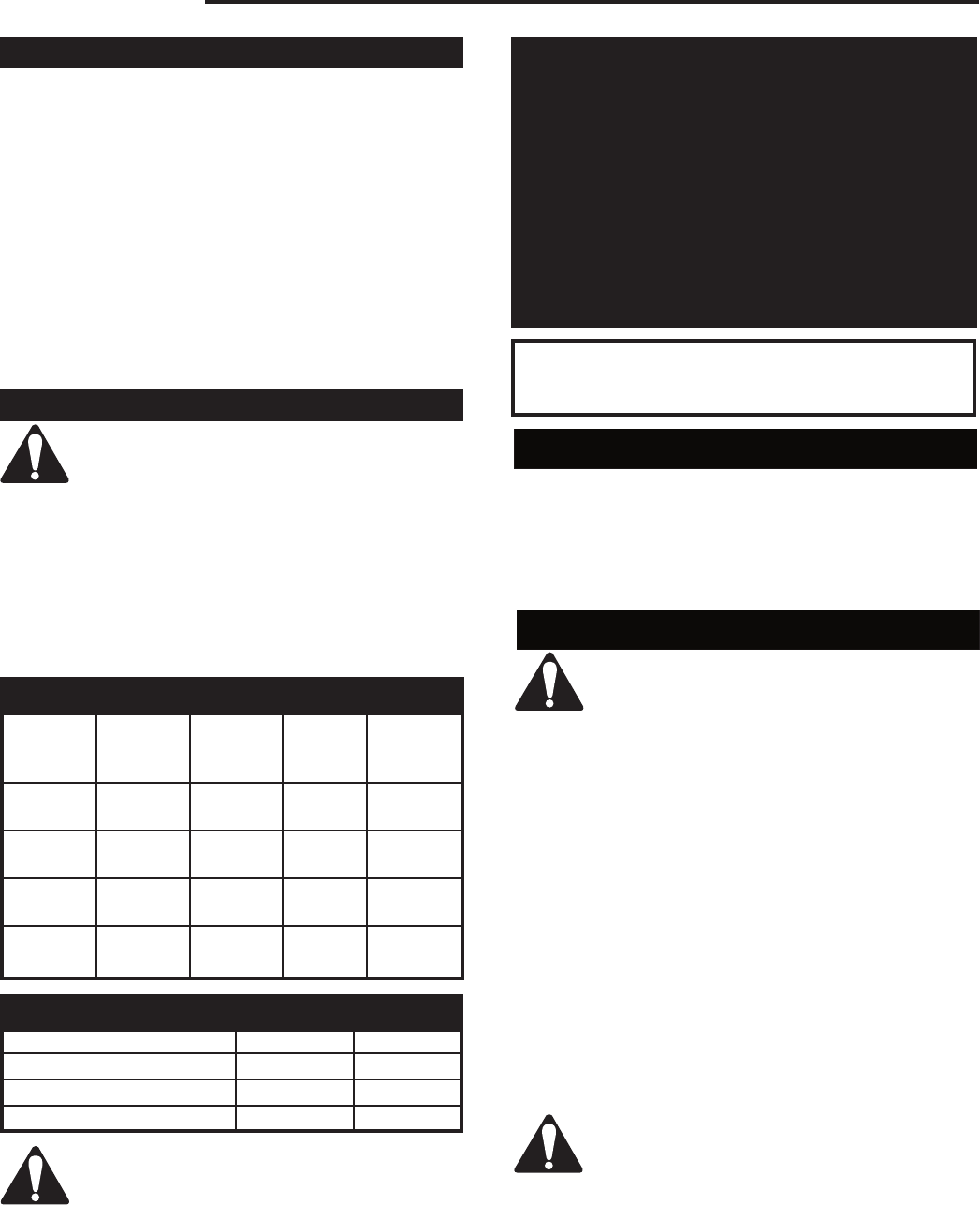

Gas Specifications

Max. Min.

Fuel Gas Input Input

Model Type Control BTU/hr BTU/hr

A125RN Natural Millivolt 20,000 14,000

Hi/Lo

A125RP Propane Millivolt 20,000 15,000

Hi/Lo

A132RN Natural Millivolt 30,000 21,000

Hi/Lo

A132RP Propane Millivolt 30,000 22,500

Hi/Lo

Natural LP

Minimum Inlet Pressure 5.5"

W.C. 11.0" W.C.

Maximum Inlet Pressure 14.0"

W.C. 14.0" W.C.

Manifold Pressure 3.5"

W.C. 10.0" W.C.

Gas Inlet & Manifold Pressures

Do not use this appliance if any part of it

has been under water. Immediately call a

qualified service technician to inspect the

unit and replace any part of the control

which has been under water.

High Elevations

Input ratings are shown in BTU per hour and are

certified without deration for elevations up to

4,500 feet (1,370m) above sea level.

For elevations above 4,500 feet (1,370m) in USA,

installations must be in accordance with the

current ANSI Z223.1/NFPA 54 and/or local codes

having jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 4,500 feet (1,370m).

These gas inserts are approved for installation

in solid fuel burning masonry or zero clearance

fireplaces.

Preparation

Before beginning, remove glass door and logs from

unit. Also check to make sure there is no hidden dam-

age to the unit. Take a minute and plan out the gas,

venting and electrical route. It is best to start with the

gas line first followed by the chimney liner. (Refer to

Page 8)

Gas Line Installation

When purging the gas line, the front glass

must be removed.

If gas piping from the source to the heater location

has not been accomplished, install the required pipe.

Consult local plumbing code to assure proper pipe size.

The gas pipeline can be brought in through the rear or

the base of the heater.

NOTE: The gas line connection can be made of either

properly tinned 3/8" copper tubing, 3/8" rigid pipe or

an approved flex connector then reduced to 3/8" to

the heater. Some municipalities have additional local

codes, it is always best to consult your local authority

and the CSA- B149.1 installation code.

U.S. Installations consult the current National Fuel

Gas Code, ANSI Z223.1/NFPA 54.

The gas control inlet is 3/8” N.P.T. therefore the 1/2”

rigid gas line must be reduced to 3/8” N.P.T. A typical

installation layout for rigid pipe is shown in Figure 4.

Always check for gas leaks with a mild

soap and water solution. Do not use an

open flame for leak testing.

The gas control is equipped with a captured screw

type pressure test point, therefore it is not necessary to

provide a 1/8" test point up stream of the control.