with the centre-line of the chimney,

and must also extend to the point

where the chimney narrows to its

final size. Any large voids must be

filled and flaunched to the flue pipe

to ensure that all soot deposits can be

cleared when the appliance is swept.

Ensure that the flue pipe is not

obstructed or restricted in any way

and that all joints are well sealed.

Before infilling cover the front of the

fire to protect it. Ensure that the flue

pipe is central and then fill the space

between the body of the fire and the

structural brickwork with vermiculite

(eg. micafil or similar) concrete.

Ensure that there are no air pockets.

The recommended mix is six volumes

of vermiculite granules to one volume

of portland cement thoroughly mixed

together. Enough water should be

added so that no more than one or

two drops of water are released when

a handful of the mixture is squeezed.

After filling with vermiculite flaunch

the top of the flue connector pipe to

the chimney with lime mortar.

Make good the holes in the front and

side of the chimney breast making

sure that they are completely airtight.

A typical installation is shown in

Fig. 10.

In most installations it will be

possible to sweep the chimney

through the appliance. If this is not

possible then some alternative means

(such as a soot door), must be

provided.

The free-inset method of installation

may be used instead of in-filling.

Details are available on request.

THERMOSTAT

Before lighting the fire check the cold

setting distance of the thermostat.

With the control knob at the

maximum setting the flap should be

18 mm from the air inlet as shown in

Fig. 11. To adjust the distance

slacken the locking nut and adjust as

necessary. When set correctly

re-tighten the locking nut. Ensure that

the flap opens and closes freely as the

knob is turned.

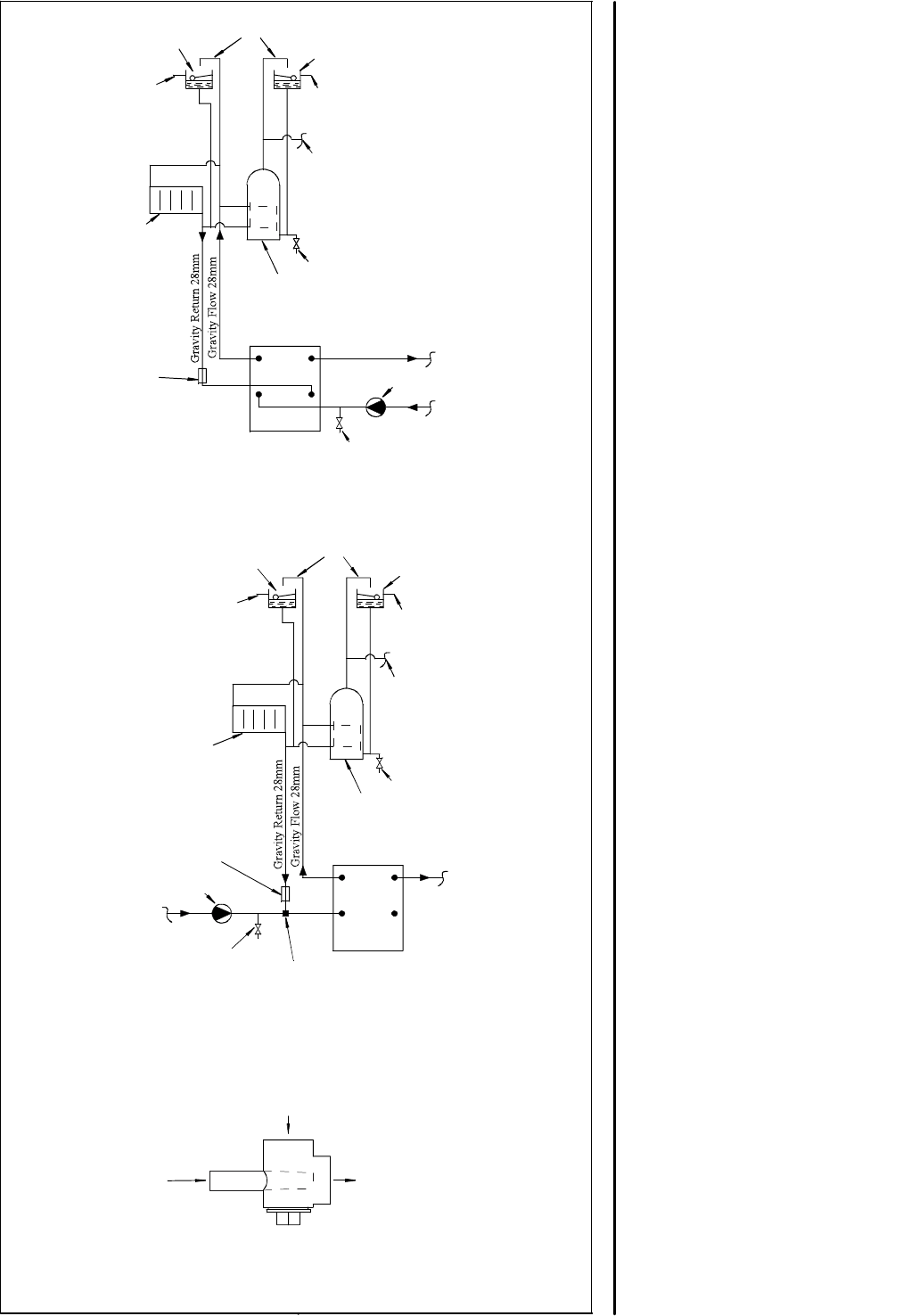

Central Heating Flow

Central Heating Return

Drain Cock at Lowest Point

Drain Cock

IndirectHotWater Cylinder

Cold Water Tank

Overflow

Feed and Expansion Tank

22mm Open Vents

Gravity Radiator

CirculatingPump

Central Heating Return

Drain Cock at Lowest Point

Drain Cock

IndirectHotWater Cylinder

Domestic HotWater Draw Off

Cold Water Tank

Overflow

Overflow

Feed and Expansion Tank

22mm Open Vents

GravityRadiator

CirculatingPump

Injector Tee

MinimumReturn Thermostat

Gravity Return

(28mm Pipe)

Central Heating Return

Common Return to Boiler

Central Heating Flow

MinimumReturn

Thermostat

(28mm Pipe)

Overflow

Domestic HotWater Draw Off

Fig.7TypicalCentralHeatingandHotWaterSystem

Using4BoilerTappings

Fig. 8. Typical Central Heating & Hot Water System

Fig. 9. InjectorTee.

Using 3 Tappings

Page 9

LA30iB 3.99