NOTES

1. Motor, Solenoid Valve and Dotted Control Wiring are included if

Motor and Pump package is supplied. Solenoid Valve only is sup-

plied with 99117 Water feed.

2. 1/3 HP Motor is controlled directly without use of Motor Starter.

After proper wiring and piping of boiler system is complete, testing of

controls can start. Before testing controls, it is recommended that all

contactor fusing be removed. This is to prevent possible element fail-

ure under test conditions.

CAUTION: Be sure all electrical connections are tight

before energizing boiler. Reset all manual reset con-

trols by pushing reset buttons on: (1) high limit control

located on top of boiler and (2) McDonnell-Miller locat-

ed on side of boiler.

A. McDONNELL & MILLER LOW WATER CUTOFF CON-

TROL OPERATION AND TESTING

1. Be sure all valves from incoming water supply are fully open. Turn

boiler switch to “ON” position, pump or solenoid valve will ener-

gize, allowing boiler to fill with water. Proper water level is auto-

matically reached with level control supplied. Pump or solenoid

feed will shut off at proper water level. Contactor(s) will energize,

supplying power voltage to elements.

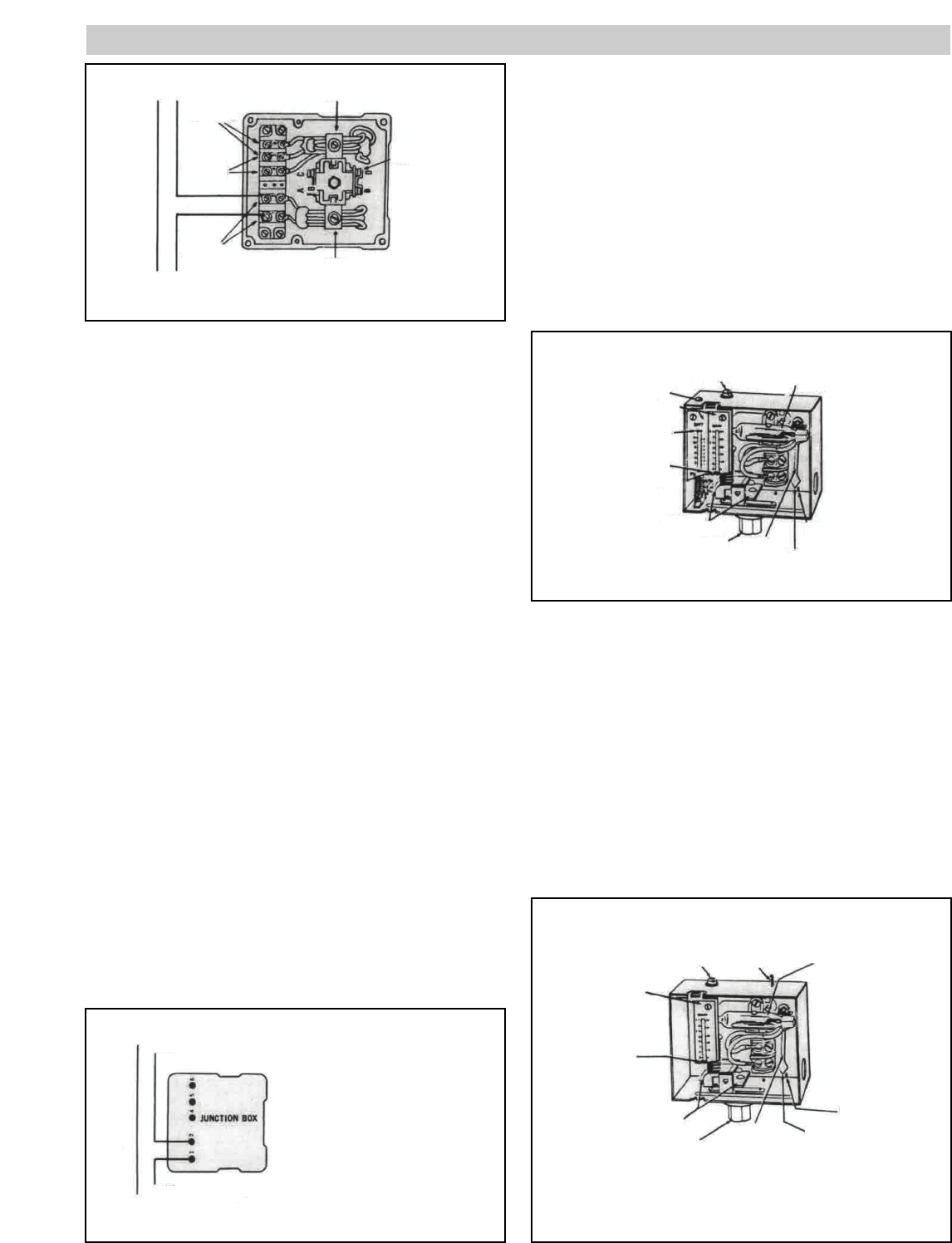

2. Checking operation of pump switch. (Figure 11) With water level

visible in sight glass, partially open drain valve at bottom of boil-

er. If automatic blowdown supplied, push manual blowdown

switch until valve open light is on, hold for few seconds. Water

level will fall, allowing float to trip pump switch to “ON” position.

Close drain valve or release manual blowdown switch. Pump

motor or solenoid valve will energize and water level will resume

to normal level in sight glass.

3. Checking low water cutout switch operation, open drain valve

completely. If automatic blowdown supplied, push in and hold

manual blowdown switch until water level falls enough to trip

cutout switch. Close drain valve or release manual blowdown

switch. If low water cutout is automatic reset, pump or solenoid

will return water level to normal. If low water cutout is manual

reset, then manual reset button on McDonnell & Miller low water

cutoff control must be pushed to complete circuit. Turn off boiler.

Reinstall contactor fuses.

B. ADJUSTING OPERATING PRESSURE CONTROLS

1. Chromalox boilers are supplied with operating and high limit pres-

sure controls. One is used for controlling the operating pressure of

the boiler while the other is used as a high limit control. To deter-

mine the difference in the controls, the high limit has a manual

reset lever on top of the case. Also, there is no differential scale

present.

2. On all controls, the pressure adjusting screw on the top of the case

sets the desired pressure. Turning the screw counterclockwise

reduces the pressure setting (see Figure 12). High limit control

should be set at 10 psig above the operating pressure of the boiler.

3. The differential adjusting screw on the operating control is set in

the same manner as the pressure adjusting screw. This scale set-

ting, plus the main scale setting, equals cutout pressure of the oper-

ating control. (Scale A thru F equals 3 psi per letter. L9l B only)

L404A Differential is indicated on Scale Plate.

To check operation of the controls, close steam outlet valve and

adjust operating pressure control to a low pressure setting. Also,

set high limit control at 10 psig above operating pressure control.

Turn on boiler and allow pressure to build up. When pressure

gauge reading approaches set point of pressure control, the switch

will trip and shut off boiler. Turn boiler main switch to “OFF".

To reset pressure control, bleed off enough pressure in the boiler

by opening steam outlet drain, or blowdown valve to allow the

operating control to reset.

4. HIGH LIMlT PRESSURE CONTROL OPERATION. The

high limit is tested in the same manner but with the operating con-

trol set above the pressure setting of the high limit. (Figure 13)

CAUTION: THIS IS FOR TEST PURPOSES ONLY!

When the high limit trips turn off boiler and reset high limit to

proper setting, the manual reset level must be pushed to resume

operation upon startup.

5

PRE-OPERATION CHECK

Pump

Line

Low Water

Cut-Off

Terminals

Alarm

Circuit

Terminals

Cut-Off and

Alarm Switch

Adjusting

Screws

Pump

Switch

Pump

Circuit

Terminals

Figure 11 – Automatic Reset Low Water Cutoff Junction Box

Pump

Line

For pump motors 1/2 h.p. Single Phase

or less, or D.C. 1/4 h.p. or less,

wire as main line switch.

Wiring Diagram – McDonnell & Miller Low Water Cutoff and Pump Control

Differential

Adjusting

Screw

Pressure

Adjusting

Screw

Mercury

Switch

Differential

Setting

Indicator

Pressure

Setting

Indicator

Operating Lever

Diaphragm Assembly

Leveling

Indicator

Pointer

Index Mark

Figure 12 – Pressure Control

Pressure

Adjusting

Screw

Manual

Reset

Lever

Mercury

Switch

Index

Mark

Pointer

Leveling

Indicator

Diaphragm

Assembly

Operating Lever

Pressure

Setting

Indicator

Scaleplate

Wiring Diagram – McDonnell & Miller Low Water Cutoff and Pump Control