5

Vermont Castings Vigilant

2000898

Weak draft situations are characterized by smoking

and odor problems in the house, low heat output, and

difficulty maintaining a fire, especially at low thermostat

settings. The reverse situation, overdraft, is rare, but

can be recognized by short burn time, poor response

when trying to slow down the fire, or by any part of the

stove glowing red.

A more common cause of overdraft is inadequate

maintenance, such as worn gasket allowing uncon-

trolled air to enter the stove. Following recommended

maintenance procedures will ensure consistent stove

performance.

Following the stove manufacturer’s recommendation on

both chimney size and height will also help ensure ad-

equate chimney flow capacity. Flow capacity measures

the ability of the chimney to evacuate combustion gas-

es quickly. Even the strongest draft cannot overcome

an insufficient flow capacity; the result is a back up of

combustion gases in the chimney which forces smoke

out of chimney connector joints or the stove itself. Re-

member, the Vigilant and the chimney must function as

a unit. For optimum performance, they must be sized

properly for each other. Your Vermont Castings Autho-

rized Dealer can help you assess your existing chimney

or plan a new one for best stove operation.

Chimney Guidelines

DO NOT CONNECT TO ANY AIR DISTRIBU-

TION DUCT OR SYSTEM.

New Chimneys

Both masonry and prefabricated metal chimneys work

well.

A new prefabricated metal chimney should be one test-

ed and listed for use with solid-fuel burning appliances

to the High-Temperature (H.T.) Chimney Standard UL-

103-1985 (2100° F.) and have interior walls especially

designed for use with coal-burning stoves. Be sure to

follow the chimney manufacturer’s instructions exactly

when passing the chimney through a combustible wall

or ceiling. Special accessories may be necessary for

this type of installation.

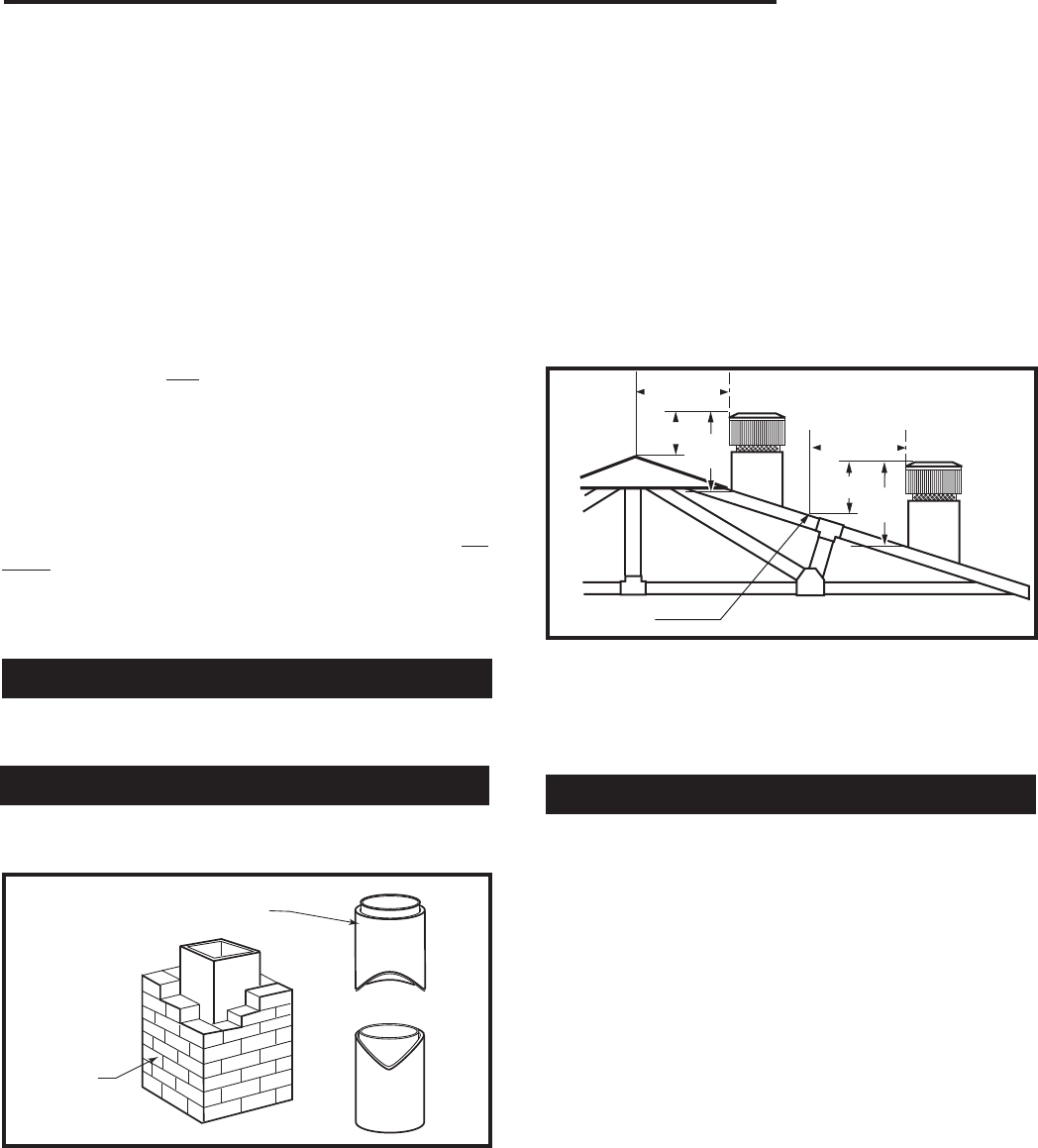

The chimney should extend at least 3 feet above the

highest point where it passes through a roof, and at

least 2 feet higher than any portion of a building within

10 feet.

ST241

chimney types

12/13/99 djt

Prefabricated Double-

wall Insulated Chimney

Tile-lined

Masonry

Chimney

ST241

Fig. 2 Chimney types.

A new masonry chimney should be constructed to con-

form to the standards of your local building code or a

recognized national code. Masonry chimneys must be

lined with code-approved masonry or pre-cast refrac-

tory tiles, stainless steel pipe suitable for use with coal,

or a code-approved poured-in-place liner. The chimney

must have a tight sealing clean-out door.

For proper draft and good performance, any chimney

used with a Vermont Castings wood or coal burning

stove should extend at least 16 feet above the flue col-

lar of the stove.

Existing Chimneys

An existing masonry chimney may work well, but be

sure to have it carefully inspected before using it. De-

fects may have gone unnoticed if the chimney previ-

ously was used only occasionally. Defects must be

repaired before the chimney is used with your stove.

If you are not sure that you can make the inspection

yourself, your local professional chimney sweep, build-

ing inspector, or fire inspector will be able to make the

inspection or direct you to someone who can.

The chimney should be thoroughly cleaned before be-

ing used with your stove.

First, check to see that the chimney has a lining. Do

not use an unlined chimney. Your local Vermont Cast-

ings Authorized Dealer or chimney sweep can help

you with information about approved chimney lining

systems. In addition, look for and repair (if necessary)

these defects: (Fig. 4)

A. Improper chimney height and roof clearance; check

local building codes for proper construction.

B. Chimney cap deterioration; rebuild.

C. Creosote stains indicate flue damage; inspect and

repair.

2' Min.

2' Min.

3'

Min.

0 To 10'

3'

Min.

0 To 10'

AC617

RLTSKC8

2/11/98

Reference

Point

AC617

Fig. 3 The 2’-3’-10’ chimney rule.