Draft Barrier Heater Installation (Wall)

1. Once the correct mounting height is established, scribe or snap

a level line on the wall to maintain each heater back plate in

horizontal alignment, when mounting.

2. Remove heater front cover by lifting top rear edge to unsnap

cover from back plate (store cover in safe location to avoid

damage to the finish). (See Figure 2).

3. Remove all appropriate knockouts from terminal boxes, partic-

ularly terminal box end knockouts when installing continuous

run heating. (See Figure 3).

4. Mount the back panel to the wall using suitable fasteners (not

supplied). Should the wall surface be uneven, secure the heater

backplate to the high spots only to avoid a distorted appearance.

Draft Barrier Heater Installation (Floor)

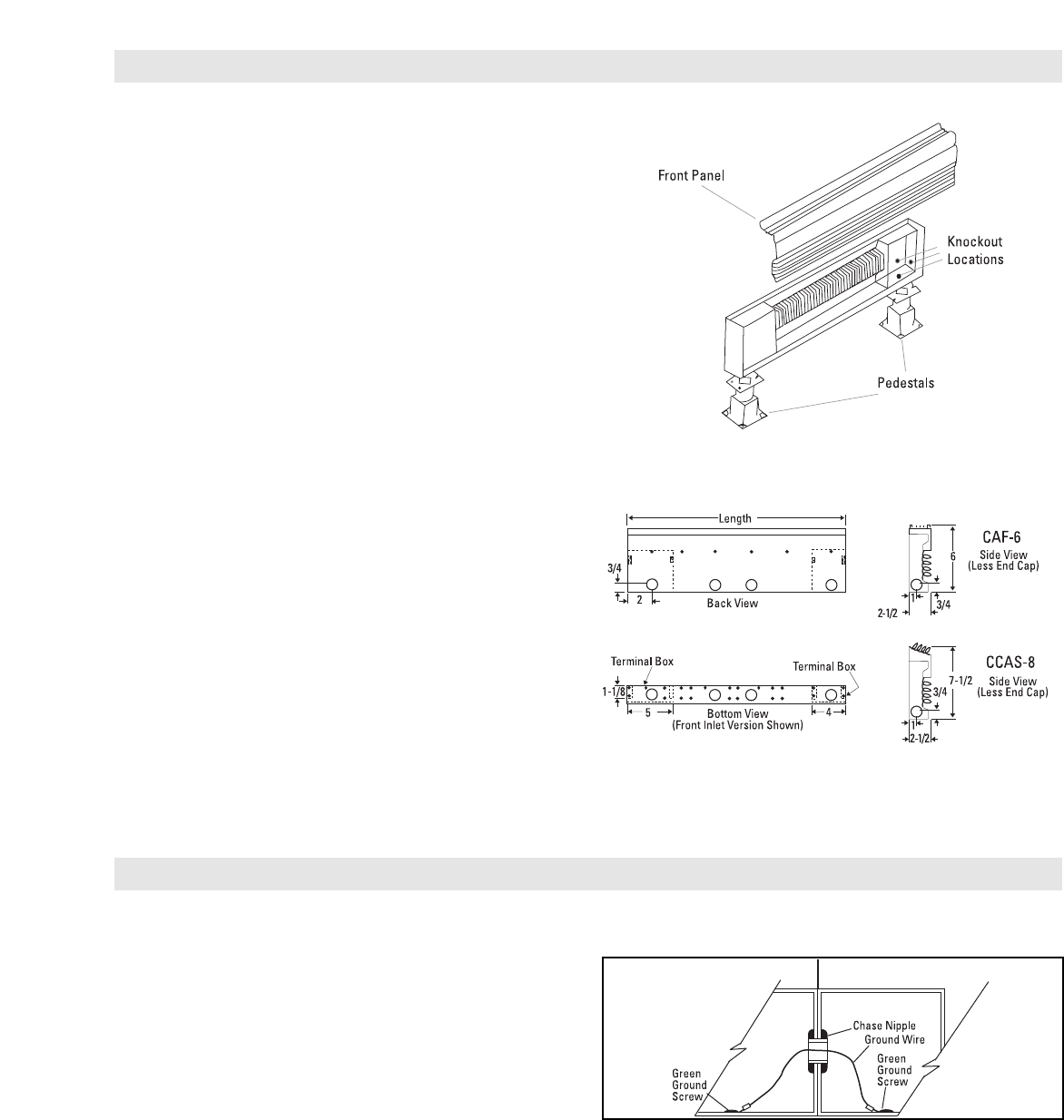

1. Unpack the heater and pedestal(s) from the carton (The

pedestals are packed at the end of carton) and lift the front/top

panels up and off the heater.

2. Disassemble the pedestal base from the pedestal pad.

3. Remove the desired terminal box cover(s) and supply wire

entry knockouts from the terminal boxes.

4. Secure a pedestal to each end of the heater bottom with #8

screws provided aligning the back and front edges of the pad

with the heater. This will align the supply entry knockout with

opening in pedestal pad.

TIP:

Units longer than 4 feet will be provided with 3 or more

pedestals. The extra pedestals should be used to support the

middle of heaters.

5. Place heater on the pedestal base(s) and tighten all screws.

TIP:

The height of the heater can be adjusted on the pedestal to

aid in leveling the heater by loosening the securing bolt at the

side of the pedestals.

6. Remove the terminal box cover and proceed to wiring instructions.

GENERAL

WIRING

Ground Continuity —

WARNING: Hazard of Electric Shock. Any installa-

tion involving electric heaters must be effectively

grounded in accordance with the National

Electrical Code to eliminate shock hazard.

Prior To Installation —

WARNING: Hazard of Electric Shock. Disconnect all

power before installing heater.

1. All branch circuit and service supply wiring must be complet-

ed to the heater terminal box location.

2. Check heater nameplate ratings to be sure heater voltage is

same as service supply.

3. Service supply entry is usually made to one heater terminal box

(see Figure 3) with through wiring (Factory Installed) being

used for interconnection of all heaters in a continuous run

installation.

Note: When heaters are mounted end to end, remove the finishing

end plate, install a chase nipple and locknut in the terminal box

end knockout to ensure grounding continuity and to protect the

wiring.

Where heaters are spaced apart, remove the finishing end plate,

and use rigid conduit (Provided by customer) for through wiring

and ground continuity. Do not exceed the allowable number of

conductors allowed by the National electrical code.

Note: See Table 3 for recommended service supply wire sizes.

4. Knockouts are provided at the back, bottom and ends of all

heater backs (see Figure 3). Terminal boxes are located at both

ends of every heater.

Figure 3

Figure 2

Figure 4