ELECTRIC SHOCK HAZARD. Any installation involv-

ing electric heaters must be performed by a quali-

fied person and must be effectively grounded in

accordance with the National Electrical Code to

eliminate shock hazard.

1. Electric wiring to heater must be installed in accordance with the

National Electrical Code and with local codes by a qualified per-

son. CAUTION: Use copper conductors only.

2. When element wattages are not equal, heaters must not be con-

nected in series.

3. Electrical wiring to heater should be contained in rigid conduit or

in sealed flexible conduit to keep corrosive vapors and liquids out

of the terminal enclosure. If high humidity is encountered, the con-

duit should slope away from the heater.

4. If flexible cord is employed, a watertight connector should be used

for entry of the cord into the terminal enclosure. Outdoor applica-

tions require liquid-tight conduit and connectors.

5. Bring the power line wires through the opening in the terminal

enclosure.

6. Heaters are prewired and tagged for easy installation of electrical

wiring to the heater. Tagging of the individual circuits of

Chromalox Industrial Over-The-Side Immersion heaters is shown

in the following tabulations. Refers to Type TLC, TLO, TLS, TLI,

KTLC, KTLO, KTLS, KTLI, KBLC, KBLS, BLCK, and BLCS

Series heaters.

7. Make sure heater, is grounded by attaching ground conductor,

traceable back to service entrance, to the ground terminal located

inside the terminal enclosure. If heater is used in an electroplating

tank, the heater should be grounded externally to the tank wall to

minimize stray plating currents in heater sheath that may cause

sheath corrosion.

8. Check for loose terminal connections and tighten if necessary.

Made to order items are prewired and tagged at the factory. Wiring

of made to order items may differ from those shown in the tabu-

lations. Carefully check voltage and phase on the heater name-

plate and select either the appropriate wiring shown above or

check for the appropriate wiring diagram in the heater termi-

nal enclosure. For reference purposes, some typical wiring dia-

grams are shown in the following figures.

5

WIRING

WIRING DIAGRAMS – TLC, TLO, TLS, TLI

120V 120V 240V 240V 480V 480V 480V 120V 120V 240V 240V 480V 480V 480V

Model 1ø 3øΔz 1ø 3øΔz 1ø 3øΔz 3øY Model 1ø 3øΔz 1ø 3øΔz 1ø 3øΔz 3øY

Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig.

TLC, TLI and TLS 210 — — 1 — 1 — — TLO 310 — — 3 4 3 4 —

TLC, TLI and TLS 212 — — 1 — 1 — — TLC, TLI and TLS 312 — — 3 4 3 4 —

TLC, TLI, TLO and TLS 220 1 — 1 — 2 — — TLC, TLI and TLS 315 — — 3 4 3 4 —

TLO 230 1 — 1 — 1 — — TLC, TLI and TLS 318 — 3 4 3 4 —

TLC, TLI, TLO and TLS 240 1 — 1 — 1 — — TLC, TLI, TLO and TLS 330 3 4 3 4 5 4 6

TLO 250 1 — 1 — 1 — — TLO 345 3 4 3 4 3 4 —

TLC, TLI, TLO and TLS 260 1 — 1 — 1 — — TLC, TLI, TLO and TLS 360 3 4 3 4 3 4 —

TLO 270 — — 1 — 1 — — TLO 375 3 4 3 4 3 4 —

TLC, TLI and TLS 280 — — 1 — 1 — — TLC, TLI, TLO and TLS 390 3 4 3 4 3 4 —

Note: Use wire size and type specified by NEC.

480V heaters require 600V wire per NEC.

480V heaters require a contactor.

Contactor and wiring supplied by customer.

INSTALLATION (cont’d.)

9. To prevent moisture accumulation in cryogenic applications or

when heater is exposed to freezing temperatures:

A. Slope conduit away from enclosure (drip loop).

B. Seal all conduit openings to moisture/explosion resistant ter-

minal enclosure.

C. Insulate terminal enclosure.

FIRE OR SHOCK HAZARD. Moisture accumulation

in the element refractory material, element over-

temperature, or sheath corrosion can cause

ground fault to the element sheath, generating arc-

ing and molten metal. Install Ground Fault Circuit-

Interrupter (GFCI) to prevent personal injury or

Equipment Ground Fault Protection to prevent

property damage.

10. Heaters with floor flange:

A. Remove electrical enclosure.

B. Mount heater to tank or manhole cover.

C. Install electrical enclosure.

Fittings into electrical enclosure must be properly

sealed to prevent contamination of electrical con-

tacts from vapors.

FIRE OR EXPLOSION HAZARD. If the heater is not

properly submerged, the heating elements will over-

heat and could result in a fire or damaged equipment.

NOTE: If heating in closed vessels, controls and

backup controls must be used to prevent buildup of

temperature and/or pressure. Maximum pressure

rating is 50 PSI.

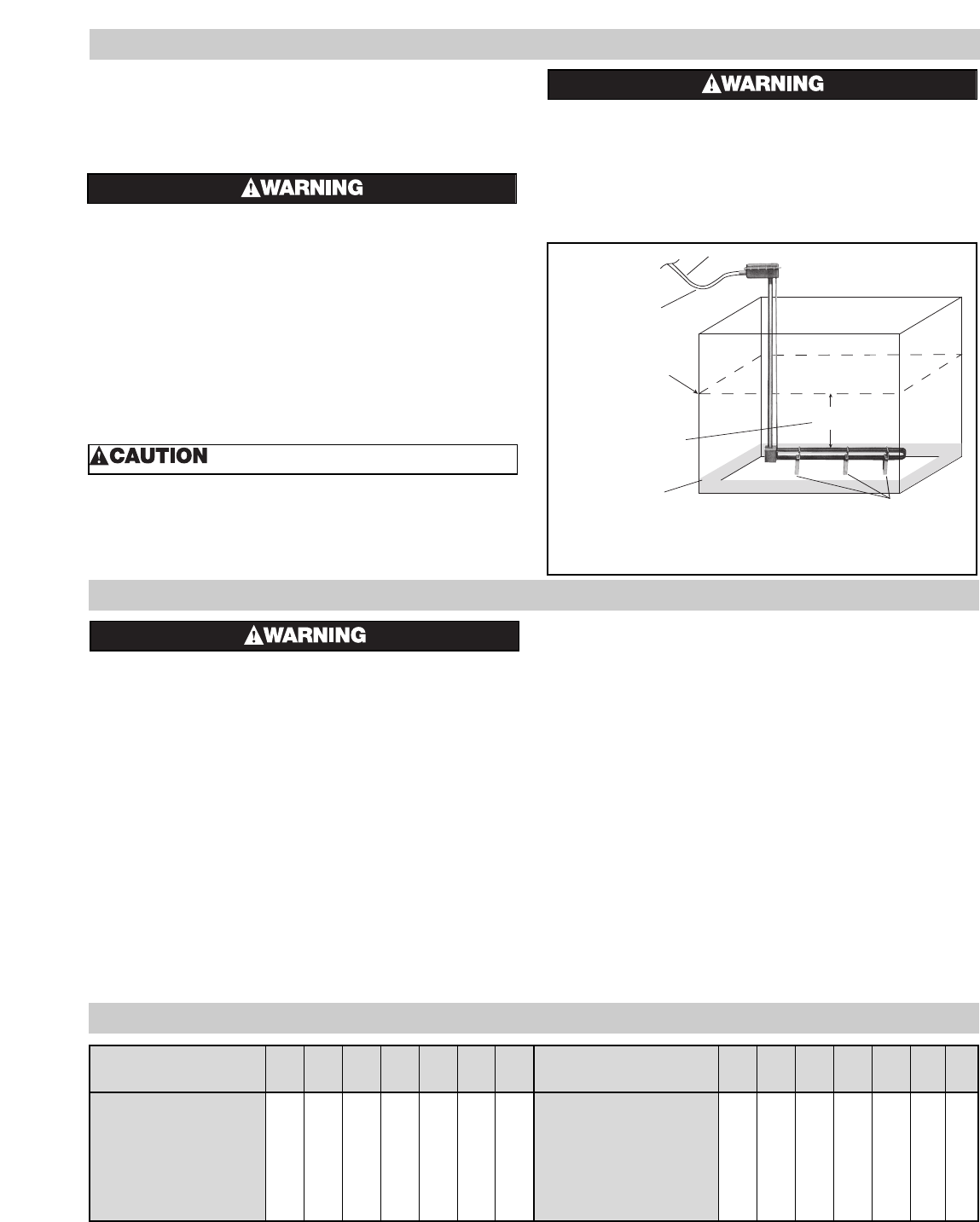

Drip Loop recommended to

minimize passage of moisture

along wiring into terminal

wiring connections.

Expected Low Liquid Level

Always maintain a minimum of

6 to 8" of liquid above the heated

portion of the element to prevent

exposure of the effective

heated length.

Expected maximum

sediment level

Sludge Legs

NOTE: Locate the heater as low as possible for maximum

heated liquid storage capacity. Heat does not move downward.

6 to 8"

Minimum

Suitable Wiring

FIGURE 3 Open Tank Illustration

!