2

Specifications –

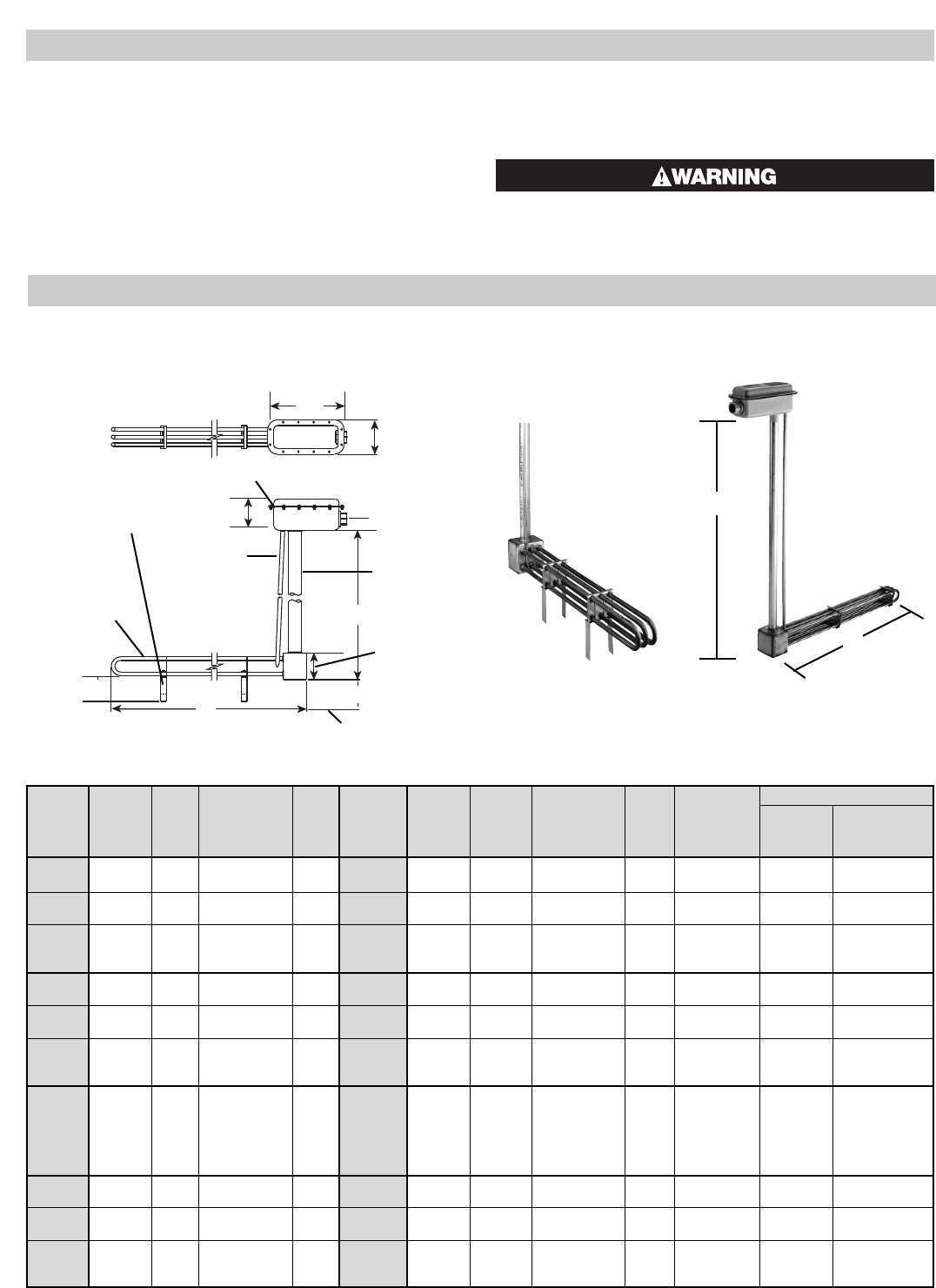

Dimensions (In.)

(A) (B)

No. No. Sheath Min. Tank

Model Elements Phase Volts kW Model Elements Phase Volts kW Material Riser Height Opening Clearance

TLC-210 2 1 240-480 10 TLC-315 3 1 or 3Δ 240-480 15 Copper 48 45

TLC-212 2 1 240-480 12 TLC-318 3 1 or 3Δ 240-480 18 Copper 48 52-1/2

TLC-220 2 1 120-240-480 2 TLC-330 3

1 or 3Δ 120-240

3 Copper 36 12-1/4

1 or 3Y 480

TLC-240 2 1 120-240-480 4 TLC-360 3 1 or 3Δ 120-240-480 6 Copper 36 22-1/4

TLC-260 2 1 120-240-480 6 TLC-390 3 1 or 3Δ 120-240-480 9 Copper 36 29-1/2

TLC-280 2 1 240-480 8 TLC-312 3 1 or 3Δ 240-480 12 Cooper 36, 48 37-3/8

TLI-210 2 1 240-480 10 TLI-315 3 1 or 3Δ 240-480 15 Incoloy 48 45

TLI-212 2 1 240-480 12 TLI-318 3 1 or 3Δ 240-480 18 Incoloy 48 52-1/2

TLI-220 2 1 120-240-480 2 TLI-330 3

1 or 3Δ 120-240

3 Incoloy 36 12-1/4

1 or 3Y 480

TLI-240 2 1 120-240-480 4 TLI-360 3 1 or 3Δ 120-240-480 6 Incoloy 36 22-1/4

TLI-260 2 1 120-240-480 6 TLI-390 3 1 or 3Δ 120-240-480 9 Incoloy 36 29-1/2

TLI-280 2 1 240-480 8 TLI-312 3 1 or 3Δ 240-480 12 Incoloy 36, 48 37-3/8

TLO-220 2 1 120-240-480 2 TLO-330 3 1 or 3Δ 120-240-480 3 Steel 36 22-1/4

TLO-230 2 1 120-240-480 3 TLO-345 3 1 or 3Δ 120-240-480 4.5 Steel 36 29-1/2

TLO-240 2 1 120-240-480 4 TLO-360 3 1 or 3Δ 120-240-480 6 Steel 36, 48 37-3/8

TLO-250 2 1 120-240-480 5 TLO-375 3 1 or 3Δ 120-240-480 7.5 Steel 48 45

TLO-260 2 1 120-240-480 6 TLO-390 3 1 or 3Δ 120-240-480 9 Steel 48 52-1/2

TLO-270 2 1 240-480 7 TLO-310 3 1 or 3Δ 240-480 10 Steel 48 56-1/2

TLS-210 2 1 240-480 10 TLS-315 3 1 or 3Δ 240-480 15 Stainless Steel 48 45

TLS-212 2 1 240-480 12 TLS-318 3 1 or 3Δ 240-480 18 Stainless Steel 48 52-1/2

TLS-220 2 1 120-240-480 2 TLS-330 3

1 or 3Δ 120-240

3 Stainless Steel 36 12-1/4

1 or 3Y 480

TLS-240 2 1 120-240-480 4 TLS-360 3 1 or 3Δ 120-240-480 6 Stainless Steel 36 22-1/4

TLS-260 2 1 120-240-480 6 TLS-390 3 1 or 3Δ 120-240-480 9 Stainless Steel 36 29-1/2

TLS-280 2 1 240-480 8 TLS-312 3 1 or 3Δ 240-480 12 Stainless Steel 36, 48 37-3/8

(A)

(B)

Note: Thermostat shipped separately in kit. See page

with renewal parts for ordering information.

(10)

(A)

(B)

(4)

(4-1/2)

(3-1/2)

3-1/2 approx.

Tank Bottom

1”–11-1/2 NPT

Tube Riser

Gasket

Thermostat Well

Heating Elements

Sludge Leg/s

Assemble

As Shown

(See Installation)

(4-1/16)

TLC, TLO, TLS, TLI

SPECIFICATIONS

GENERAL (cont’d.)

D. Riser type construction puts the heat at the bottom inducing

natural “stirring action” and evenly distributed temperatures.

E. Units are available with E1 General Purpose, E4 Moisture

Resistant, E2 Explosion/Moisture Resistant and E3 Explosion

Resistant terminal enclosures.

IMPORTANT: It is the responsibility of the purchaser of

the heater to make the ultimate choice of sheath

material based upon his knowledge of the chemical

composition of the corrosive solution, character of

the materials entering the solution, and controls

which he maintains on the process. CHROMALOX

cannot warrant any electric immersion heater against

failure by sheath corrosion if such failure is the result

of operating conditions beyond our control.

Sheath corrosion can result in a ground fault which,

depending upon the solution being heated, can cause

an explosion or fire.