16

Vermont Castings EWF30

20008662

Side Wall Protection

Adjacent combustible side walls that are within mini-

mum dimensions shown in Figure 25 of the fireplace

opening must be protected with CFM Corporation Wall

Shield Model SP40 or a specifically built wall shield

described in Figure 20.

The special wall shield design described in Figure 20 is

an alternate method of adding protection to side walls

and can be used in place of the SP40 with the same

wall clearances specified for the SP40. Rt must =1.85

minimum.

Examples of wall shield insulation:

1. Manville - CERAFORM 126, K=.27,

1/2 inches thick

2. EH2416, K = .458,

1 inch thick required.

Hearth Installation

A hearth extension is required to protect a combustible

floor in front of the fireplace. Refer to Figure 26 for mini-

mum dimensions and mounting detail.

NOTE: Hearth Extension must not cover the air

inlet opening of a fireplace.

The hearth extension described in Figure 26 must be a

durable noncombustible material with a minimum (total)

Rt value of 1.09; see Figure 24 for examples. The over-

all height (above a combustible floor), depth and width

must be as indicated, with the extension centered to the

fireplace opening.

The top of insulation must be covered with a non-com-

bustible decorative covering or a piece of .018” mini-

mum sheet metal, to protect hearth extension material.

(Fig. 26)

Secure the hearth extension to the floor to prevent

shifting, using trim molding or other similar means at

three (3) outer edges. Seal crack between the fireplace

hearth and hearth extension with a noncombustible

material. (Figs. 25 and 26)

WARNING: Hearth extension must be installed in

accordance with Figure 25. Top of hearth extension

must be level with bottom of fireplace.

Alternate noncombustible materials may be used

providing the (total) thermal resistance (Rt value) of the

alternate material employed is greater than or equal to

R = 1.09 Thermal resistance (R) or thermal conductivity

(K), may be obtained from manufacturer of the material.

Factors are related by the formula K = 1/R. (Fig. 24)

T = given thickness

R = thermal resistance for a given thickness (T)

K = thermal conductivity

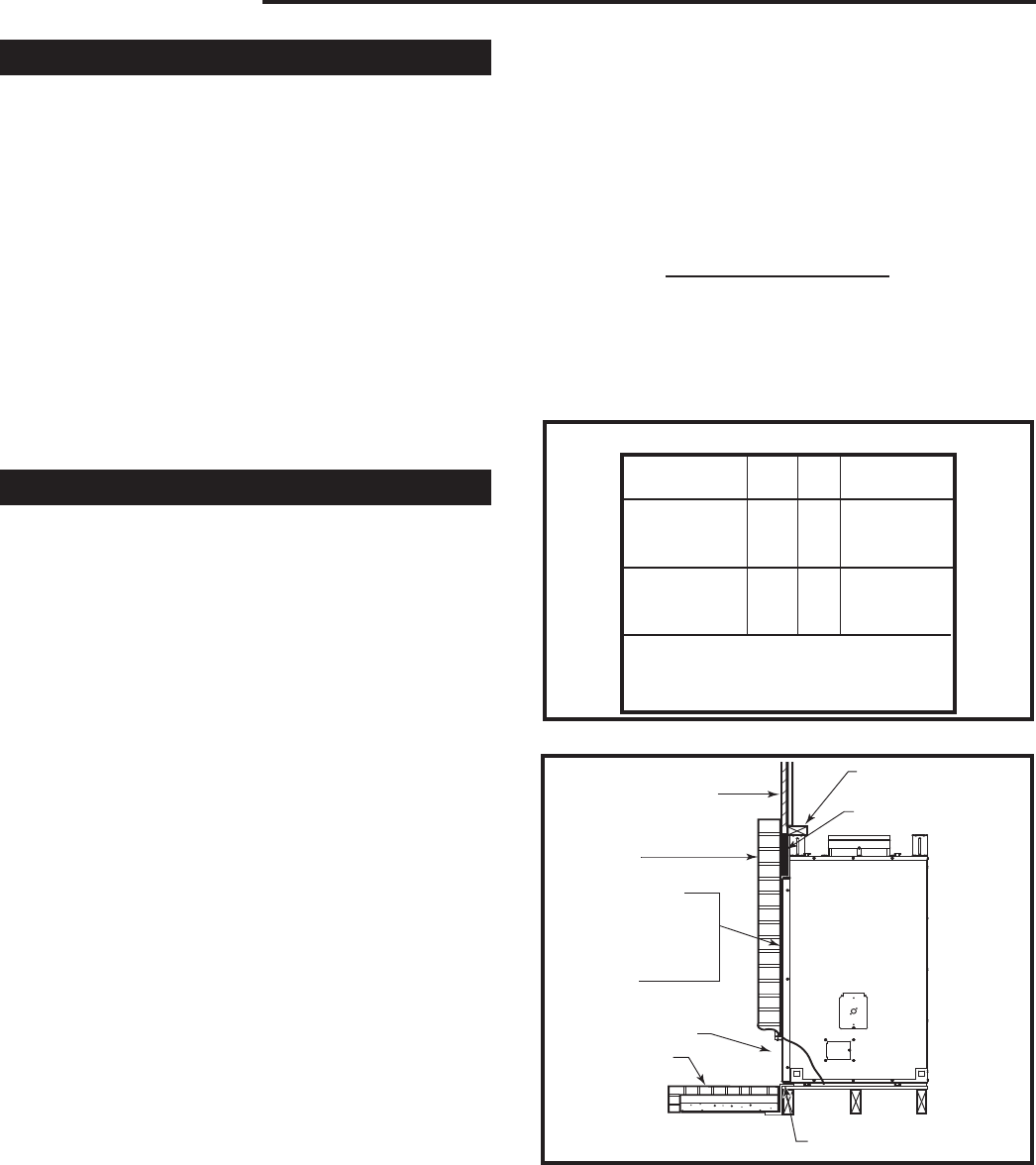

COMMON MATERIALS AND FACTORS

MATERIAL K*

R

MINIMUM

THICKNESS

EH2416

Common Brick

0.916

5.0

2.18 1.0 in.**

0.10 5.46 in.**

(CFM Corporation)

R Value is for 1/2 inch.

* Units of K = BTU/SQ FT/HR/˚F/IN

** Thickness of Listed Material

FP533ADD

Addendum

6/1/99 djt

8/4/99 changed .2 to .1

one inch to 1/2 inch djt

FP533ADD

Fig. 24 Hearth extension material factors.

NEW K of new material (per inch) thickness

required = X of listed

thickness K of listed material (per inch) material

FP1202a

EWF30

SEALING DETAILS

6/05

Wall Covering

2 x 4 Header - Do not

notch at standoffs

Noncombustible

Decorative

Facing

Seal all cracks

between fireplace sur-

round (steel) and wall

materials with noncom-

bustible material.

Cast Front

Noncombustible

Decorative

Covering

Safety Strips - Must be

overlapped 1/2” minimum

FP1202a

Fig. 25 Sealing gaps.

NOTE: No

material

may cover

black cast

face.

Noncombustible

Material

Noncombustible material with a lower R value may

be used, provided thickness of material is sufficiently

greater to maintain an equivalent (total) thermal resis-

tance (Rt).

Example of Determining Hearth Extension Equiva-

lents

To determine the thickness required for any

new mate-

rial:

Example for Common Brick

T (new) = 5.0/0.458 x 0.50 in. =

5.46 in. (new required

thickness).