9

Voltage to compressor terminals during operation must be

within voltage range indicated on unit nameplate (see Table 2).

On 3-phase units, voltages between phases must be balanced

within 2% and the current within 10%. Use the formula shown

in the legend for Table 2, Note 2 to determine the percent of

voltage imbalance. Operation on improper line voltage or ex-

cessive phase imbalance constitutes abuse and may cause dam-

age to electrical components. Such operation would invalidate

any applicable Carrier warranty.

FIELD CONTROL WIRING — Install a Carrier-approved

accessory thermostat assembly according to installation in-

structions included with the accessory. Locate thermostat

assembly on a solid wall in the conditioned space to sense aver-

age temperature in accordance with thermostat installation

instructions. Connect thermostat wires to terminal board.

Route thermostat cable or equivalent single leads of colored

wire from subbase terminals through connector on unit to low-

voltage connections (shown in Fig. 12).

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American

Wire Gage) insulated wire (35 C minimum). For 50 to 75 ft,

use no. 16 AWG insulated wire (35 C minimum). For over

75 ft, use no. 14 AWG insulated wire (35 C minimum). All

wire larger than no. 18 AWG cannot be directly connected to

the thermostat and will require a junction box and splice at the

thermostat.

Feed control wires through the raceway located between the

condenser coil top cover and burner side panel. See Fig. 10.

Connect control wires to corresponding screw terminals, the

low-voltage connections located inside low-voltage access

panel. See Fig. 12 for connections. The low-voltage connec-

tions provide the UL required clearance between high- and

low-voltage wiring.

HEAT ANTICIPATOR SETTINGS — Set heat anticipator

settings at .14 amp for the first stage and .14 amp for second-

stage heating, when available.

CONDENSER

COIL

TOP COVER

INTAKE

LOUVERS

CORNER POST

FLUE HOOD

END PANEL

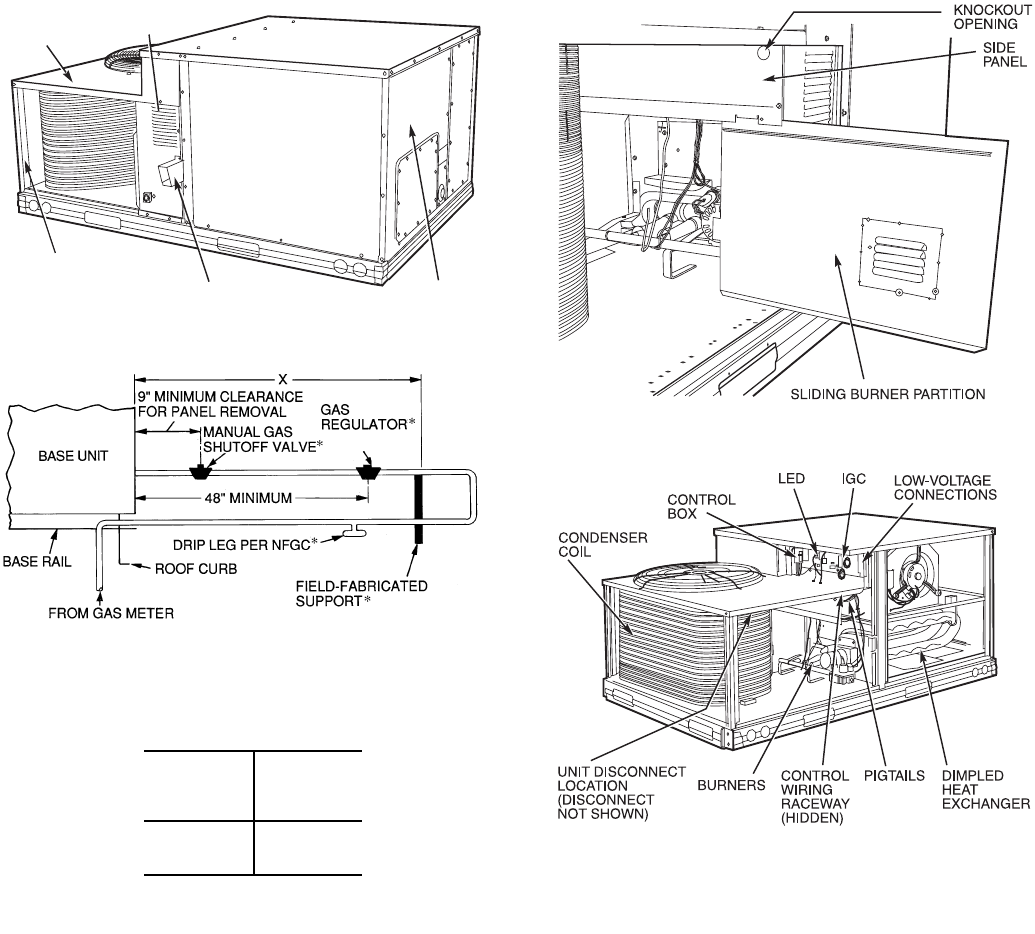

Fig. 8 — Gas Piping Guide (With Accessory

Thru-the-Curb Service Connections)

SPACING OF SUPPORTS

STEEL PIPE

NOMINAL

DIAMETER

(in.)

X

DIMENSIONS

(feet)

1

/

2

3

/

4

or 1

1

1

/

4

or larger

6

8

10

LEGEND

*Field supplied.

NOTE: Follow all local codes.

NFGC —

National Fuel Gas Code

Fig. 7 — Flue Hood Details

Fig. 9 — Conduit Installation

LEGEND

Fig. 10 — Component Location

IGC —

Integrated Gas Unit Controller

LED —

Light-Emitting Diode