If the appliance is used to heat a very

small central heating system then the

heat output to the room from the fire

will be reduced. Fig. 3. shows the

ratio of space heating to water

heating which can be expected.

Fitting a radiator in the same room as

the fire is recommended as it will

allow greater flexibility in the way

that the system is operated as well as

ensuring that there is sufficient heat.

Connect the heating system to the

boiler ensuring that the primary flow

pipe rises continuously from the

appliance to the vent. Fill the system

with water and check for leaks.

SYSTEM CONTROLS

Since the controls on the stove are

manually operated we strongly

recommend using high and low limit

pipe thermostats to control the pump.

The high limit, (anti-boiling,)

thermostat, should be fitted on the

gravity flow pipe as near to the boiler

as possible, and the low limit,

(anti-condensation,) thermostat

should be fitted on the gravity return

- again as near to the boiler as

possible but ensuring that it is not on

the common part of the return if only

one return tapping is used. Set the

high limit thermostat at 85°C and the

low limit thermostat at 45°C.

Radiators may be either manually or

thermostatically controlled.

CONNECTIONS TO

FLUES

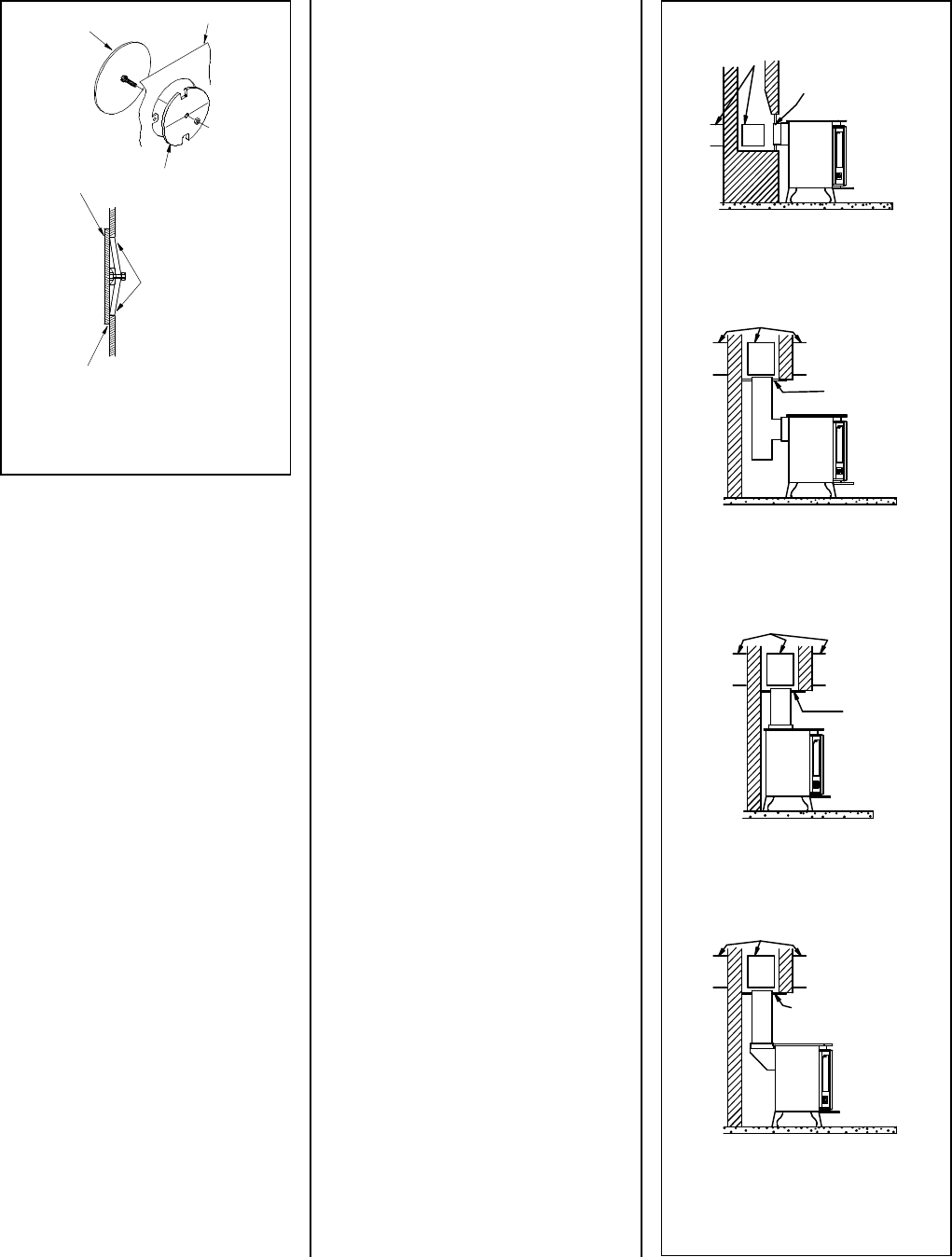

There are several ways of connecting

the stove to the flue. These are

illustrated in Figs. 8 to 11.

If the top flue connection, or the

optional vertical rear flue connector,

is used then chimney may be swept

through the appliance.

Horizontal lengths of flue must be

kept to a minimum and should not be

more than 150mm (6 inches) long.

The sealing face of the flue collar

must be coated with fire cement

before fixing to the body of the stove

using the two screws provided. The

blanking plate must be removed,

sealed with fire cement and refitted,

care being taken to ensure that the

fold on the blanking plate is in line

with the lugs on the firebox as shown

in Fig. 7. Ensure that the clamping

plate does not prevent the throat plate

from seating correctly. All flue

connections must be well sealed.

SOOT DOORS

It is possible to pass a 16 inch

diameter sweeps brush through the

appliance but in most back outlet

installations it will be necessary to

have a soot door to enable the

chimney to be swept. The optional

vertical rear flue connector does

allow the chimney to be swept

through the stove.

Soot doors may either be in the actual

brickwork of the chimney or in the

register plate. Various positions of

soot doors are shown in Figs. 8 to 11.

PRE LIGHTING

CHECK

Ensure that the throat plate is fitted

Blanking Plate

Blanking Plate

Clamping Plate

with fold horizontal

Back of the Stove

Clamping plate finishes

flush with inside face of

firebox top and bottom.

with fire cement

Seal Blanking Plate

Fig. 7. Flue Blanking Plate.

With Bricked Up Fireplace

Of Chimney

Soot Door

In Side or Rear

Register Plate

Soot Door

Alternative

Positions

With Top Flue Connection

Soot Door

Alternative

Positions

With Optional Vertical Rear Flue

Connector

Soot Door

Alternative

Positions

Register Plate

With Soot Door

Register Plate

With Soot Door

Register Plate

With Soot Door

With Rear Flue Connection

Fig. 8. Vertical Register Plate

Fig. 9. Horizontal Register Plate

Fig. 10. Horizontal Register Plate

Fig. 11. Horizontal Register Plate

Page 8

Country 8B WB 10/00