7

NVC Series B-Vent

20000194

Gas Line Installation

When purging gas line the fornt glass

must be removed. Purging gas lines must

comply with ANSI Z223.1/NFPA 54 in USA

and CSA B149.1 in Canada.

The gas pipeline can be brought in through the right or

left side of the appliance, as well as the bottom. Knock-

outs are provided at convenient locations to allow for

the gas pipe installation and testing of any gas connec-

tion. It is most convenient to bring the gas line in from

the right side, as this allows fan installation or removal

without disconnecting the gas line.

The gas line connection can be made with properly

tinned 3/8" copper tubing, 1/2" rigid pipe or an approved

flex connector, then reduced to 3/8" (R Models) or 1/2"

(E Models) to the appliance. Because some municipali-

ties have some additional local codes, it is always best

to consult your local authority and the CSA-B149.1

installation code.

For US installations consult the current National Fuel

Gas Code, ANSI Z223.1/NFPA 54 .

Always check for gas leaks with a mild

soap and water solution applied with a

brush no larger than 1" (25mm). Never

aply soap and water solution with a spray

bottle. Do not use an open flame for leak

testing.

The fireplace valve must not be subjected

to any test pressures exceeding 1/2 psi.

Isolate or disconnect this or any other

gas appliance control from the gas line

when pressure testing.

The gas control is equipped with a captured screw type

pressure test point, therefore it is not necessary to

provide a 1/8" test point up stream of the control.

When using copper or flex connector use only approved

fittings. Always provide a union so that gas line can

be easily disconnected for burner or fan servicing.

Refer to gas specification for pressure details and

ratings. NOTE: If flex connector is used, it must be kept

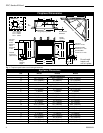

inside of the appliance. (Fig. 5)

Remote Switch Installation

1. Thread wire through the electrical knockout located

on either side of unit. Do not cut wire or insulation on

metal edges. Ensure that wire is protected. Run the

other end to a conveniently located wall receptacle

box.

2. Attach wire to switch and install switch into receptacle

box. Attach cover plate to switch.

3. Connect wiring to gas valve. (Figs. 19 or 20, Page

14)

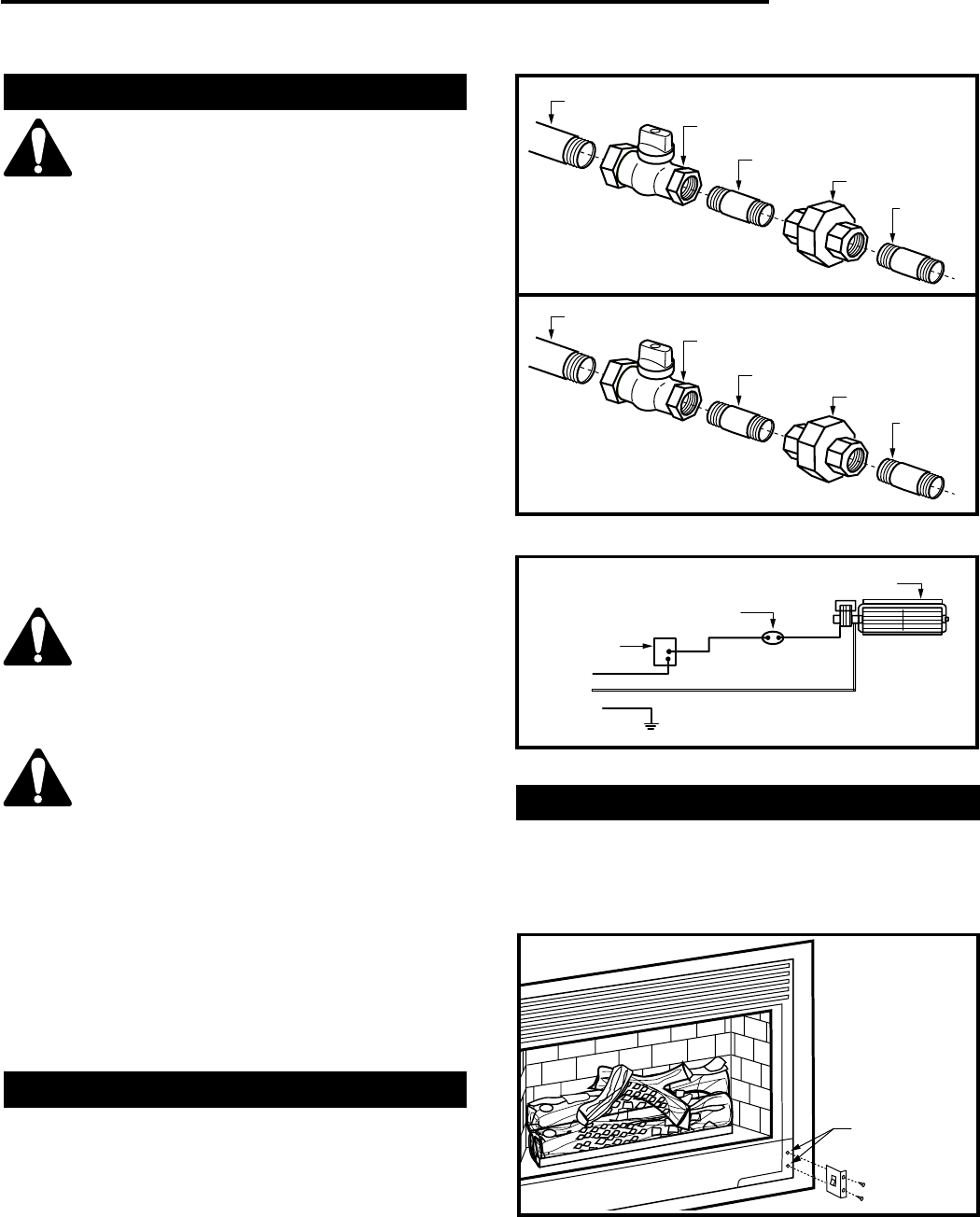

Alternate Switch Location

Remote switch can be installed on either side of the ac-

cess door. Simply mount the switch to the switch bracket

provided. Screw the bracket on either side of the frame,

lining up the screws with the pre-punched holes. (Fig. 7)

Fig. 5 Typical gas supply installation.

FP413

1/2" Gas Supply

1/2" x 3/8" Shut-off Valve

3/8" Union

3/8" Nipple

3/8"

Nipple

1/2" Gas Supply

1/2" x 1/2" Shut-off Valve

1/2" Union

1/2" Nipple

1/2"

Nipple

"R" Model

Supply Line

"E" Model

Supply Line

Fig. 6 Wiring diagram.

FP394

Black

White

Ground

Fan

Temperature

Sensor

Speed

Control

Fig. 7 Installing remote switch bracket.

FP381

Pre-punched

Holes